A kind of composite bactericidal microsphere and its preparation method and application

A technology of microspheres and chlorine spheres, applied in the field of sterilization, can solve problems such as residual water bodies of soluble fungicides, and achieve the effects of realizing batch production and automatic control, reducing environmental pollution and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

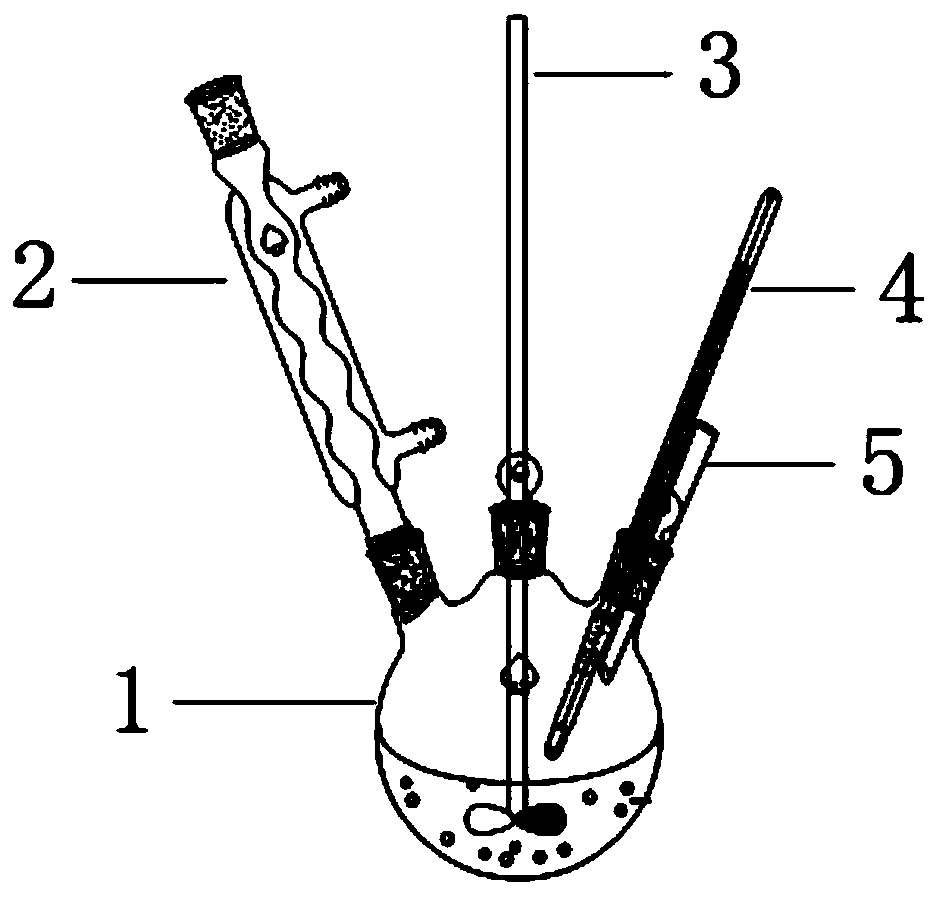

[0032] Measure 40 mL of reaction solvent into a three-necked flask with a volume of 100 mL, and add 60.0 mg of precursor (chlorine balls) to soak overnight. After the matrix is fully swollen, add a certain molar ratio of 5-mercapto-1-methyltetrazole and catalyst metal sodium into the three-necked flask, stir and react at a certain temperature, and pass nitrogen protection throughout the reaction. After reacting for 12 hours, filter out the microspheres in the three-neck flask, and then soak and wash them with the reaction solvent until the washing liquid is colorless or there is no obvious attachment on the surface of the microspheres. After washing with distilled water, soak them in NaOH aqueous solution, wash them with water, and then use After repeated washing with absolute ethanol, acetone, and ether several times, the filtered microspheres were vacuum-dried at 50°C for later use.

