Loop circuit compensating circuit used for Buck converter

A compensation circuit and converter technology, applied in the field of electronics, can solve the problems of reducing capacitor resistance area, large resistance and capacitance, difficult on-chip integration, etc., to reduce chip area and cost, small capacitance value, easy on-chip integration, etc. integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

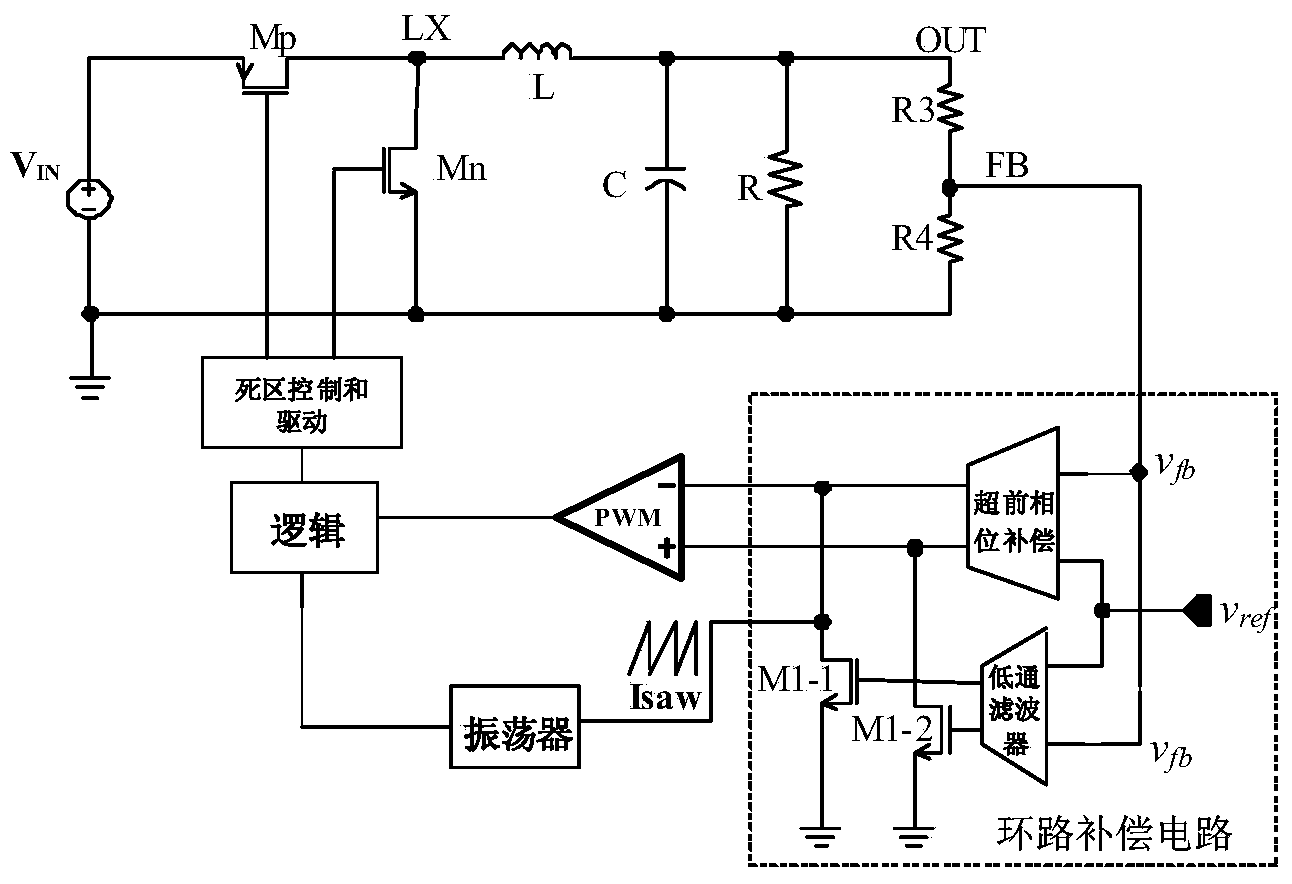

[0026] The principle of the loop compensation circuit of the present invention will be described below in conjunction with the accompanying drawings.

