Concrete pouring control system and method for cast-in-place pile

A technology of a control system and a control method, applied in the field of cement construction, can solve problems such as project quality uncertainty, and achieve the effects of improving pouring quality, saving material costs, and improving pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

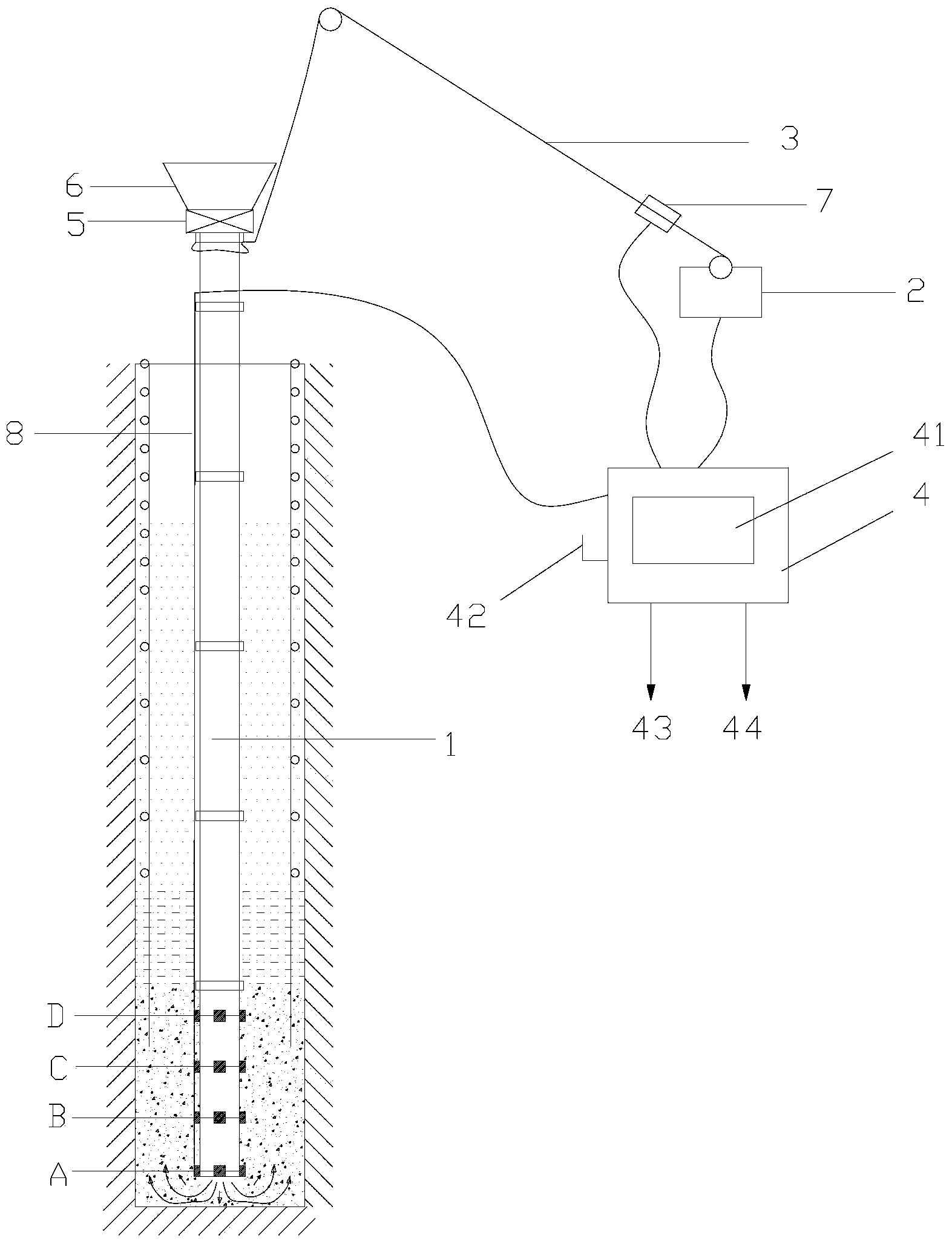

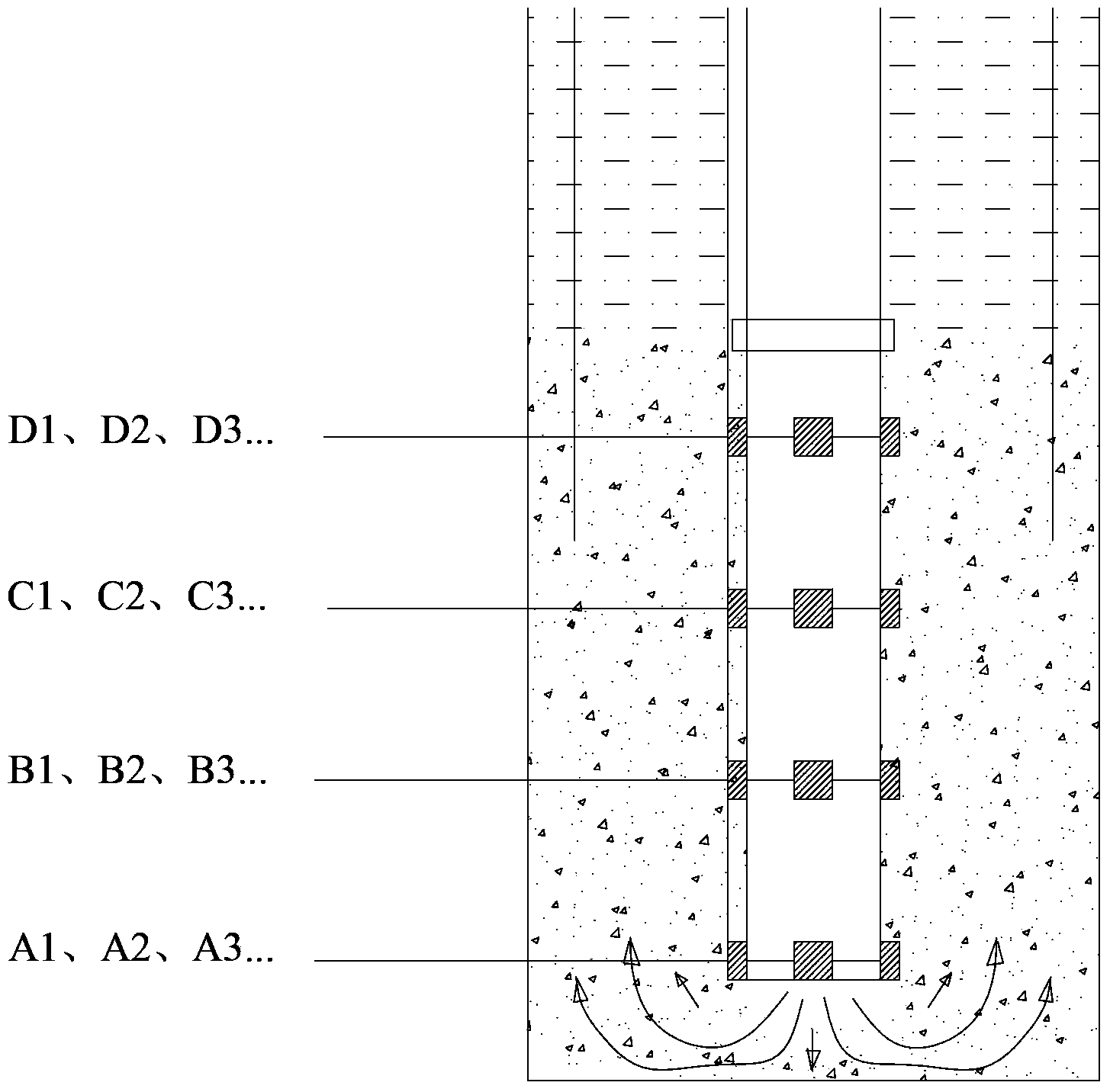

