Full-automatic continuous low sodium salt production method

A production method and low-sodium-salt technology, applied in applications, food preparation, food science, etc., can solve the problems of complicated production process, high labor intensity, and small production capacity, so as to ensure quality stability, reduce production cost, and ensure The effect of continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

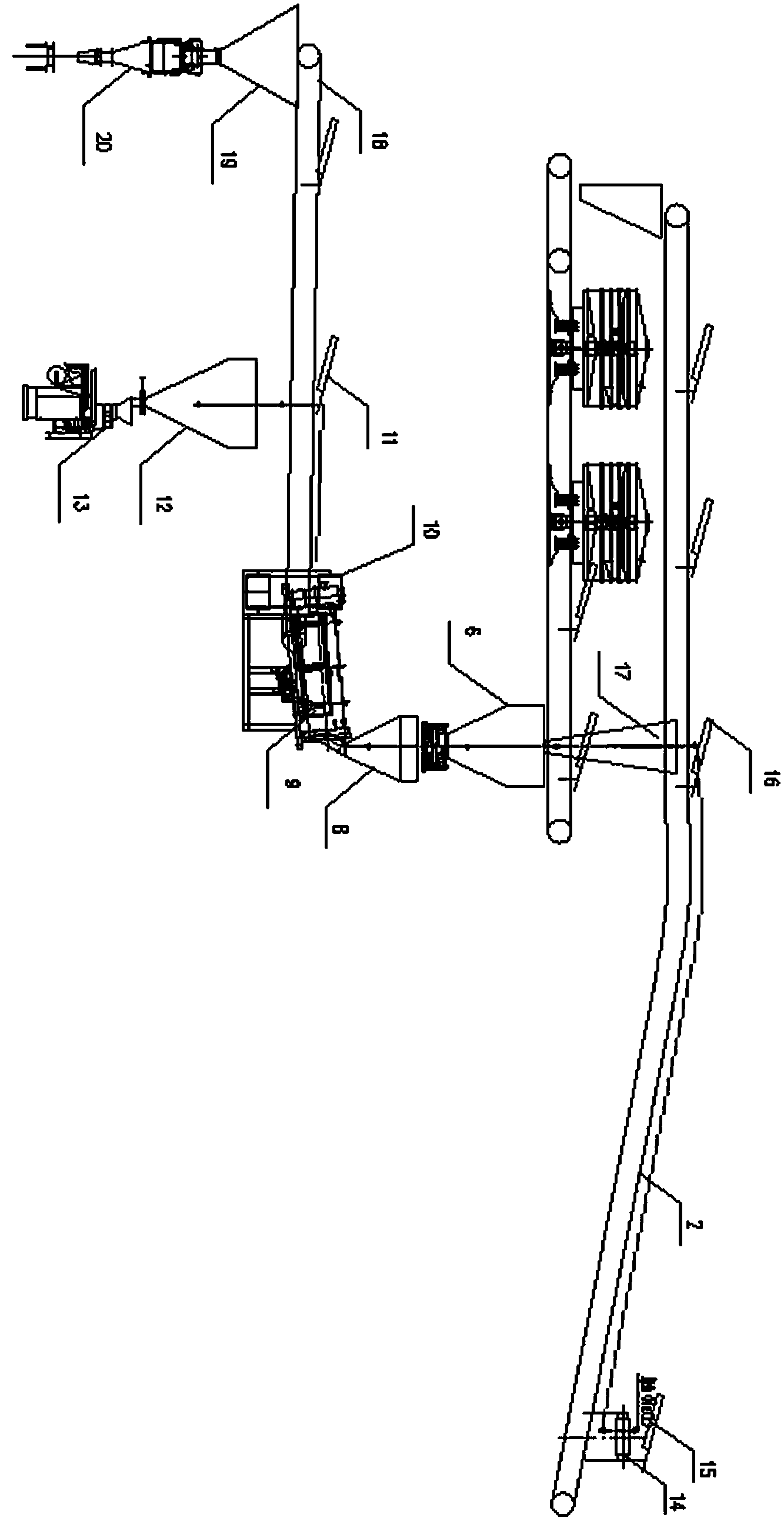

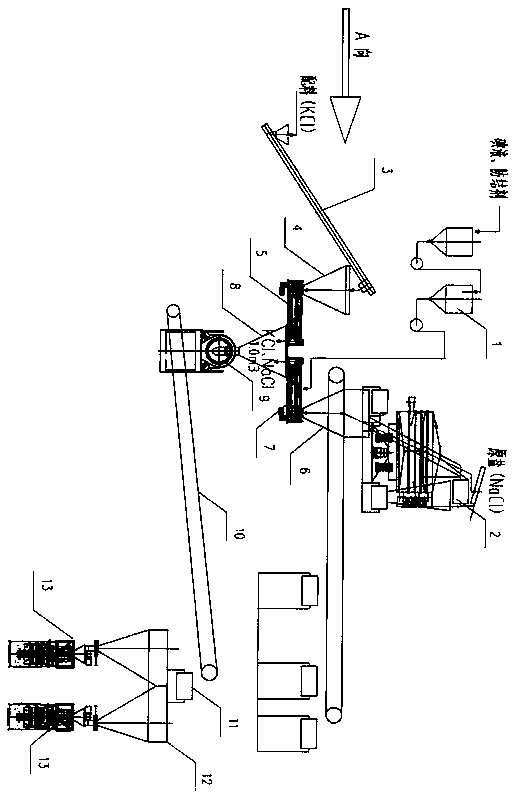

[0026] 1) Raw salt is separated from the raw salt belt conveyor 14 through the first electric unloader 15 to the first salt conveying belt conveyor 2, and then passed through the second electric unloader 16 to separate the salt, and then reaches the raw salt transition through the blanking chute 17 Feed bin 6 is metered by sodium chloride batching electronic belt scale 7, and sent into batching bin 8;

[0027] 2) The potassium chloride material is sent to the potassium chloride transition silo 4 through the potassium chloride conveying screw feeder 3, measured by the potassium chloride batching electronic belt scale 5, and sent to the batching silo 8;

[0028] 3) Add a certain amount of iodine liquid and anti-caking agent to the batching silo 8 through the iodine adding and anti-caking agent adding device 1;

[0029] 4) Send the material in the batching silo 8 into the mixer 9, and after fully mixing, it will be a semi-finished product;

[0030] 5) Through the second belt con...

Embodiment 2

[0032] 1) Raw salt is separated from the raw salt belt conveyor 14 through the first electric unloader 15 to the first salt conveying belt conveyor 2, and then passed through the second electric unloader 16 to separate the salt, and then reaches the raw salt transition through the blanking chute 17 Feed bin 6 is metered by sodium chloride batching electronic belt scale 7, and sent into batching bin 8;

[0033] 2) The potassium chloride material is sent to the potassium chloride transition silo 4 through the potassium chloride conveying screw feeder 3, measured by the potassium chloride batching electronic belt scale 5, and sent to the batching silo 8;

[0034] 3) Add a certain amount of iodine liquid and anti-caking agent to the batching silo 8 through the iodine adding and anti-caking agent adding device 1;

[0035] 4) Send the material in the batching silo 8 into the mixer 9, and after fully mixing, it will be a semi-finished product;

[0036] 5) Transfer to the tailing bin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap