A filling medium for extruding pipe-through parts and a manufacturing process of pipe-through parts

A technology of filling medium and manufacturing process, which is applied in the field of pipeline engineering and refrigeration pipe fittings, and can solve the problem of broken pipe wall, which requires lead removal, lead filling again, and lead removal again. The process steps of lead filling are complicated and the process flow is complicated and other issues, to achieve the effects of large-scale application, ease of industrial scale production, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 100g of calcium nitrate Ca(NO 3 ) 2 4H 2 O, 1800g sodium nitrate NaNO 3 Mix evenly with 100g of water;

[0052] Put the obtained mixture in a heating vessel and heat and melt it at 800°C until the mixture is completely melted to a liquid state, and then use an automatic filling machine to fill the molten mixture into 50 low-carbon tubes with an outer diameter of Φ10mm and a length of 80mm. In the steel pipe, after cooling, place the low-carbon steel pipe filled with the filling medium in a T-shaped die cavity with a cavity of Φ10mm for extrusion molding; then place the extruded pipe fittings in the above-mentioned In the mixture, the filling medium in the pipe fitting is melted by high temperature, and flows out of the pipe fitting after 5 minutes, completing the removal of the filling medium in the pipe fitting, and obtaining a T-shaped tee pipe fitting.

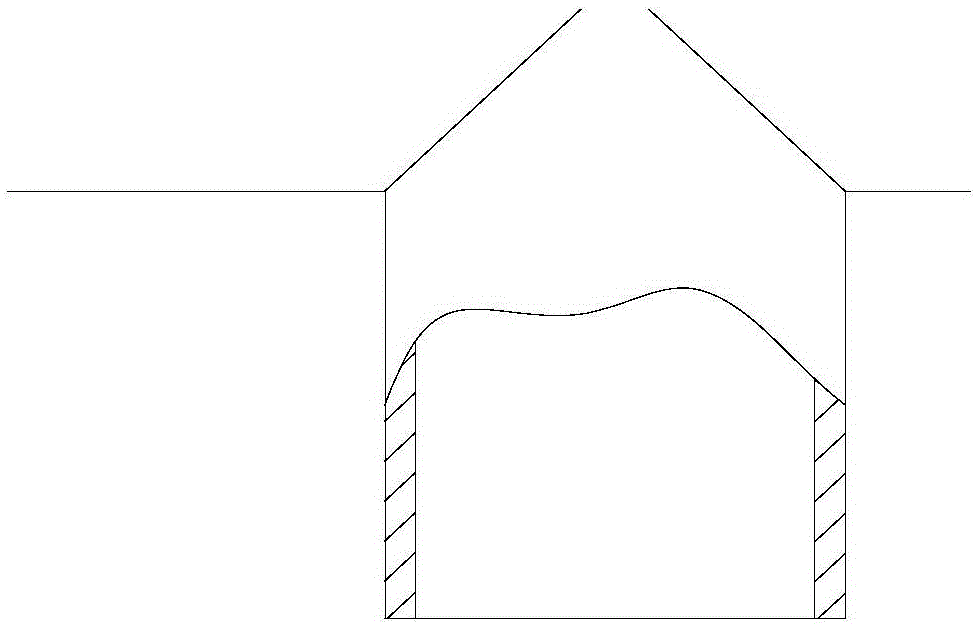

[0053] The structure of T-shaped three-way pipe fittings is as follows: figure 1 As shown, the T-shaped tee p...