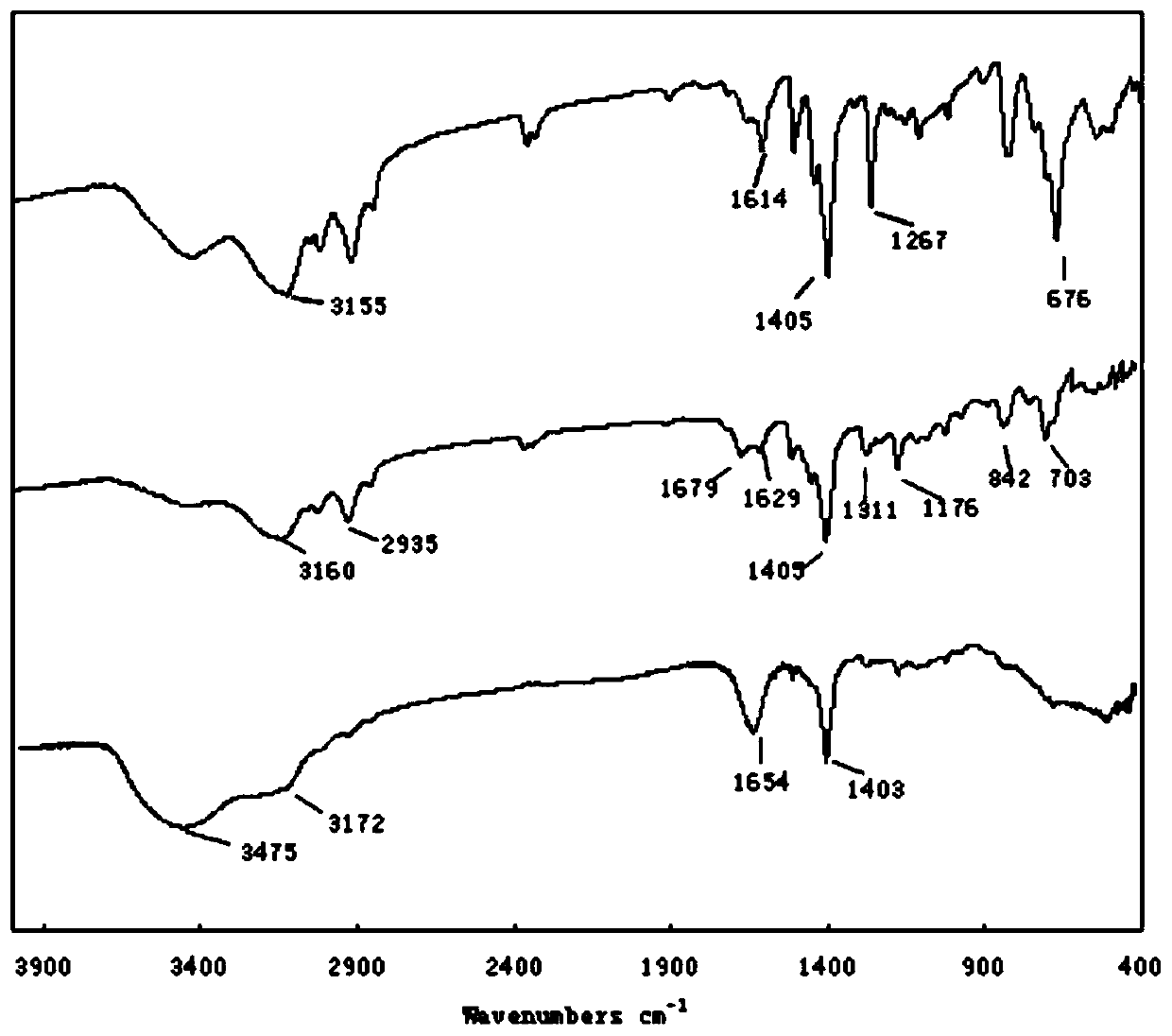

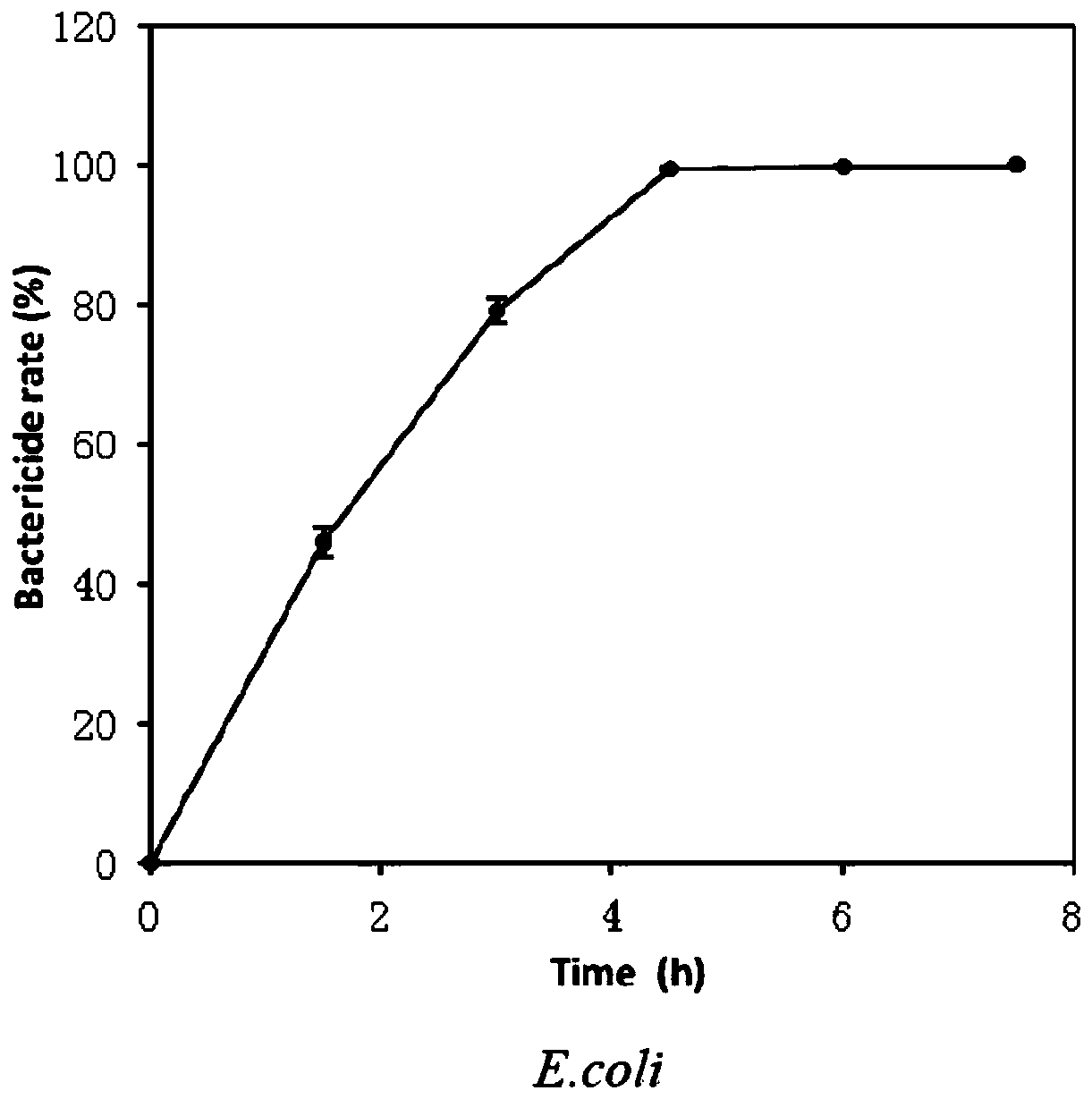

[0033] The present invention has carried out structural characterization to the synthesiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com