Miniaturized integrated micro electo-mechanical systems (MEMS) optical sensor array

A micro-electromechanical sensor and sensing technology, applied in scientific instruments, instruments, microstructure technology, etc., can solve the problems of not being available on site, lack of parallel detection capability, expensive infrastructure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

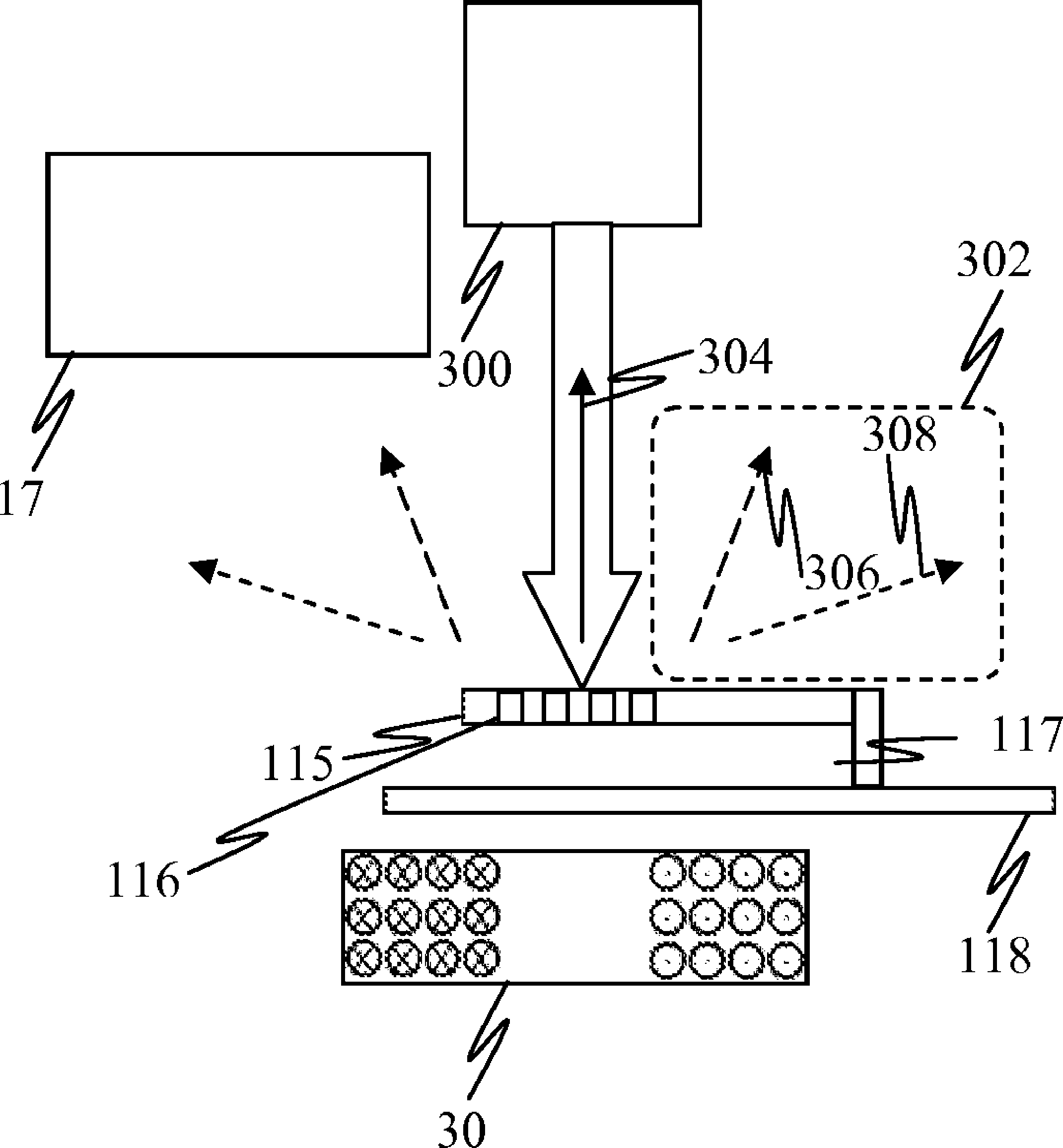

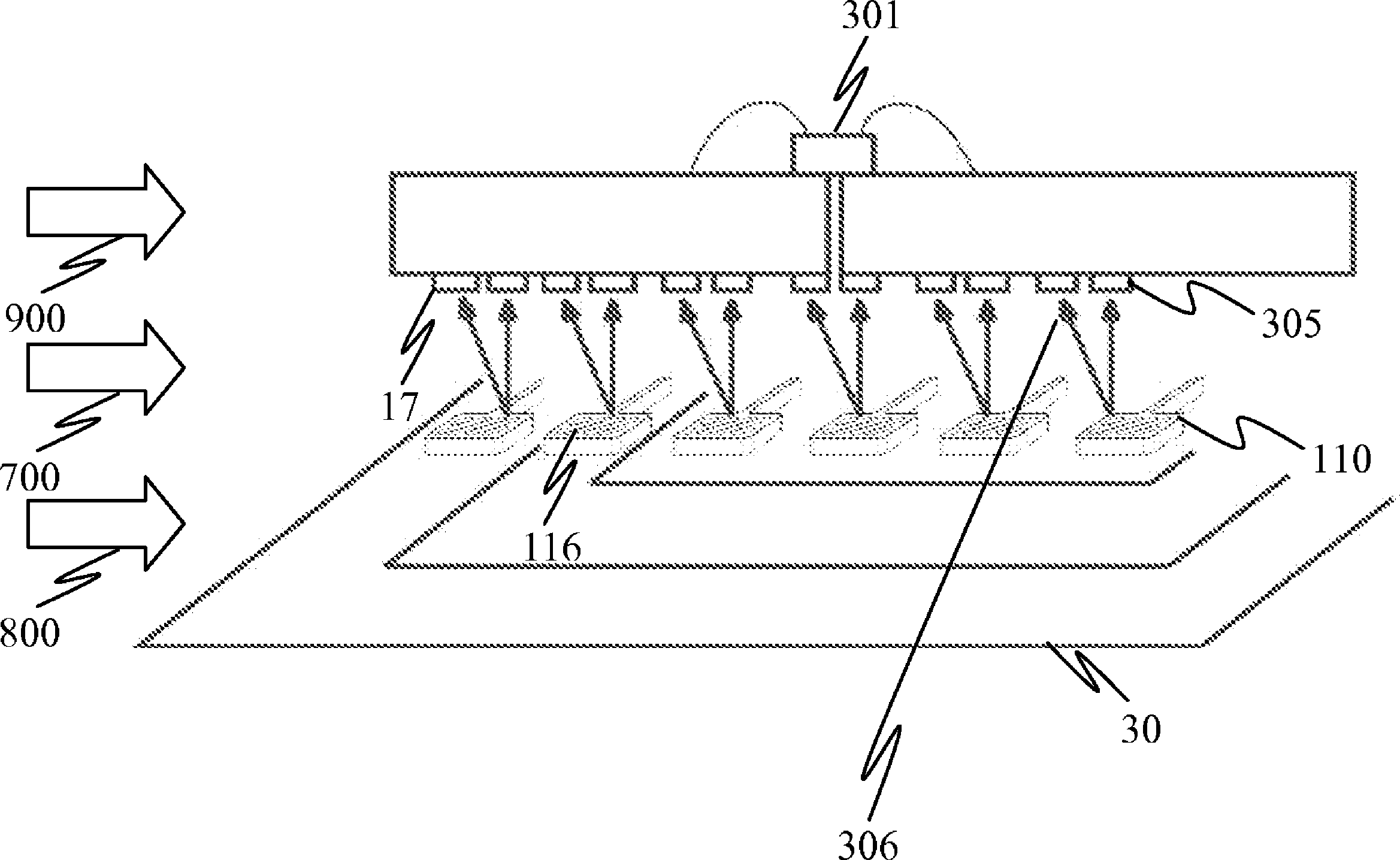

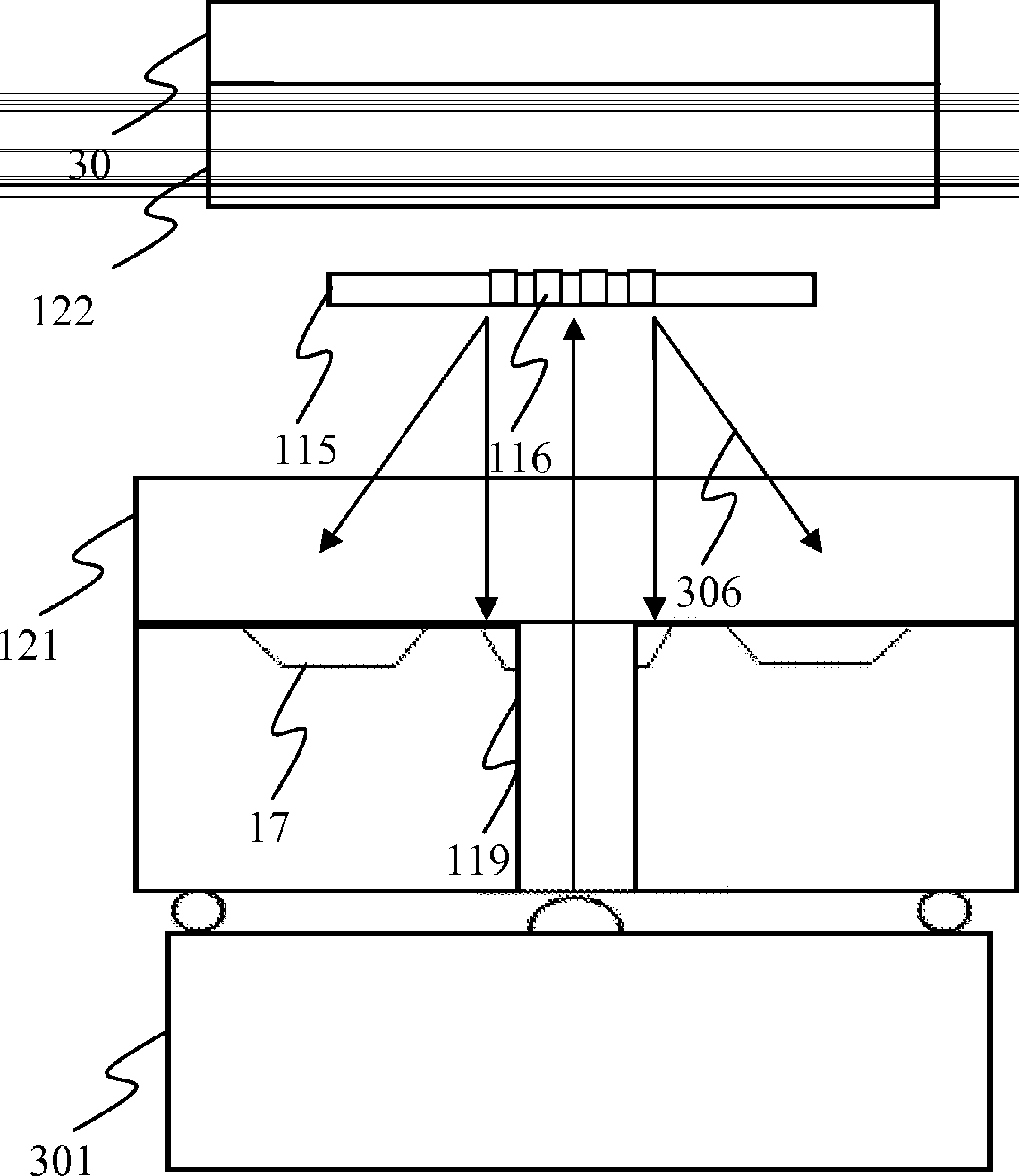

[0032] The key areas of the system in a preferred embodiment can be listed as follows: (1) Preferably includes the use of die-bonded laser diode arrays (1D VCSEL arrays), photodetectors, and CMOS using wafer thinning and through-Si via technology Detector chip with novel integrated optoelectronic chip on silicon for readout electronics; (2) MEMS sensor array 110 with micro / nano resonant cantilever with integrated grating structure, heating element, and remote electromagnetic actuator for disposable chip (also known as MEMS chips); (3) 3D integration of integrated optoelectronic chips and MEMS chips in the case of hybrid stacks; (4) MEMS cantilevers using a focus-fixed approach that addresses only one individual cantilever from the array Functionalization of recognition molecules (proteins, oligonucleotides, chemical assemblies) with different specificities; (5) Parallel sensor array operation (from 2 up to 64 parallel channels) for highly selective and accurate recognition of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com