Novel high-efficiency thermionic power supply

A thermionic, high-temperature heat source technology, used in electrical components, generators/motors, generators that convert kinetic energy into electrical energy, etc., can solve the problems of complex power supply structure and operating conditions, small power generation capacity of a single power supply, and shrinking application fields. , to achieve the effect of inhibiting escape and transfer, accelerating escape and transfer, and improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

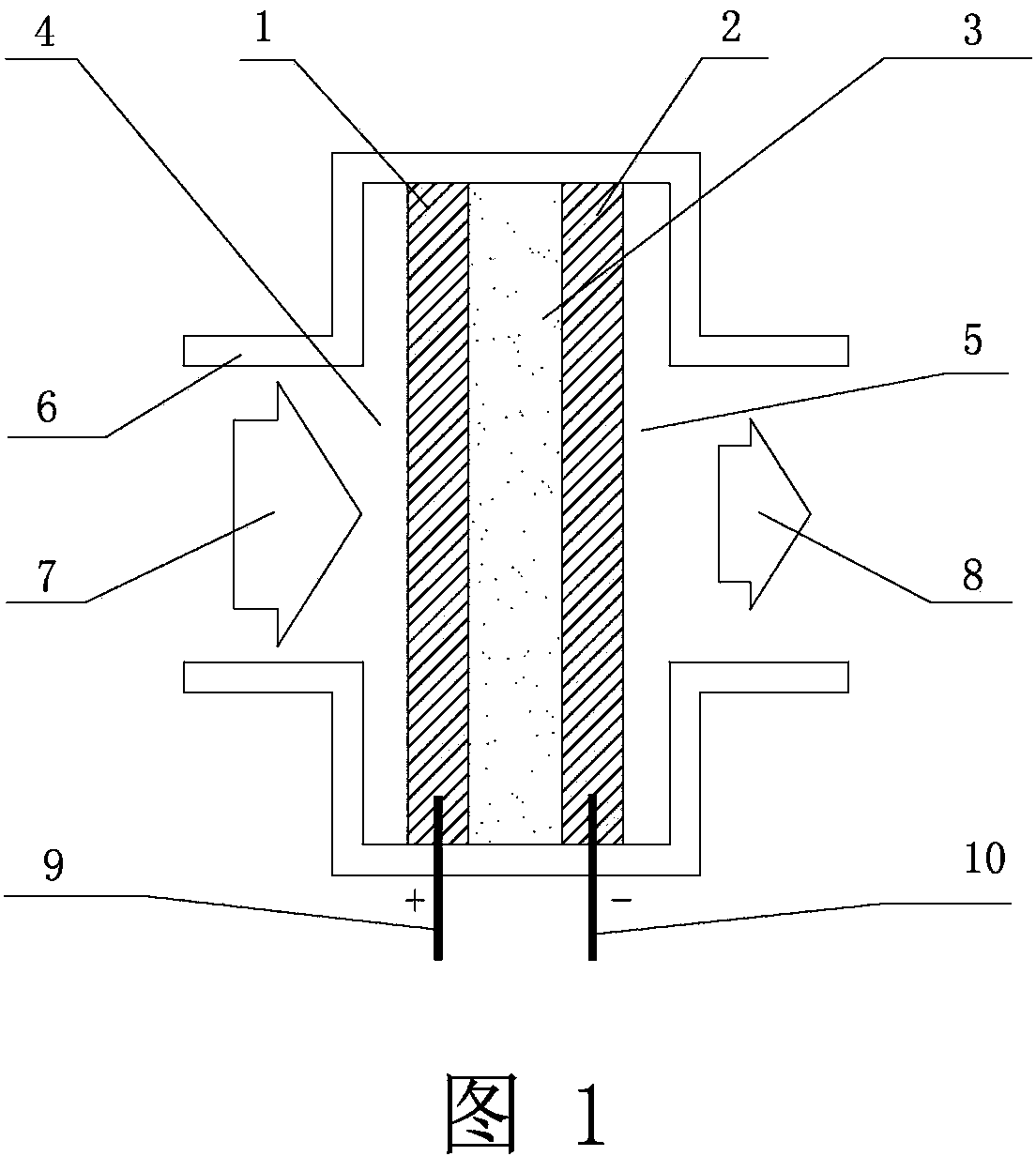

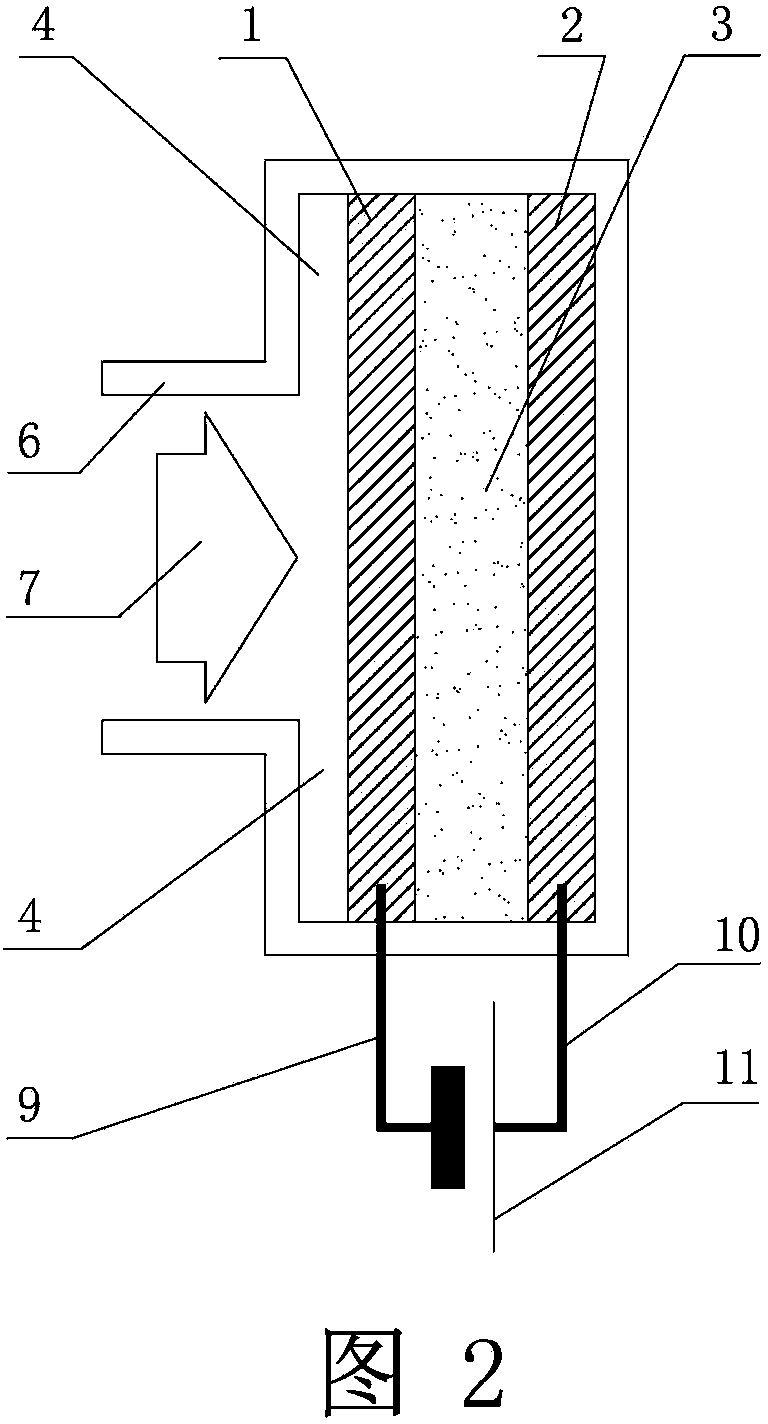

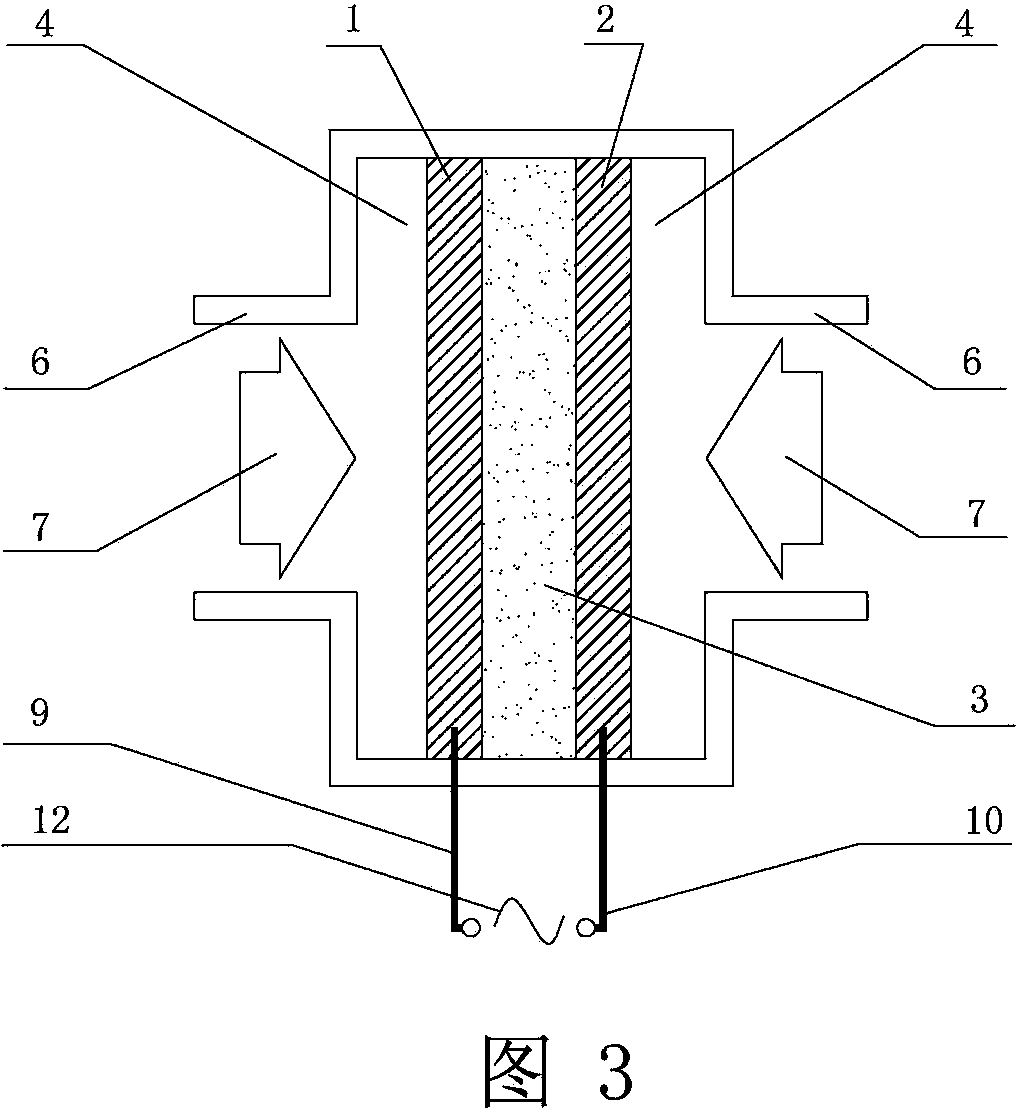

[0019] The present invention will be further described with reference to the accompanying drawings.

[0020] DC output scheme: the new high-efficiency thermionic power supply includes an emitter 1, a receiver 2, a high-temperature heat chamber 4 and a high-temperature heat source 7, and is characterized in that: the emitter 1 is made of a thermionic emission material whose melting point is higher than the temperature of the high-temperature heat source 7, The receiving electrode 2 is made of non-thermal electron emission material whose melting point is higher than the temperature of the high-temperature heat source 7, and the work function of the material of the emitting electrode 1 is less than or equal to the work function of the material of the receiving electrode 2; Inside, the heat-insulating shell 6 is closed, the emitter 1 and the receiver 2 are in the same high-temperature thermal cavity 4, the gap between the emitter 1 and the receiver 2 is between 0.01 and 2 mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com