Three-dimensional glass and method for manufacturing the same

A manufacturing method and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as glass sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

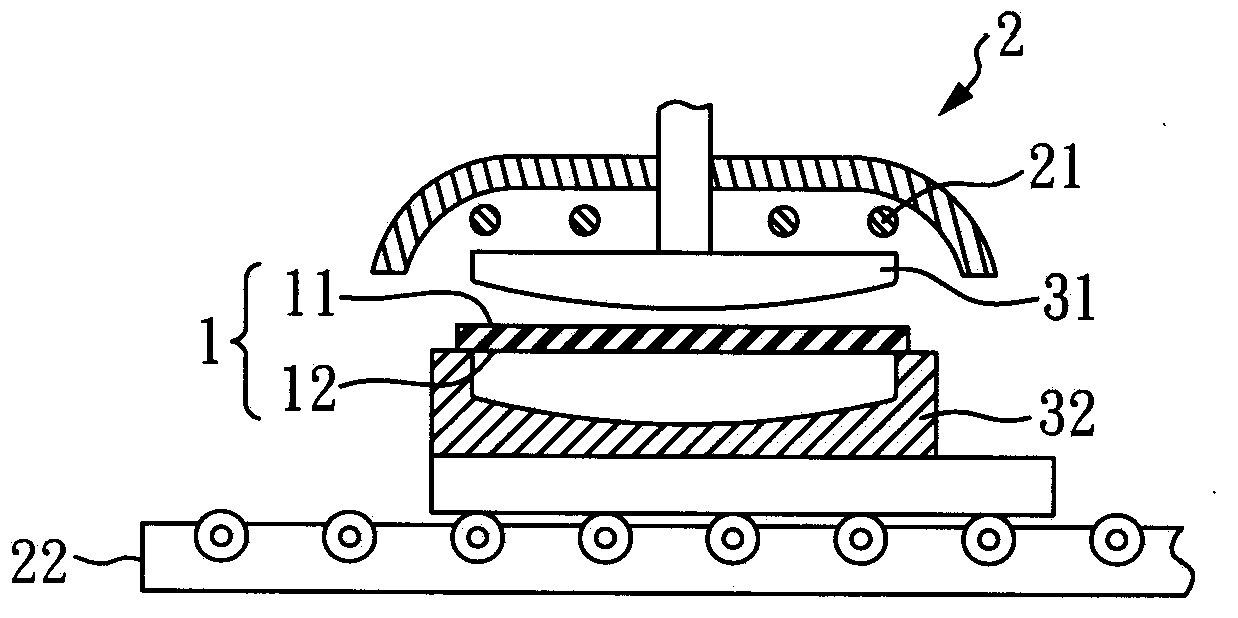

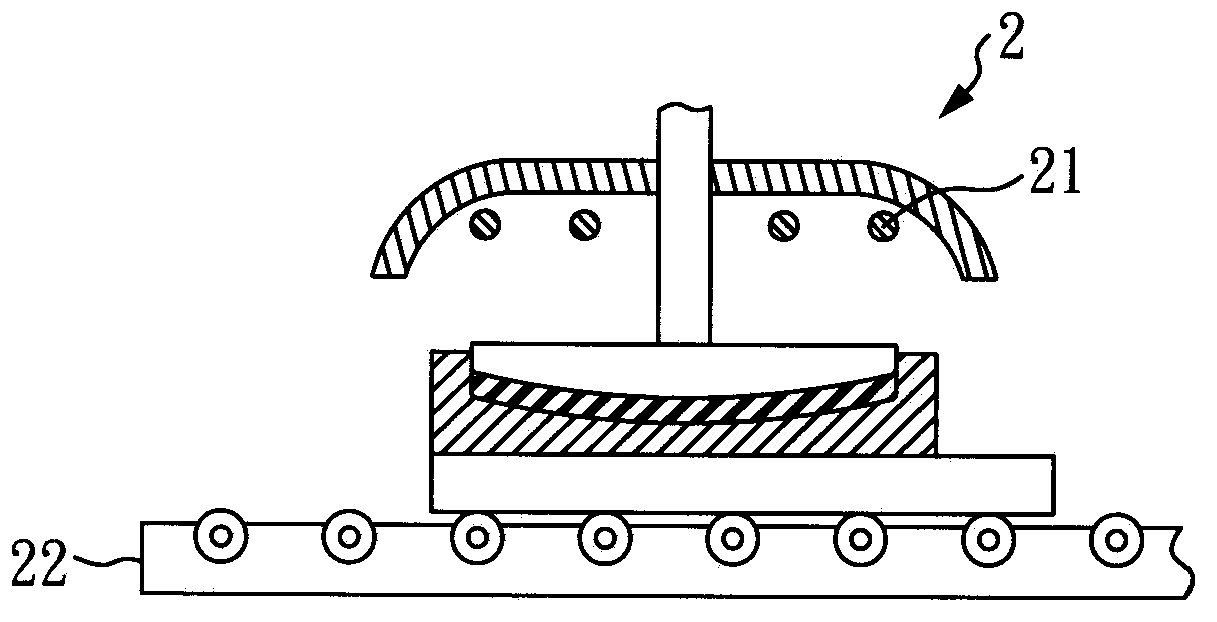

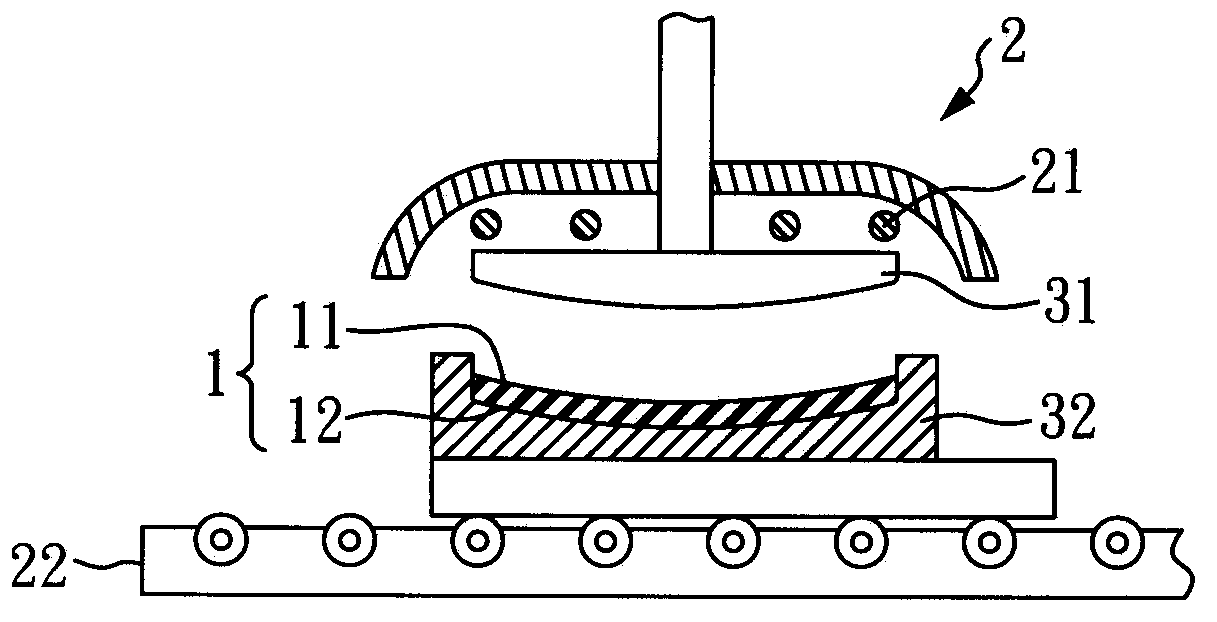

[0028] See Figure 1A to Figure 1C , Is the production flow chart of the three-dimensional glass of the first embodiment of the present invention.

[0029] First, like Figure 1A As shown, a first mold core 31, a second mold core 32 and a glass substrate 1 are provided in the cavity of a heating furnace 2 having a heater 21 and a conveyor belt 22, and the glass substrate 1 has A first molding surface 11 and a second molding surface 12 opposite to the first molding surface 11; the glass substrate 1 is set above the second mold core 32, and the second mold core 32 can be moved to by the conveyor 22 Corresponds to the position of the first mold core 31. In addition, the second mold core 32 has a concave structure, and the first mold core 31 has a convex structure, and it is connected to the heating furnace 2 by a connecting handle (not shown), and is vertically arranged in the furnace cavity of the heating furnace 2.

[0030] Then, like Figure 1B As shown, the cavity 2 of the heatin...

Embodiment 2

[0035] See image 3 , Is a schematic diagram of the production of three-dimensional glass in the second embodiment of the present invention. by image 3 As shown, this embodiment is a two-stage heating. A preheating furnace 5 and a forming furnace 6 are provided on a conveyor belt 8. First, a second mold core 72 and a glass substrate 4 are provided, and the glass substrate 4 It has a first molding surface 41 and a second molding surface 42 opposite to the first molding surface 41; the glass substrate 41 is placed above the second mold core 72, and the second mold core 72 can be moved by the conveyor belt 8 To the required location. In addition, the second mold core 72 has a concave structure.

[0036] In this embodiment, the furnace cavity of the preheating furnace 5 includes a heater 51 and a ventilation / exhaust pipe 52; in addition, the heater 51 of the preheating furnace 5 is a resistance-type wire heater, which allows the glass substrate 4 to perform The temperature is rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com