Sponge bismuth powder displacement and deposition method under action of micro-currents

A bismuth sponge and micro-current technology, which is applied in the field of hydrometallurgy, can solve the problems of accelerating the replacement process and low-grade bismuth powder, and achieve the effects of promoting the replacement process, promoting pitting corrosion, and increasing the replacement specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

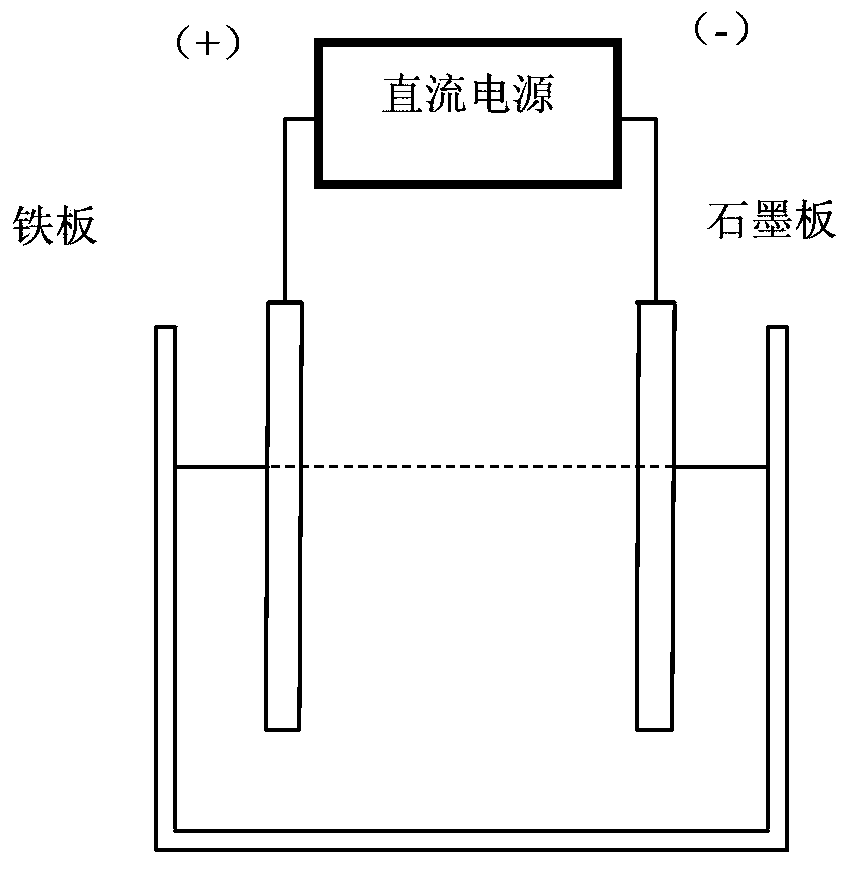

[0033] 1. Using the purification solution after bismuth leaching in a factory as raw material, its chemical composition (g / L) is: Bi 3+ 10.5, Sb 3+ 1.5, Pb 2+ 0.1, Cu 2+ 0.6,As 3+ 0.1, Ag + 0.02; pH=0.2; take 150mL of the material solution and place it in a 300mL reaction tank. The iron plate is 30mm long, 5mm wide, and 1mm thick; the graphite plate is 30mm long, 2.5mm wide, and 2mm thick. rust.

[0034] 2. Put the reaction tank into a 20°C water bath, connect the iron plate to the positive pole of the DC power supply, and connect the graphite plate to the negative pole of the DC power supply.

[0035] 3. Adjust the current density on the iron plate to 0.1×10 -3 A / cm 2 , the distance between the iron plate and the graphite plate is 1cm, the potential difference between the iron plate and the graphite plate is 0.2v, the magnetic stirring rate is 120r / min, the replacement time is 0.5h, the replacement rate reaches 90.6%, and the grade of the obtained bismuth powder is 90....

Embodiment 2

[0037] 1. Using the purification solution after bismuth leaching in a factory as raw material, its chemical composition (g / L) is: Bi 3+ 45, Sb 3+ 1.67, Pb 2+ 0.63, Cu 2+ 1.36,As 3+ 0.067, Ag + 0.006; pH=0.8; take 300mL of the stock solution and put it in a 500mL reaction tank to prepare an iron plate with a length of 50mm, a width of 20mm, and a thickness of 2mm;

[0038] 2. Put the reaction tank into a 40°C water bath, connect the iron plate to the positive pole of the DC power supply, and connect the graphite plate to the negative pole of the DC power supply.

[0039] 3. Adjust the current density on the iron plate to 1.0×10 -3 A / cm 2 , the distance between the iron plate and the graphite plate is 2cm, the potential difference between the iron plate and the graphite plate is 0.1v, the magnetic stirring rate is 100r / min, the replacement time is 1h, the replacement rate reaches 95%, and the grade of the obtained bismuth powder is 91.8%. Wherein the content of lead is le...

Embodiment 3

[0041] 1. Using the preliminary purification solution after bismuth leaching in a factory as raw material, its chemical composition (g / L) is: Bi 3+ 59.6, Sb 3+ 8.5, Pb 2+ 3.8, Cu 2+ 3.54, As 3+ 0.5, Ag + 0.05; pH=1.0 Take 4500mL of the stock solution and place it in a 5000mL reaction tank to prepare an iron plate with a length of 180mm, a width of 160mm, and a thickness of 2mm.

[0042] 2. Put the reaction tank into a 60°C water bath, connect the iron plate to the positive pole of the DC power supply, and connect the graphite to the negative pole of the DC power supply.

[0043]3. Adjust the current density on the iron plate to 10×10 -3 A / cm 2 , the distance between the iron plate and the graphite plate is 5cm, the potential difference between the iron plate and the graphite plate is 0.15v, the mechanical stirring rate is 150r / min, the replacement time is 2.5h, the replacement rate reaches 91.4%, and the grade of the obtained bismuth powder is 93.1%. , wherein the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com