Tea-frying machine

A tea frying machine and frame technology, which is applied in the field of tea making tools, can solve the problems of low mechanization, efficiency improvement, and low precision, and achieve the effects of good safety, small size, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

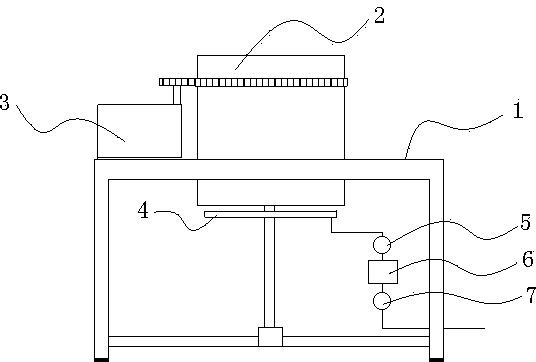

[0011] according to figure 1 As shown, the tea frying machine in the present invention includes a frame 1 , a cylinder body 2 , a cylinder body driving device 3 , an excitation coil 4 , a high-frequency power conversion module 5 , a controller 6 and a coil voltage control module 7 .

[0012] Wherein, the cylinder body 2 is horizontally rotatably mounted on the frame 1 through a rotating shaft,

[0013] It also includes an excitation coil 4 , a high-frequency power conversion module 5 , a controller 6 and a coil voltage control module 7 connected in sequence.

[0014] The excitation coil 4 is arranged below the cylinder body 2 and leaves a gap with the cylinder body 2. The outer wall of the cylinder body 2 is provided with a ring of teeth, and the cylinder driving device 3 contains The meshed gears drive the barrel 2 to rotate, and when the excitation coil 4 is connected to an alternating current, an alternating magnetic field is generated, and the barrel 2 in the alternating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com