Speed-increasing wingspan type vertical axis wind turbine

A wind turbine and vertical axis technology, which is applied to wind turbine components, wind turbines, wind turbine control, etc., can solve the problems of easy stall and low utilization rate of wind energy, and can make up for easy stall, simple and compact structure, and noise. low-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

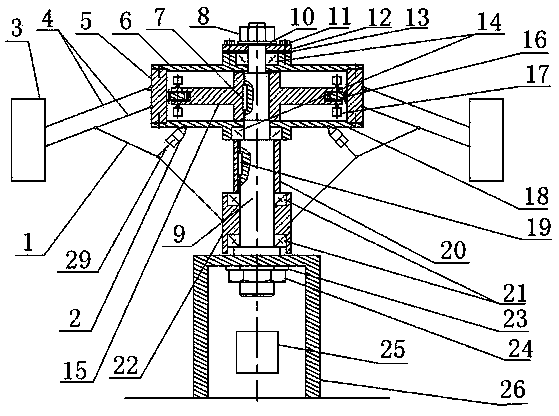

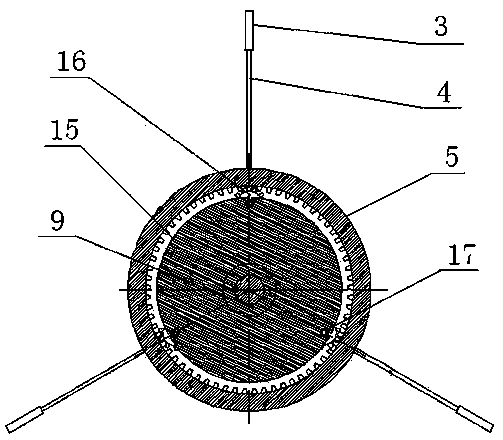

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

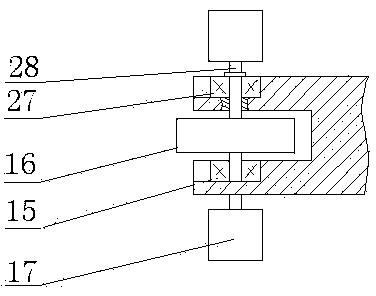

[0026] The structure of a speed-increasing wingspan type vertical axis wind power generator in the present invention is as follows: figure 1 As shown, it includes a strut 1, a hydraulic cylinder 2, a blade 3, a quadrilateral linkage mechanism 4, a rotating gear ring 5, an upper end cover 6, a first flat key 7, an upper lock nut 8, a tower frame 9, and an upper gasket 10 , fixed nut 11, bearing end cover 12, washer 13, first tapered roller bearing 14, planetary gear fixed plate 15, planetary gear 16, hydraulic pump 17, lower end cover 18, second flat key 19, sleeve 20, first Second tapered roller bearing 21, rotating sleeve 22, lower gasket 23, lower lock nut 24, control system 25, tower support platform 26, third tapered roller bearing 27, planetary gear fixed shaft 28, piston rod 29 .

[0027] The blade 3 is connected to the rotating gear ring 5 in the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com