Particle material classification sorting device

A technology for grading and screening granular materials, which is applied in the field of material grading and screening devices and granular material grading and screening devices. Work efficiency, simple structure, and the effect of improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

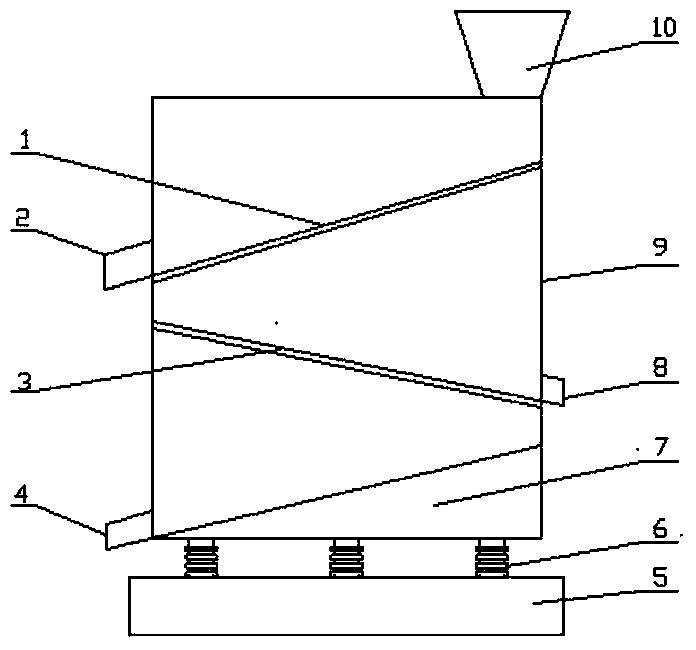

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the lower hopper 10 is welded to one end of the top of the screening box 9, which is beneficial to the screening of granular materials. The upper sieve plate 1 is installed obliquely on the upper part of the screening box 9, and the installation angle is about 30° from the horizontal plane to ensure that the materials are screened. The residence time on the plate is optimum. The bottom end of the upper sieve plate 1 is provided with a rectangular channel, that is, the large particle discharge port 2, to facilitate the flow of materials. The lower sieve plate 3 is also installed obliquely, but the direction of inclination is opposite to that of the upper sieve plate 1, and there must be a certain distance between the two sieve plates to ensure that the granular material falls from the upper sieve plate 1 to the lower sieve plate 3 and has a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com