Deacidification and dehydration method of 3-chloropropene

A chloropropene and deacidification technology, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of acid and water content that cannot fully meet the high quality requirements of 3-chloropropene, and achieve physical and chemical Stable in nature, easy to regenerate, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

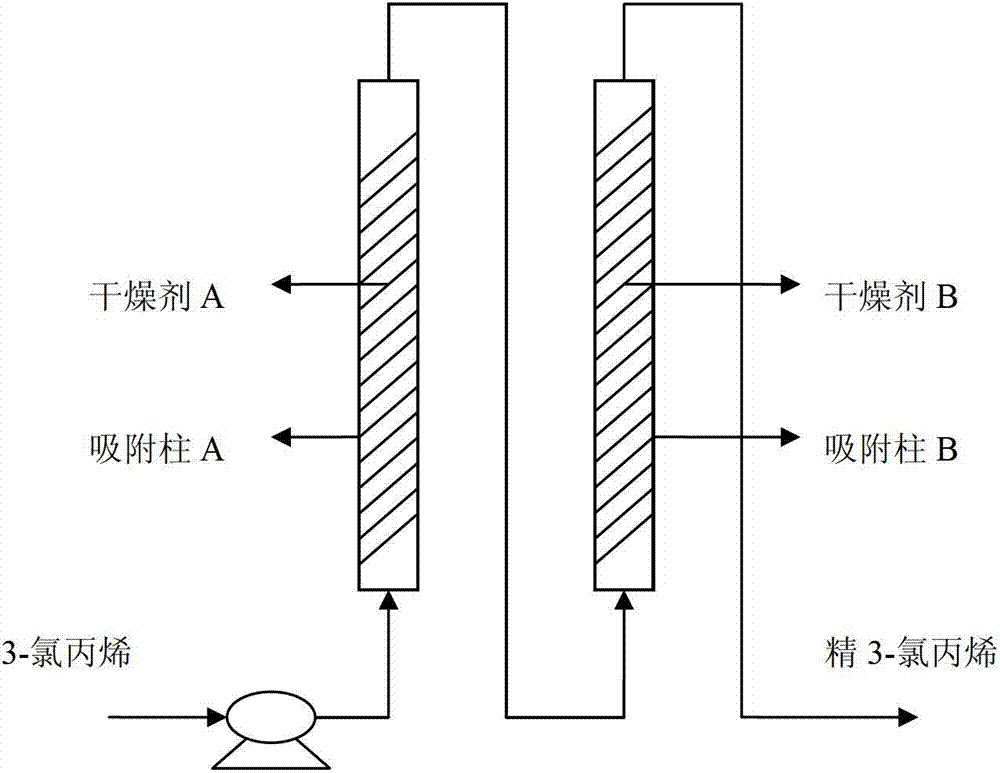

[0017] Put 35g of soda lime and 28g of silica gel into adsorption column A and adsorption column B respectively, connect them with the connecting pipe of the peristaltic pump, and evenly transport 6500g of crude 3-chloropropene through the adsorption column A and adsorption column B with the peristaltic pump , control the flow rate to 9.6g / min, and obtain refined 3-chloropropene after the treatment is completed. The acid content and water content of 3-chloropropene and refined 3-chloropropene were tested respectively, and the analysis results are shown in Table 1.

Embodiment 2

[0019] Put 30g of sodium sulfate and 38g of montmorillonite into the adsorption column A and adsorption column B respectively, connect them with the connecting pipe of the peristaltic pump, and evenly transport 9300g of 3-chloropropene through the adsorption column A and the adsorption column with the peristaltic pump B, control the flow rate to 7.5g / min, and obtain refined 3-chloropropene after the treatment is completed. The acid content and water content of 3-chloropropene and refined 3-chloropropene were tested respectively, and the analysis results are shown in Table 1.

Embodiment 3

[0021] Put 29g of anhydrous copper sulfate and 40g of silica gel into adsorption column A and adsorption column B respectively, connect them with the connecting pipe of the peristaltic pump, and transport 7200g of 3-chloropropene evenly through the adsorption column A and the adsorption column with the peristaltic pump B, control the flow rate of 7.2g / min, and obtain refined 3-chloropropene after the treatment is completed. The acid content and water content of 3-chloropropene and refined 3-chloropropene were tested respectively, and the analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com