Low-temperature activity treatment technology of flavor freshwater fish and treatment equipment of treatment technology

A treatment process and technology for freshwater fish, which is applied in the field of low-temperature active treatment process and treatment equipment for flavored freshwater fish, can solve problems such as backward processing technology, insecure quality, and insufficient nutrition, and achieve good economic benefits, improved production efficiency, The effect of improving flavor and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

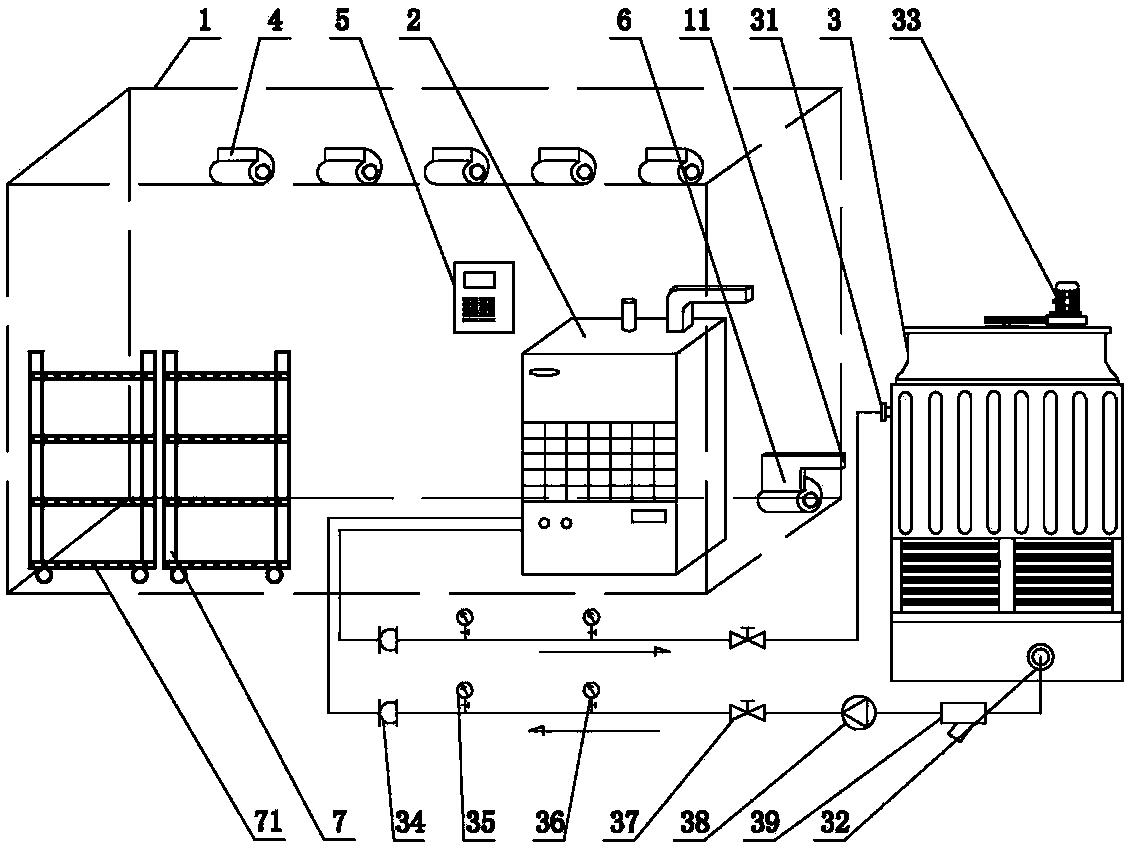

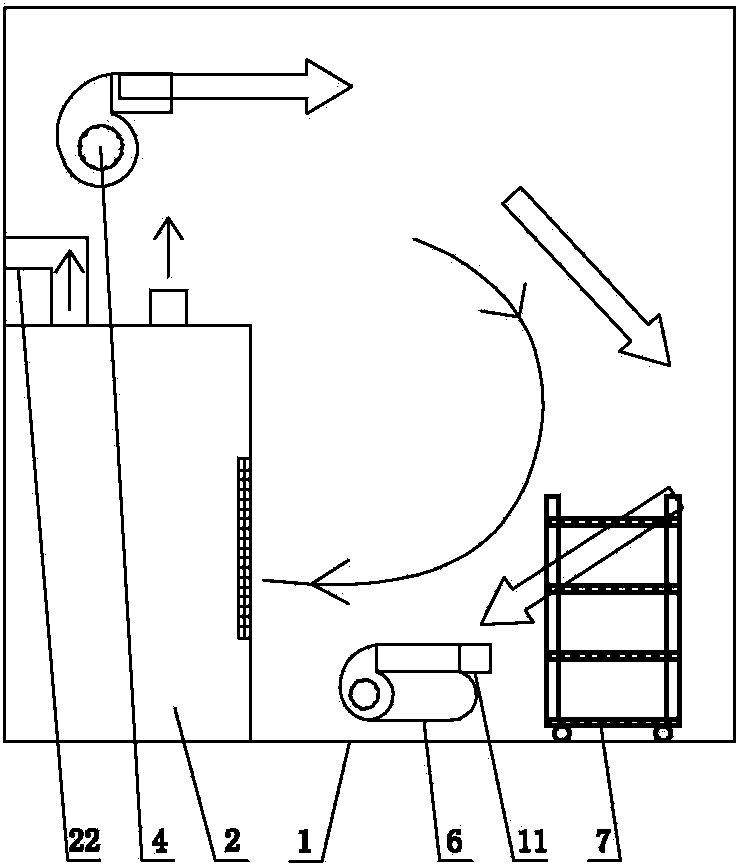

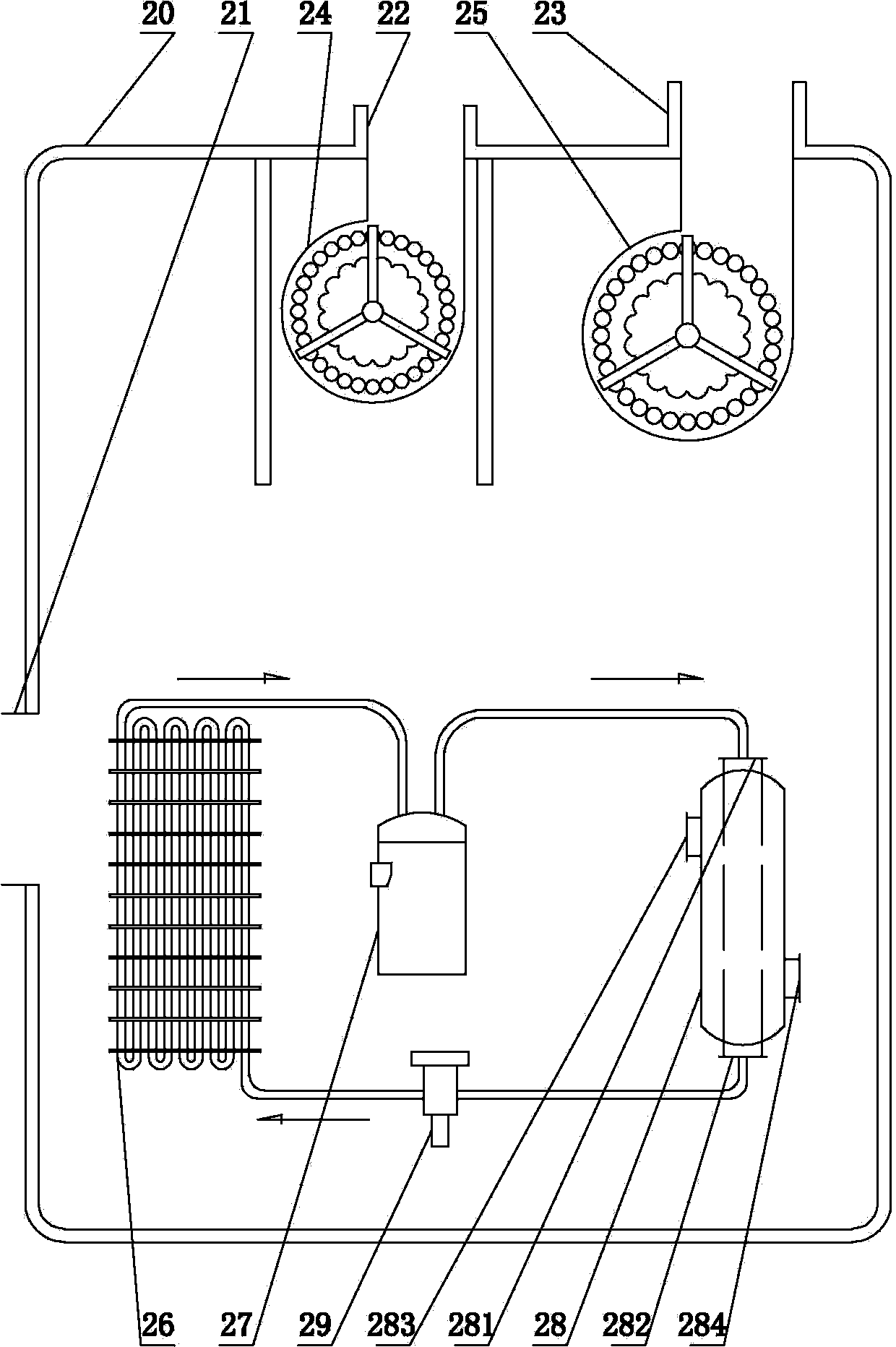

[0023] Embodiment 1: this local flavor freshwater fish low-temperature active treatment process comprises the following steps:

[0024] A. Select fresh grass carp or herring, each weighing about 1Kg. After slaughtering the fish, remove the scales and gills, cut the fish open from the back, remove the internal organs and scrape off the black membrane in the abdomen;

[0025] B. Wash the pretreated fish repeatedly to remove blood stains, and drain the rinsed fish until no water drips;

