Steel for low-yield-ratio structure with yield strength larger than or equal to 690MPa and production method of steel

A technology of yield strength and low yield strength ratio is applied in the field of low yield strength ratio structural steel and its production, which can solve the problems of low strength level, unfavorable promotion and production, and no seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

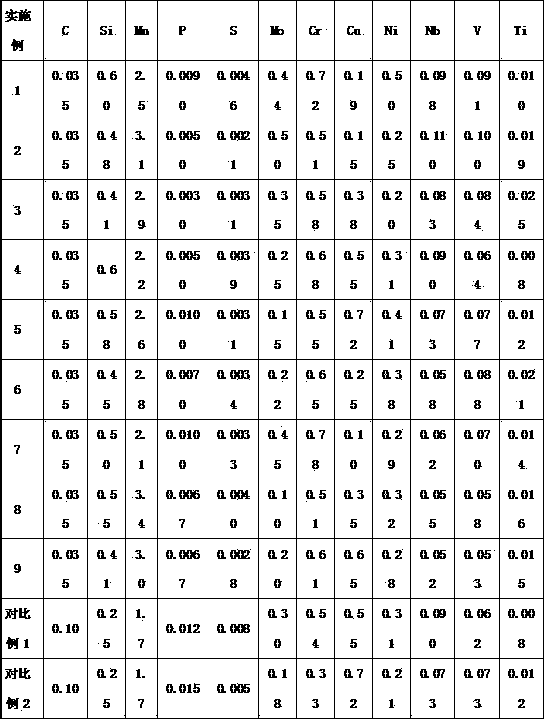

Embodiment

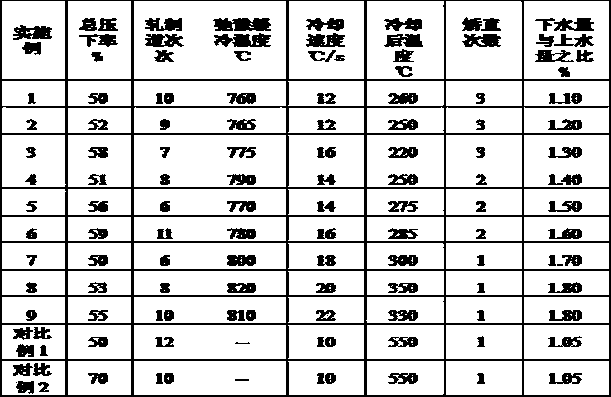

[0057] Examples are produced according to the following steps:

[0058] 1) Smelting and continuous casting into billets;

[0059] 2) Heating and keeping the casting blank, the heating temperature is controlled at 1240~1300°C, the heating rate is controlled at 6~9°C / s; the temperature is kept at 1160~1220°C for 40~50min;

[0060] 3) Carry out rough rolling: first cross rolling and then longitudinal rolling, the width ratio is controlled at 1.2~1.8; the starting rolling temperature is controlled at 1100~1160°C, the total reduction rate is 70~80%, and the rough rolling end temperature is at 1000 ~1060℃;

[0061] 4) Finish rolling: control the final rolling temperature at 800~880℃, the total reduction rate is 50~60%, and the rolling pass is 6~10;

[0062] 5) Cooling: first relax and cool to a temperature of 760~820°C, and then cool at a cooling rate of 12~22°C / s

[0063] Cool to 200~350°C, and finally air cool to room temperature;

[0064] 6) Straightening: After the steel plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com