Butterfly self-support type sensing cable

A self-supporting optical cable, sensing optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of thick outer sheath, low sensitivity, difficult to adapt to use, etc., to avoid uneven force, enhance sensitivity, and enhance resistance. stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

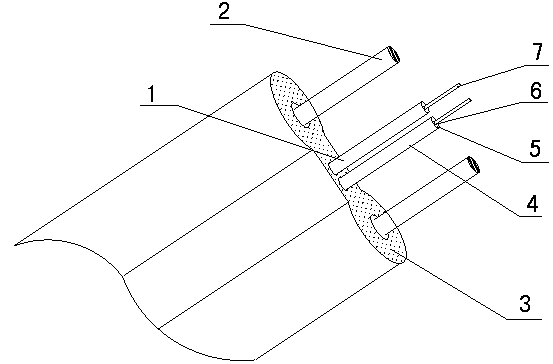

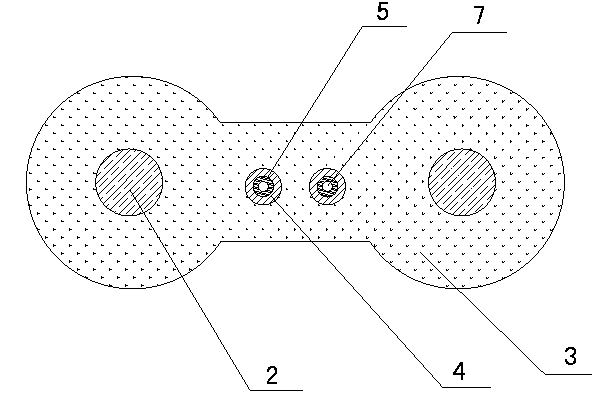

[0020] Such as figure 1 As shown, a butterfly-shaped self-supporting sensing optical cable, which includes an outer sheath 3, a strengthening member 2 and a sensing fiber 1, the sensing fiber 1 is sequentially composed of a PBT tube layer 4, a water-blocking material layer 5, The bonding layer 6 and the fiber core 7 are provided with a sensing fiber 1 and a strengthening member 2 inside the outer sheath 3, and the axes of the sensing fiber 1 and a pair of strengthening members 2 are located on the same horizontal plane.

[0021] The self-supporting sensing optical cable has a butterfly structure, which greatly reduces the installation difficulty of optical cable laying, and at the same time avoids uneven force on the sensing optical fiber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com