A wear-resistant and anti-leakage slag cap with a combined core tube

A combined core tube and anti-leakage slag technology, which is applied in the direction of fuel burning in a molten state, combustion type, combustion method, etc., can solve the difficulty of welding and fixing the hood maintenance and replacement, the difficulty of changing and adjusting the structure of the hood, and the easy deformation of the thread to expand the hood Outer cover and other problems, to reduce the possibility of coking, low production cost, reduce the effect of air flow and momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

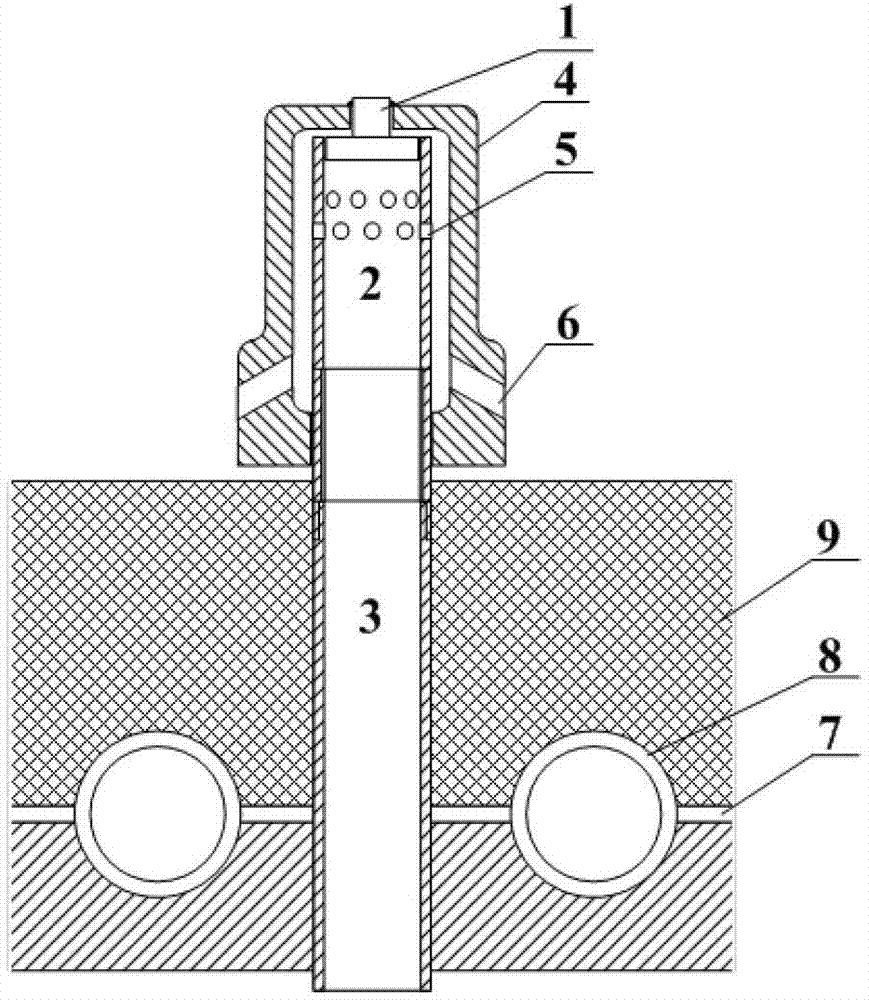

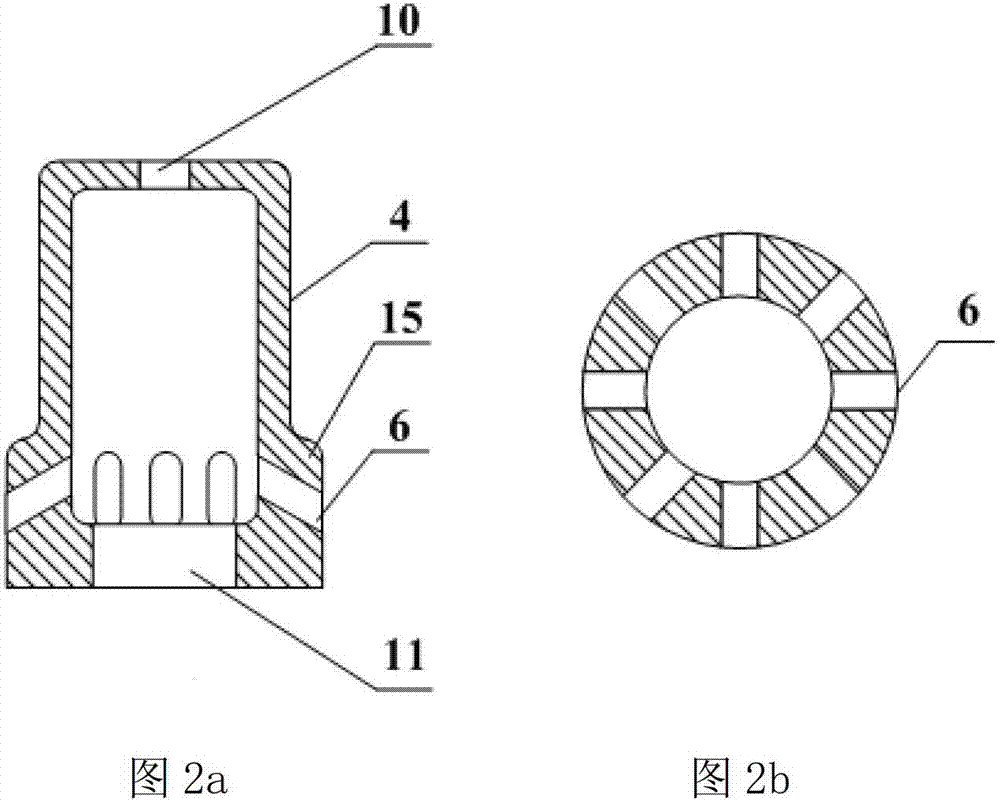

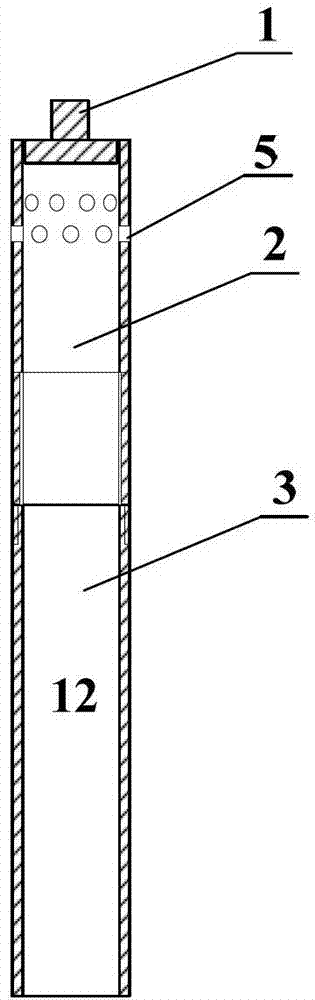

[0041] Such as figure 1 , figure 2 and image 3 As shown, the present invention has a wear-resistant and anti-leakage slag hood with a combined core tube, which includes a hood cover 4 with a top hole 10 on the top and a bottom hole 11 at the bottom, and a combination that passes through the hood cover 4 and is fixed thereto. The core tube 12, the combined core tube 12 is composed of a special-shaped plug 1, a guide core tube 2 and a fixed core tube 3 connected in sequence, and the combined core tube 12 passes through the top hole 10 of the wind cap cover 4 through the special-shaped plug 1 and the wind cap The outer cover 4 is fixed, and there is a flow gap between the outer wall of the combined core tube 12 and the inner wall of the hood cover 4. The combined core tube 12 passes through the bottom hole 11 of the hood cover 4 tightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com