Automatic flexible processing device and processing method for special-shaped bar

An automatic processing and flexible technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of unsuitable automatic clamping of special-shaped bars, difficulty in completing order tasks on time, difficulty in recruitment and management, etc. and management difficulties, high product quality stability, and the effect of improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

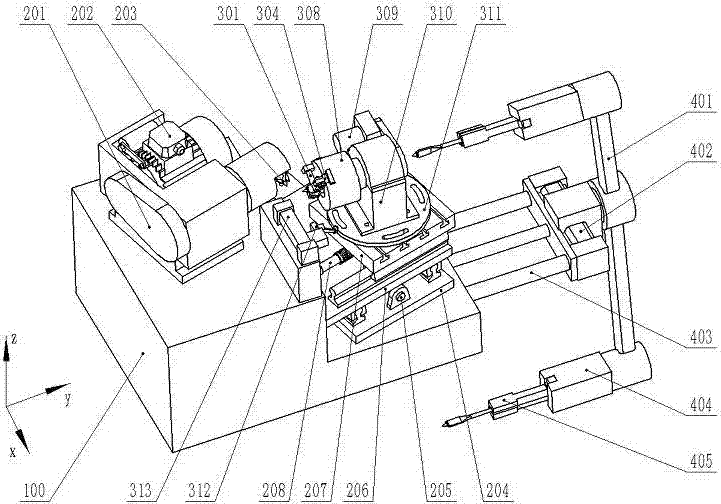

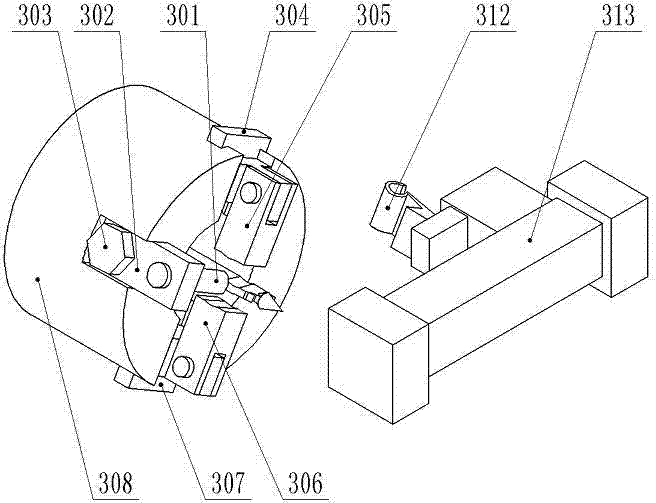

[0041] as attached figure 1 And attached figure 2 As shown, the present invention includes a base 100, an automatic loading and unloading module, a flexible clamping module and a servo feed cutting module; wherein:

[0042] 1) Automatic loading and unloading module: including a y-axis swing cylinder 401, a y-axis direction translation cylinder 402, two swing arms 403, two pairs of translation air grippers 404 and two pairs of hand grippers 405; the y-axis direction translation cylinder 402 along the The y-axis direction is fixedly installed inside the base 100, the y-axis swing cylinder 401 is fixed along the x-axis direction and the piston of the y-axis translation cylinder 402, and the swing arm 403 is connected with the output shaft of the y-axis swing cylinder 401 through a rotating pair. The translational air grippers 404 are respectively fixed on the outer ends of the two swing arms 403 along the y-axis direction, and the two pair of hand grippers 405 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com