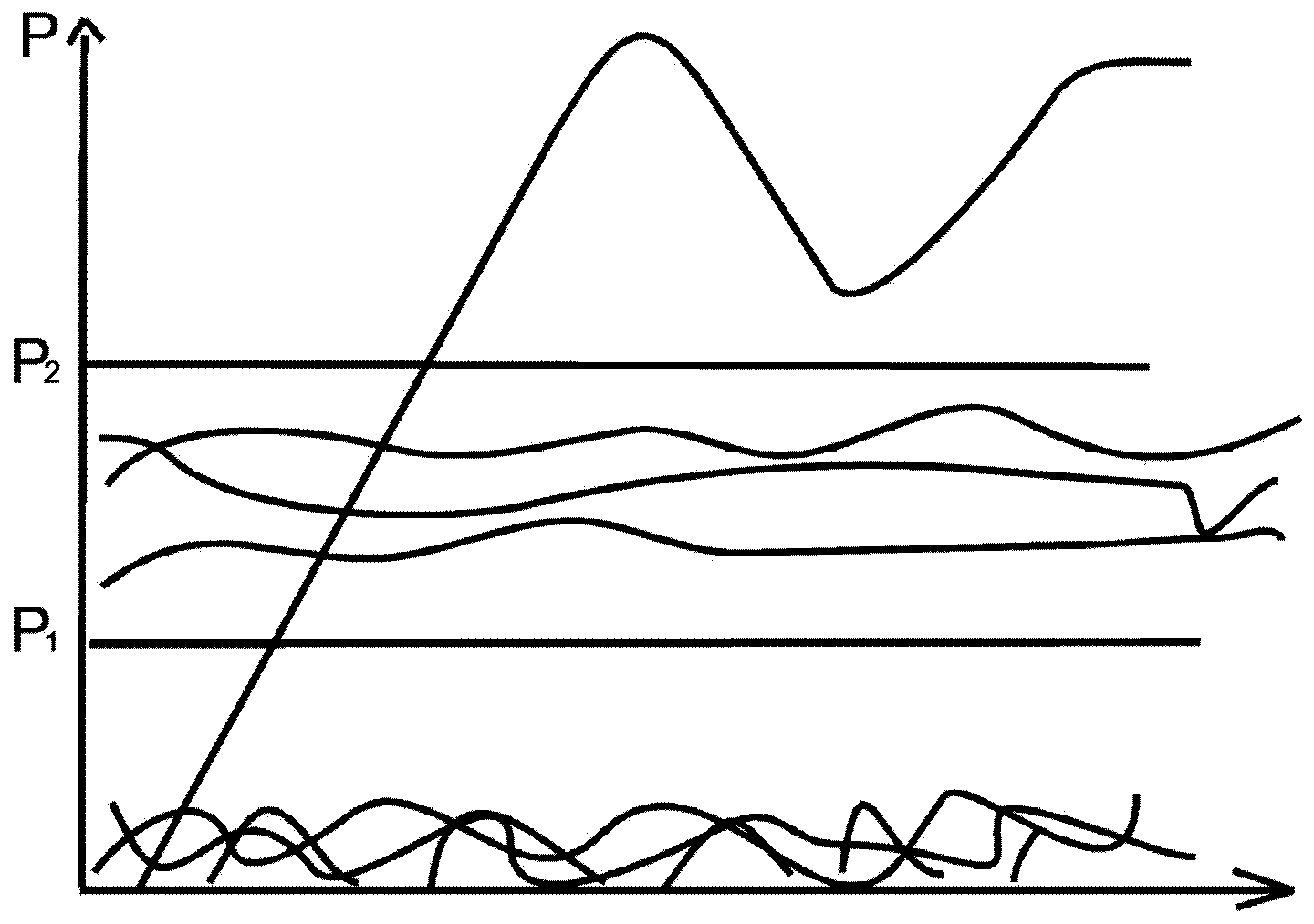

[0036] like figure 1 As shown, the present invention is equipped with at least two groups of pressure sensors A, B, C, D..., etc. at the bottom of the conduit 1. The sensors are connected to the control host through wired or wireless signals. When the bottom of the conduit 1 enters When the design elevation of the pile foundation is reached, each pressure sensor is subjected to various pressures such as water, mud, slag foam, concrete and mud mixture, flowing concrete, etc., to generate pressure signals, and send the signals to the control host 4 from time to time.

[0037] The present invention is equipped with a concrete flow meter 5 between the top of the conduit 1 and the hopper 6, which can measure the flow data of the concrete entering the conduit 1 through the hopper 6 in real time, and send the signal to the control host 4 via wired or w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com