Method and engine for operating a large crosshead reciprocating piston internal combustion engine

An internal combustion engine, reciprocating piston technology, applied in the direction of internal combustion piston engine, combustion engine, engine components, etc., can solve the problem of low NOx effect, and achieve the effect of simple structure, long service life, and less thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

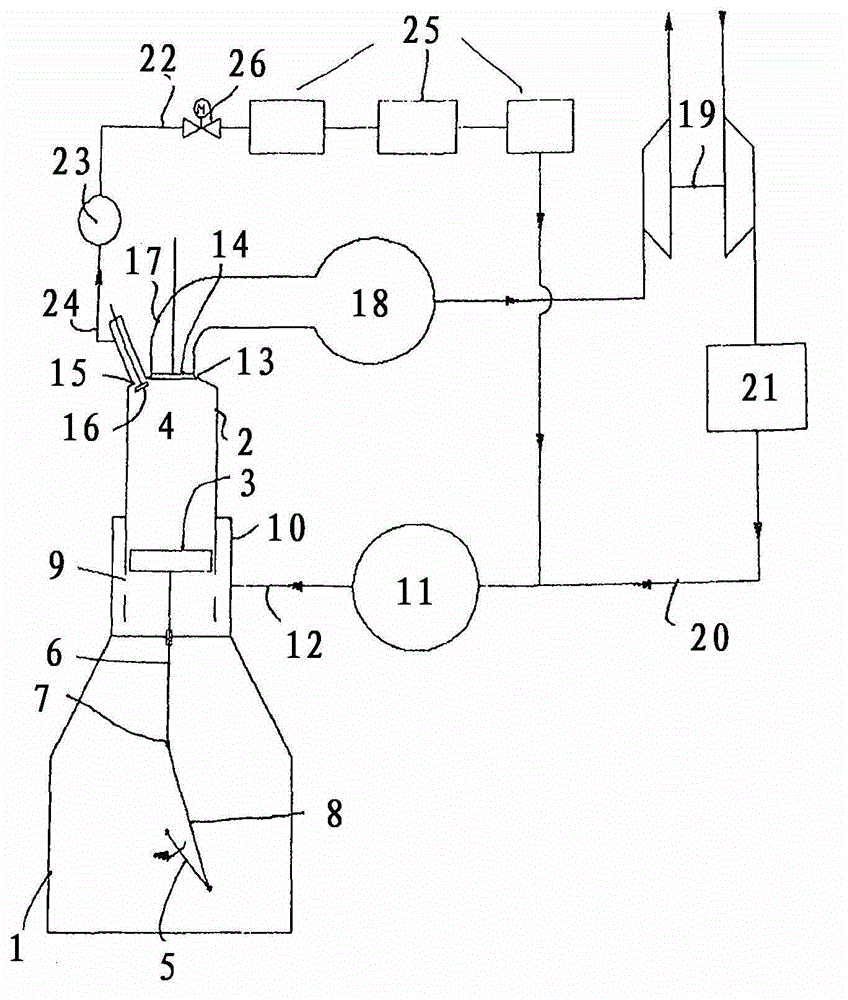

[0012] The main field of use of the invention is the field of large crosshead piston internal combustion engines, typically implemented as once-through scavenged two-stroke diesel and / or gas engines such as for propelling marine objects and / or operating power stations and the like.

[0013] figure 1 The engine shown in includes a crankcase 1 on which at least one cylinder 2 (usually a bank of cylinders 2 ) is arranged. Each cylinder 2 contains a reciprocating piston 3 as the moving boundary of a combustion chamber 4 . Piston 3 cooperates with crankshaft 5 located in crankcase 1 by means of piston rod 6 , crosshead 7 and connecting rod 8 . In the lower part of the cylinder 2 (at the second end) a scavenging port 9 is arranged as a slot. The scavenging port 9 can be passed through by the piston 3 and thus controlled by it. In the region of the scavenging gas opening 9 each cylinder 2 is surrounded by a scavenging gas channel 10 which is connected via a scavenging gas line 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com