Nano film-embedded emulsion lubricant

A film emulsification and lubricant technology, applied in the field of lubricants, can solve the problems of large friction resistance, serious supporting pressure, and poor lubrication effect of drilling fluid in horizontal wells, so as to reduce relative friction resistance, improve structural effect, and good plugging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare the components in parts by weight, and prepare the low-fluorescence nano-ball embedded emulsified lubricant according to the following production steps:

[0027] (1) Mix compound emulsifier by weight

[0028] Non-ionic complex emulsifier: Span-80: Tween-80: tripolyglycerol monostearate ratio is 5:0.95:3,

[0029] Composite emulsifier: non-ionic composite emulsifier: the ratio of alkyl alcohol phosphate sodium salt is 4.5:1.

[0030] (2) Prepare raw materials

[0031] Modified paraffin 10g, composite emulsifier 3g, alkalinity regulator 0.5g, nanometer graphite powder 2g, water 84.5g.

[0032] (3) Preparation of emulsified lubricant

[0033] Add 84.5g of water to the reactor, heat up to 50°C, stir slowly at 400r / min, add 10g of paraffin and 3g of compound emulsifier into the reactor, heat up to 75°C while stirring, increase the stirring speed to 800r / min, and stir for 40min. Mix in the alkalinity regulator, continue to stir for 40 minutes, slowly stir to room ...

Embodiment 2

[0035] (1) Mix compound emulsifier by weight

[0036] Process is identical with embodiment 1.

[0037] (2) Prepare raw materials

[0038] Modified paraffin 20g, composite emulsifier 5g, alkalinity regulator 1g, nanometer graphite powder 1g, water 73g.

[0039] (3) Preparation of emulsified lubricant

[0040] Add 74g of water to the reaction kettle, raise the temperature to 50°C, stir slowly at 500r / min, add 20g of paraffin wax and 5g of compound emulsifier into the reaction kettle, raise the temperature to 80°C while stirring, increase the stirring speed to 1000r / min, stir for 40min, mix in Alkalinity regulator, continue to stir for 40 minutes, slowly stir to room temperature, mix 1g of nano-graphite powder, stir at 1000r / min at room temperature for 40 minutes, stop stirring, pack and discharge.

Embodiment 3

[0042] (1) Mix compound emulsifier by weight

[0043] Process is identical with embodiment 1.

[0044] (2) Prepare raw materials

[0045] Modified paraffin wax 30g, composite emulsifier 11g, alkalinity regulator 3g, nanometer graphite powder 0.5g, water 58.5g.

[0046] (3) Preparation of emulsified lubricant

[0047] Add 58.5g of water to the reactor, heat up to 50°C, stir slowly at 600r / min, add 30g of paraffin and 11g of compound emulsifier into the reactor, heat up to 90°C while stirring, increase the stirring speed to 1200r / min, and stir for 40min. Mix in the alkalinity regulator, continue to stir for 40 minutes, slowly stir to room temperature, mix in 0.5 g of nano-graphite powder, stir at 1000 r / min for 40 minutes at room temperature, stop stirring, pack and discharge.

