Pole core, lithium ion battery, manufacturing method for the pole core and manufacturing method for the lithium ion battery

A technology of lithium-ion battery and manufacturing method, which is applied in the field of electrochemistry, can solve the problems of increased thickness of lithium-ion battery, decreased portability of electronic equipment, and reduced user experience, etc., so as to be beneficial to battery life, not easy to fall off, and light in weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

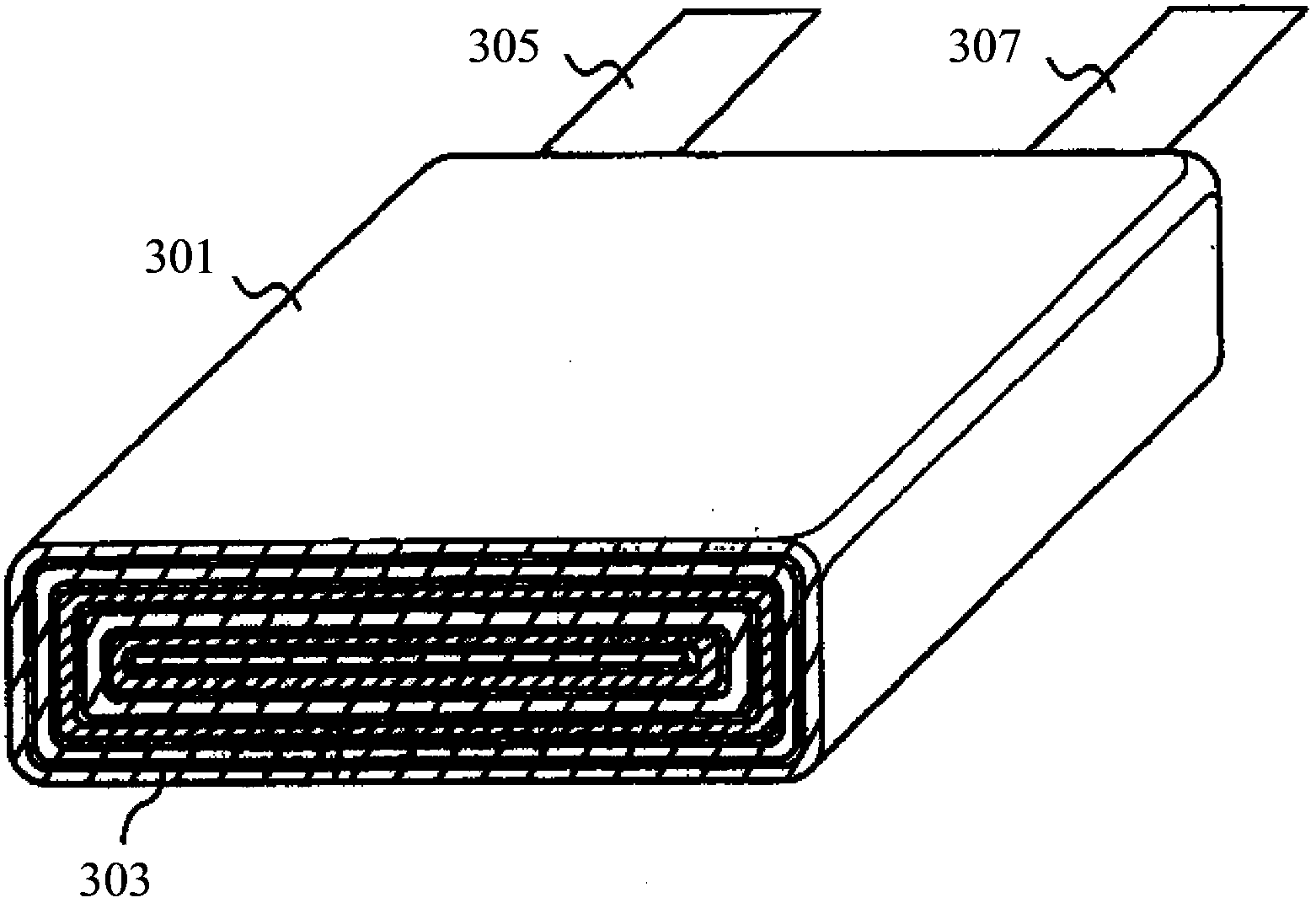

[0024] Various embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted.

