Composite absorbent used for flue gas desulphurization

An absorbent and flue gas technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of easy purchase, small foaming, and high desulfurization rate

Active Publication Date: 2013-12-11

JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

We absorb SO in the membrane 2 A lot of experimental research work has been done on composite absorbents, and novel and efficient composite absorbents have been proposed, which are currently used in flue gas purification of SO 2 There is no use and report in the field

Method used

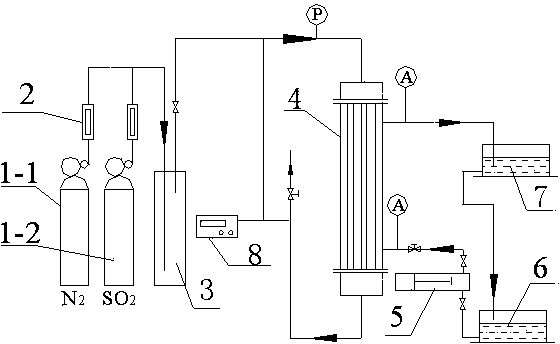

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of liquid-gas separation, especially to the field of flue gas desulphurization, specifically to a composite absorbent used for flue gas desulphurization. The objective of the invention is to provide a sulfur dioxide absorbent used for absorption of a membrane contactor. The composite absorbent used for flue gas desulphurization is composed of citrate and an aqueous solution of organic amine mixed according to a mol ratio of 1: 0.5-2. The composite absorbent has the advantages of good chemical stability, small foamability, small viscosity and a wide source, easy purchasing and a low price of raw materials. A desulphurization process using the composite absorbent has the advantages of a high mass transfer coefficient, no disturbance during flowing of gas and liquid, small mass transfer resistance, a high desulfurization rate, convenience in operation, great operational flexibility, no secondary pollution and stable running in the membrane contactor.

Description

technical field The invention relates to the field of liquid-gas separation, in particular to the field of flue gas desulfurization, and more specifically to a composite absorbent for flue gas desulfurization. Background technique SO in the flue gas of coal-fired power plants and metallurgical industries 2 It is one of the main pollutants in the atmosphere and the source of acid rain. With the increasing requirements of environmental protection on the emission of air pollutants, in the flue gas desulfurization purification, how to reasonably select the desulfurization process to achieve SO 2 Emissions in line with the national emission standards is a key issue for the healthy development of flue gas desulfurization in coal-fired power plants and metallurgical industries. Therefore, various high-performance SO 2 The development of absorbents is one of the research topics in this field. In recent years, composite absorbents have become a hot topic in the research and deve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/14

Inventor 陆建刚陆春婷陈悦张慧许正文

Owner JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com