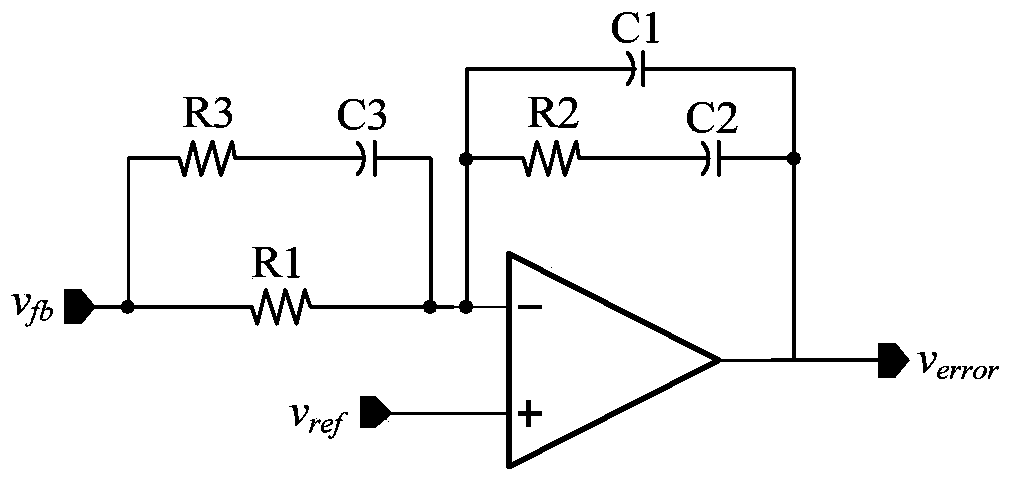

[0027] A loop compensation circuit for Buck converter, its structure is as follows figure 2 As shown, it includes an advanced phase compensation circuit, a fully differential low-pass filter and two NMOS transistors M1-1 and M1-2.

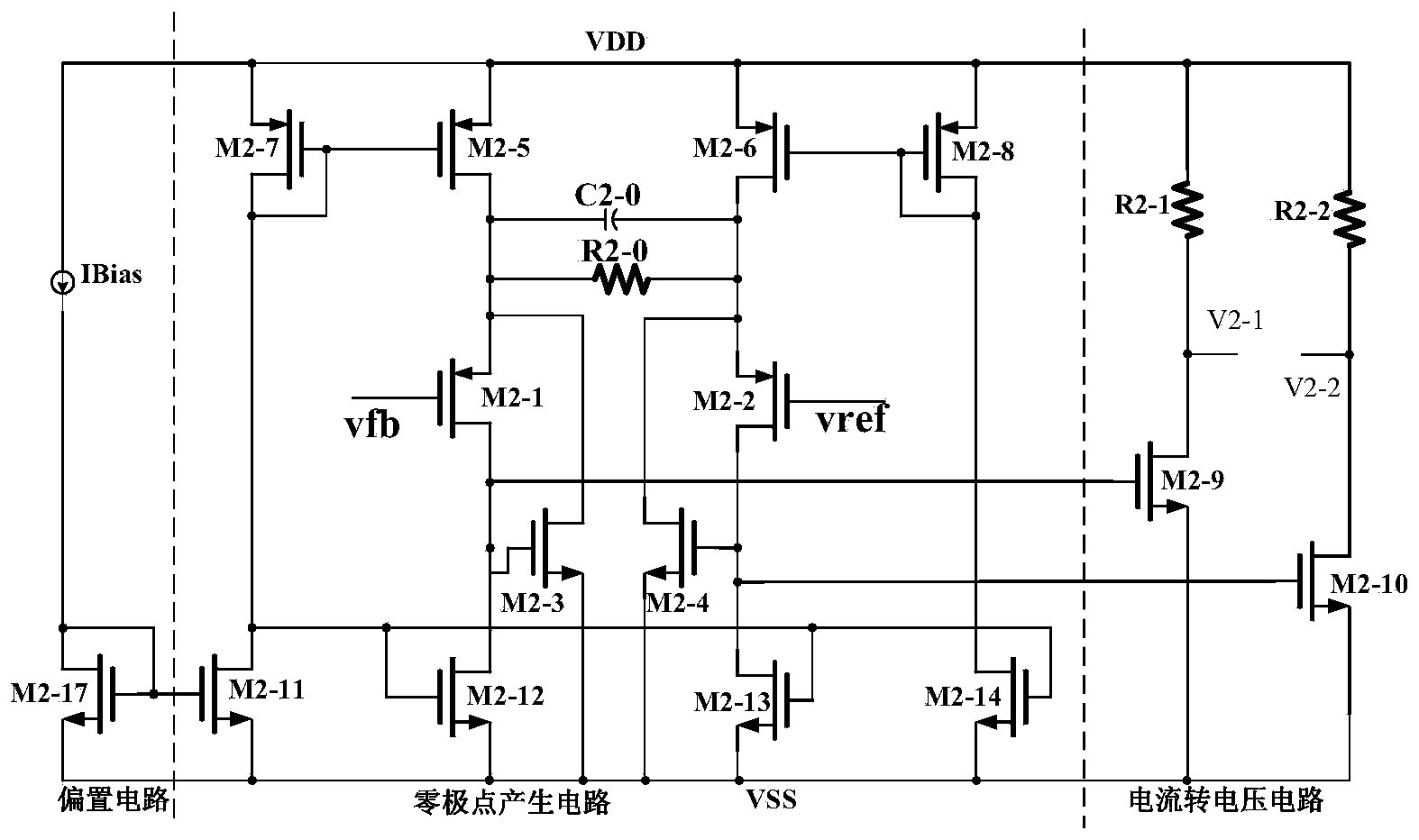

[0028] The lead phase compensation circuit, such as image 3 As shown, it consists of a first bias circuit, a pole-zero generating circuit and a current-to-voltage circuit. The lead phase compensation circuit generates a zero and two high frequency poles to provide lead phase compensation.

[0029] The first bias circuit is composed of a first current bias source IBias and an NMOS transistor M2-17; the first bias current source IBias is connected across the power supply VDD and the drain of the NMOS transistor M2-17, and the NMOS transistor M2- 17 The gate is short-circuited to the drain, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com