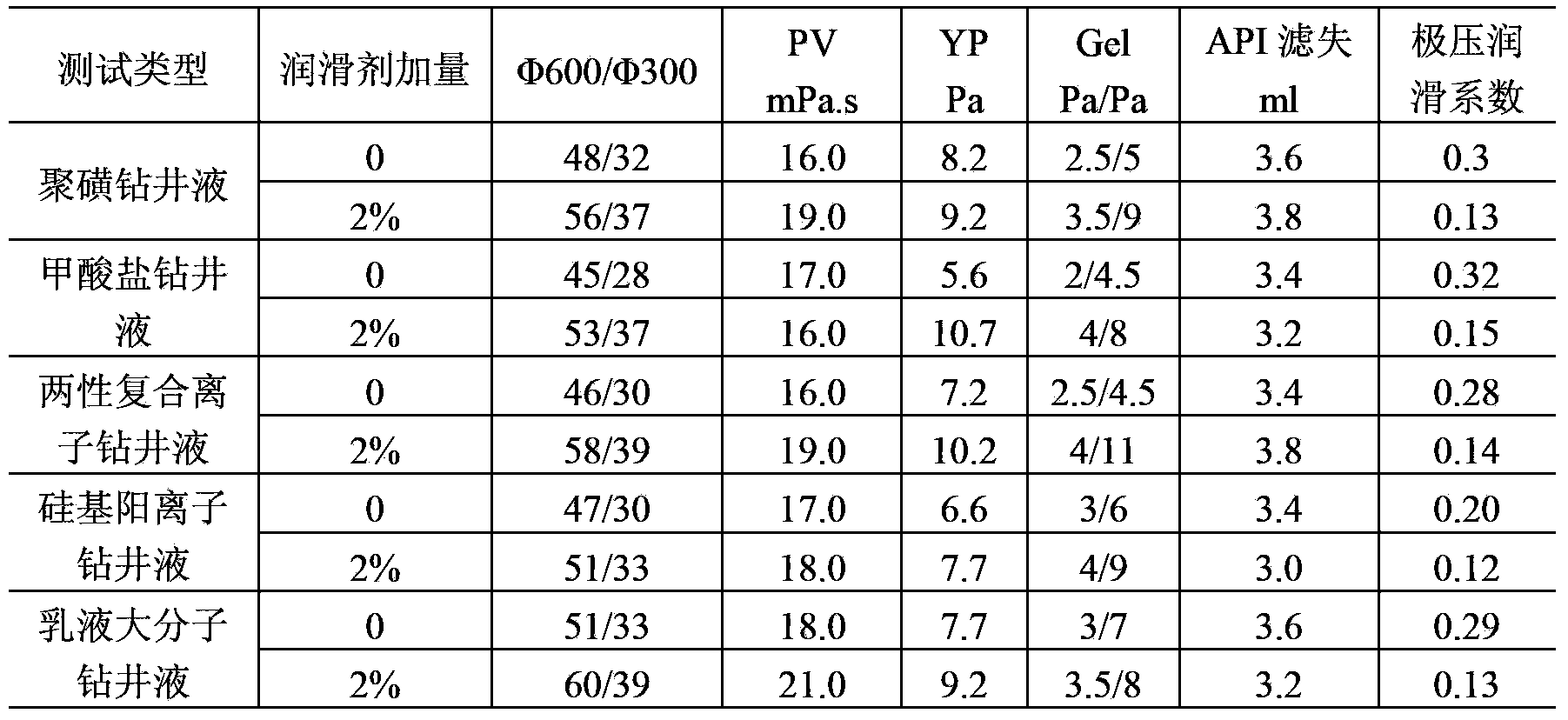

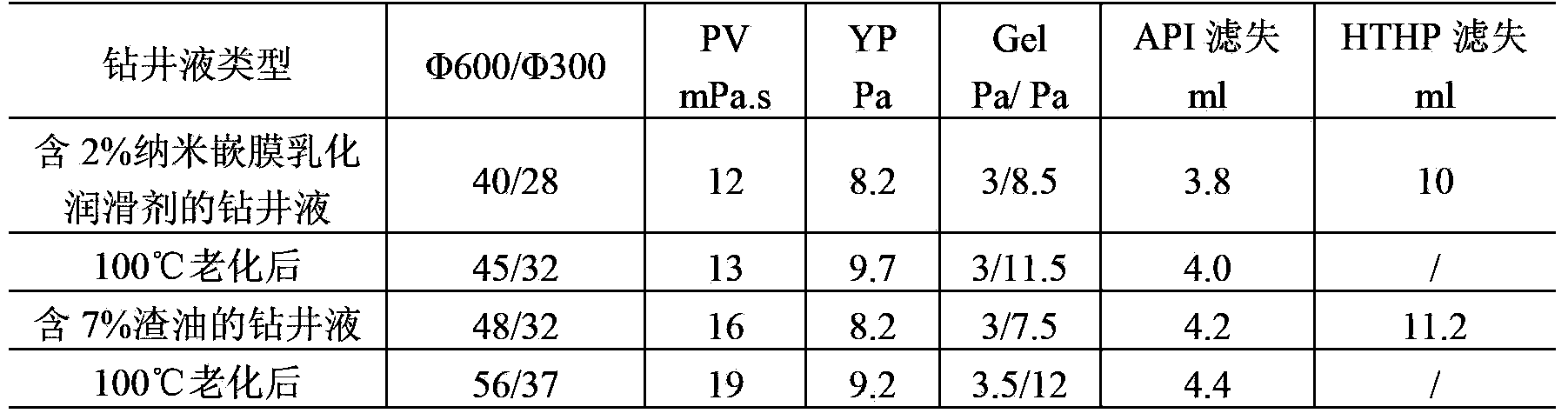

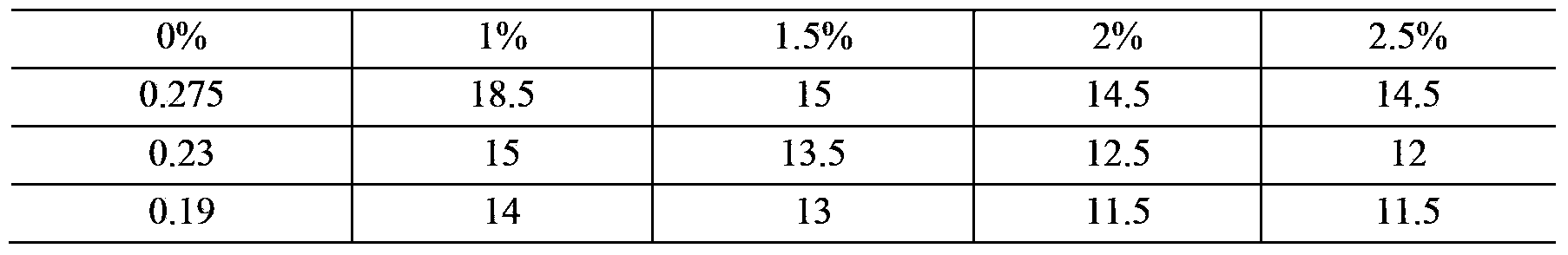

[0048] The performance evaluation of this nano-embedded emulsified lubricant is as follows:

[0049] (1) The lubricant in Example 2 was tested for compatibility in various water-based drilling fluids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com