[0026] C. Put the fish into the blender, add 1 part of salt, 0.1 part of glutamyl transaminase, 0.2 part of nisin, and 0.7 part of konjac gum for every 100 parts of fish meat. set for 2 hours;

[0027] D. Put the fish on the air-drying trolley, send the air-drying trolley into the drying system to dehydrate the fish meat, the drying temperature is 5°C, and the drying time is 28 hours;

[0028] E. Send the dried fish into a vacuum packaging machine for packaging to obtain the finished product. ...

Embodiment 2

[0029] Embodiment 2: this local flavor freshwater fish low-temperature active treatment process comprises the following steps:

[0030] A. Select fresh grass carp or herring, each weighing about 1.25Kg. After slaughtering the fish, remove the scales and gills, cut the fish open from the back, remove the internal organs and scrape off the black membrane in the abdomen;

[0031] B. Wash the pretreated fish repeatedly to remove blood stains, and drain the rinsed fish until no water drips;

[0032] C. Put the fish into the blender, add 1 part of salt, 0.2 part of glutamyl transaminase, 0.3 part of nisin, and 0.85 part of konjac gum for every 100 parts of fish meat. Set for 2.5 hours;

[0033] D. Put the fish on the air-drying trolley, send the air-drying trolley into the drying system to dehydrate the fish meat, the drying temperature is 8°C, and the drying time is 29 hours;

[0034] E. Send the dried fish into a vacuum packaging machine for packaging to obtain the finished prod...

Embodiment 3

[0035] Embodiment 3: this local flavor freshwater fish low temperature active treatment process, comprises the following steps:

[0036] A. Select fresh grass carp or herring, each weighing about 1.5Kg. After slaughtering the fish, remove the scales and gills, cut the fish open from the back, remove the internal organs and scrape off the black film in the abdomen;

[0037] B. Wash the pretreated fish repeatedly to remove blood stains, and drain the rinsed fish until no water drips;

[0038] C. Put the fish into the blender, add 1 part of salt, 0.3 part of glutamyl transaminase, 0.4 part of nisin, and 1 part of konjac gum for every 100 parts of fish meat. set for 3 hours;

[0039] D. Put the fish on the air-drying trolley, send the air-drying trolley into the drying system to dehydrate the fish, the drying temperature is 10°C, and the drying time is 30 hours;

[0040] E. Send the dried fish into a vacuum packaging machine for packaging to obtain the finished product.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com