Energy-saving control method of hydraulic system of hydraulic rolling shear

A hydraulic system, energy-saving control technology, applied to fluid pressure actuated system components, shearing devices, shearing equipment, etc., can solve problems such as pressure oil leakage, hydraulic system oil temperature rise, and electric energy waste, so as to improve the use of Efficiency, reducing power loss, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

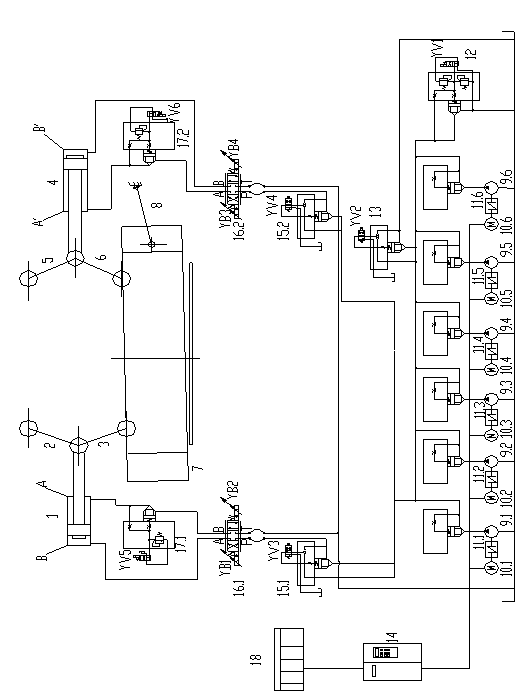

[0010] Such as figure 1 As shown, press the cutting start button, the rolling shears start to cut the steel plate, and the PLC programmable controller 18 controls the frequency converter 14 to make the frequency conversion motors 10.1, 10.2, 10.3, 10.4, 10.5, 10.6 drive the column according to the given speed The plug pumps 9.1, 9.2, 9.3, 9.4, 9.5, and 9.6 supply oil to the system. At the same time, the electromagnet YV1 of the plug-in relief valve 12 is energized, the hydraulic system is loaded, and the system pressure rises. The plug-in electromagnetic check valve 15.1 The electromagnet YV3 is energized, and the pressure oil enters the rodless chamber B of the hydraulic cylinder 1 through the pressure oil port P of the servo proportional valve 16.1, and pushes the piston rod to move to the right. When the piston rod of the hydraulic cylinder 1 reaches the required position , the electromagnet YV2 of the plug-in electromagnetic directional control valve 13 is energized, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com