Preparation method of highly polymerized polyvinyl chloride resin chain extender emulsion

A polyvinyl chloride resin with high degree of polymerization technology, applied in the field of copolymers of vinyl chloride, to achieve the effects of wide resin molecular weight distribution, increased processing performance and resilience, and regular particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The following examples can better illustrate the present invention:

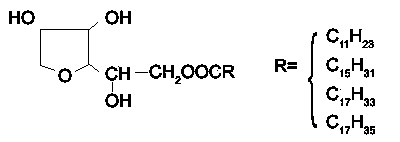

[0019] Span 80 and Tween 40 are used as emulsifier raw materials. The HLB value of Span 80 is 4.3, and the HLB value of Tween 40 is 15.6. The emulsifier HLB is compounded according to a certain mass percentage of c1 and c2. The value is W, then W=c1×HLB1+c2×HLB2. Use this relational formula to prepare composite emulsifiers with HLB values of 12.5±0.5 and 13±0.5 for the preparation of chain extender a emulsion of alkyl alcohol esters of acrylate and chain extender b emulsion of allyl esters . Under certain conditions, when the amount of emulsifier is 5% of the mass of chain extender a, the stirring time is 60min, and the stirring speed is 800r / min, an emulsion with a Zeta of 35mV chain extender a is prepared; when the amount of emulsifier is Under the conditions of 7% chain extender emulsion mass, 60 min stirring time, and 900 r / min stirring speed, the chain extender b emulsion with a Zeta of 33 mV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com