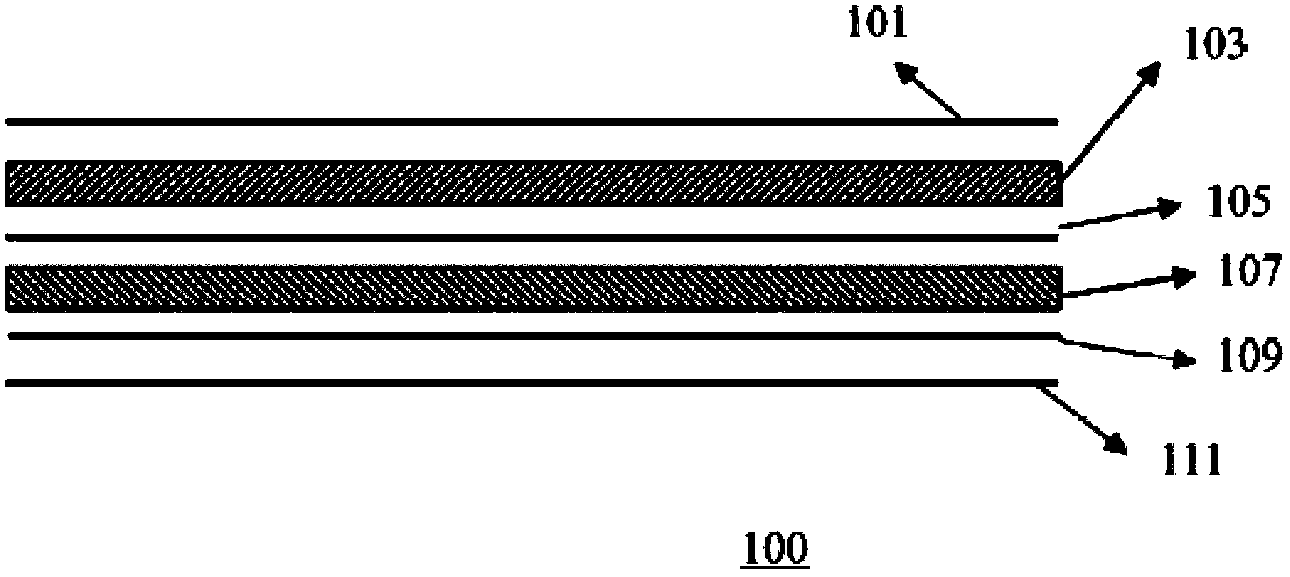

[0025] Below, will refer to figure 1 To describe the pole core of the lithium-ion battery in the prior art.

[0026] figure 1 The structure of a layer of pole core 100 in a lithium-ion battery in the prior art is illustrated.

[0027] As described in the background art section, in the prior art, increasing the capacity of a lithium-ion battery is contradictory to reducing its weight and reducing its thickness.

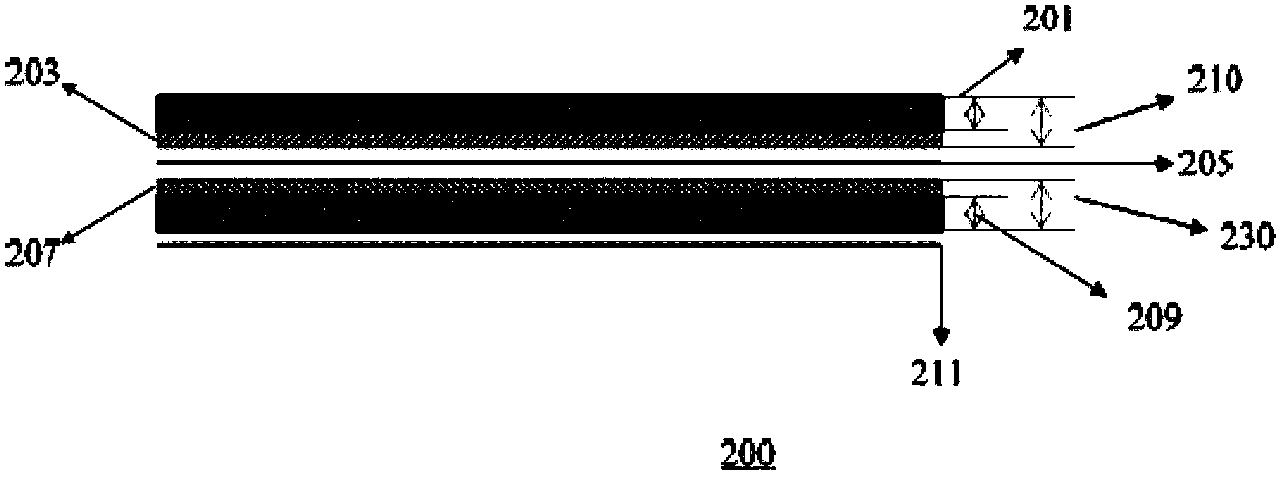

[0028] For example, take a lithium-ion battery with a capacity of 3700 milliamp hours (mAh) and a thickness of 3.3 millimeters (mm) as an example. Its interior includes battery pole cores that generally have at l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com