Embodiment 2

[0055] 600gCa(NO 3 ) 2 4H 2 O, 2370g sodium nitrate and 30g water are evenly mixed;

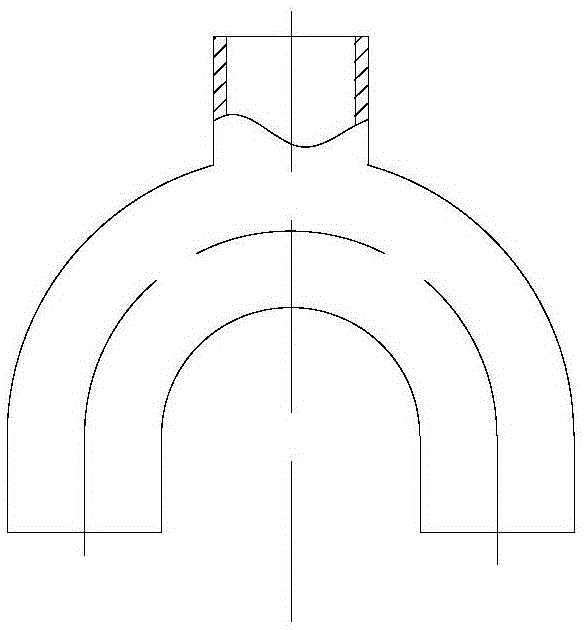

[0056] Put the obtained mixture in a heating vessel, heat and melt at 220°C until the mixture is completely melted to a liquid state, and use an automatic filling machine to fill the molten mixture into 100 pieces of aluminum with an outer diameter of Φ8mm and a length of 100mm After cooling, place the aluminum tube filled with filling medium in a Y-shaped tee mold with a cavity of Φ8mm for extrusion molding; then place the extruded pipe fittings in the above-mentioned In the mixture, the filling medium in the pipe-through part is melted by high temperature, and flows out from the pipe-through part after 5 minutes to complete the removal of the filling medium in the pipe-through part. In the process of removing the filling medium, the high temperature plays a role in the pipe-through part Tempering effect: Bending the empty pipe fittings after removing the filling medium on the empty pipe ...

Embodiment 3

[0059] 2000gCa(NO 3 ) 2 , 1600g sodium nitrate and 400g water are evenly mixed;

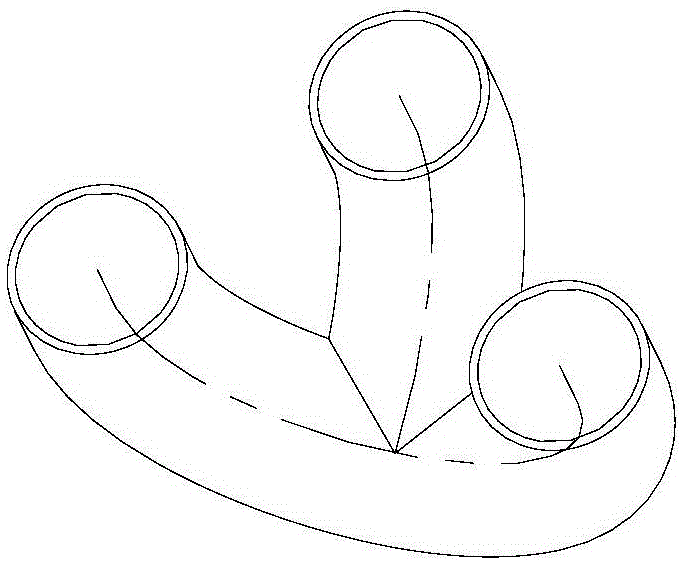

[0060] Put the obtained mixture in a heating vessel, heat and melt at 100°C until the mixture is completely melted to a liquid state, and use an automatic filling machine to fill the molten mixture into 150 tubes with an outer diameter of Φ9mm and a length of 90mm In the copper tube, after cooling, put the copper tube filled with the filling medium into a mold with a cavity of Φ9mm for extrusion molding; then place the extruded pipe fittings in the above-mentioned mixture after high temperature melting at 450°C, The filling medium in the pipe-through is melted by high temperature, and flows out of the pipe-through after 5 minutes to complete the removal of the filling medium in the pipe-through. In the process of removing the filling medium, the high temperature has a tempering effect on the pipe-through ; Bending the empty pipe fittings after removing the filling medium on the empty pipe bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com