Metal-sealing insulation jacket butterfly valve

A heat preservation jacket and metal seal technology, which is applied to control butterfly valves on process pipelines, and in the field of metal seal heat preservation jacket butterfly valves, can solve the problems of incomplete heat preservation, short service life and high cost, so as to eliminate mechanical deformation and improve service life , the effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

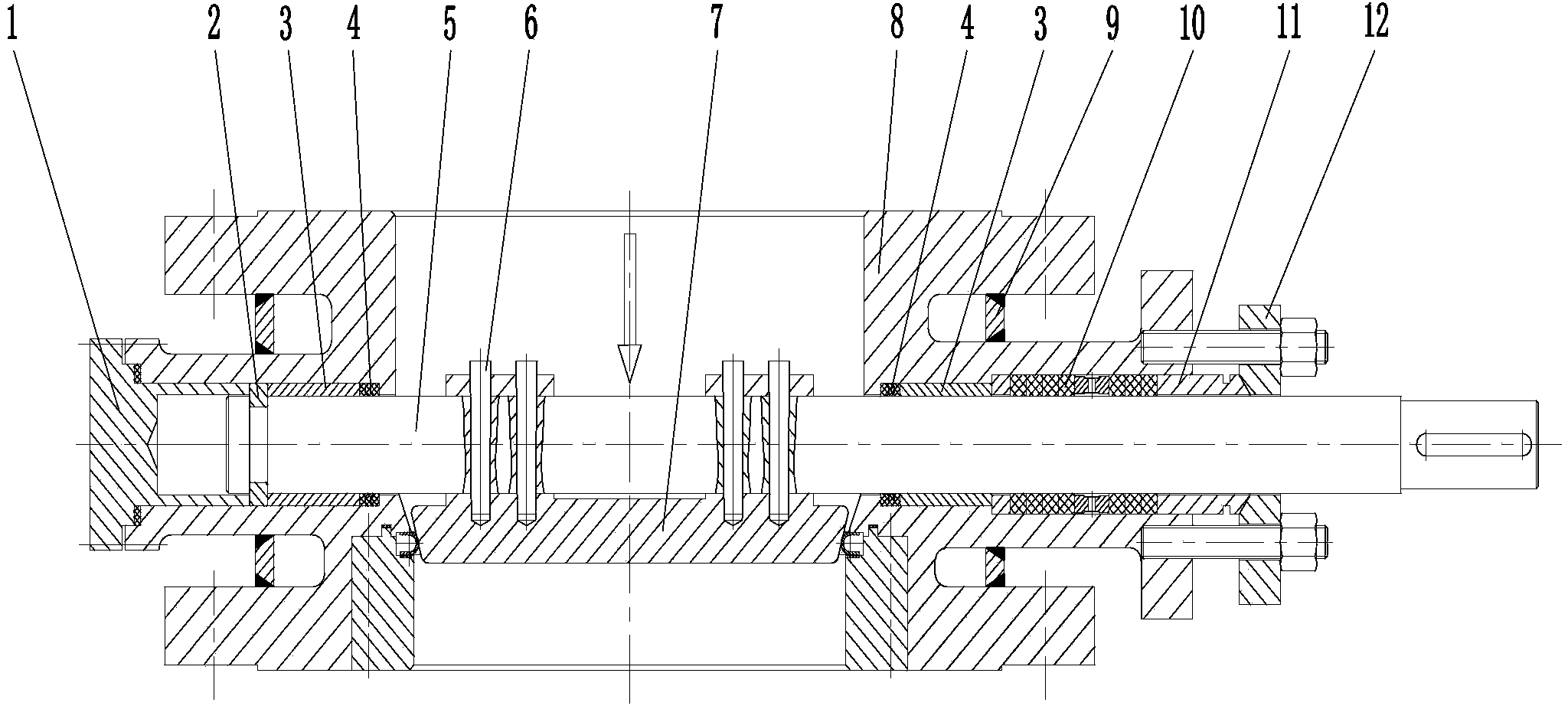

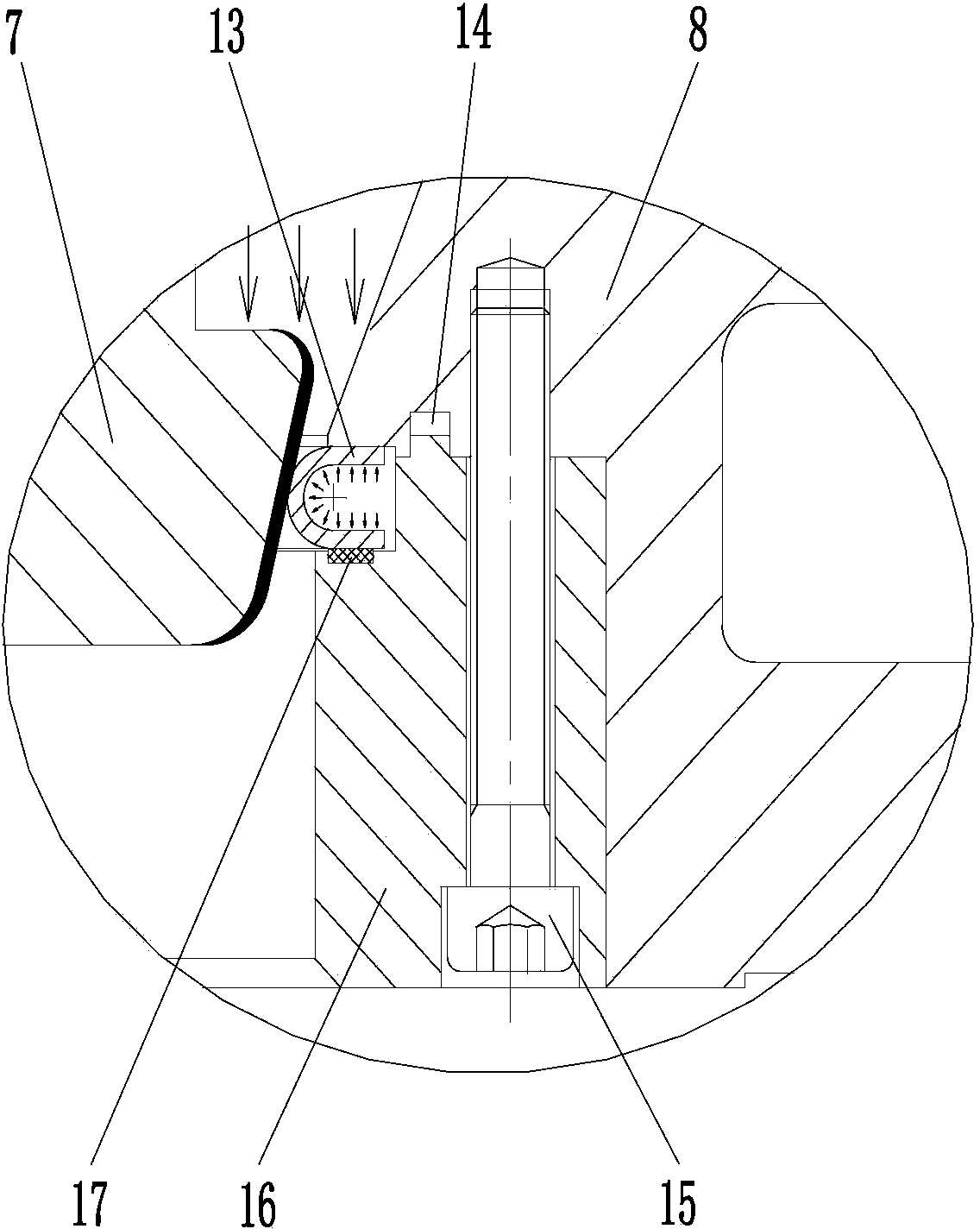

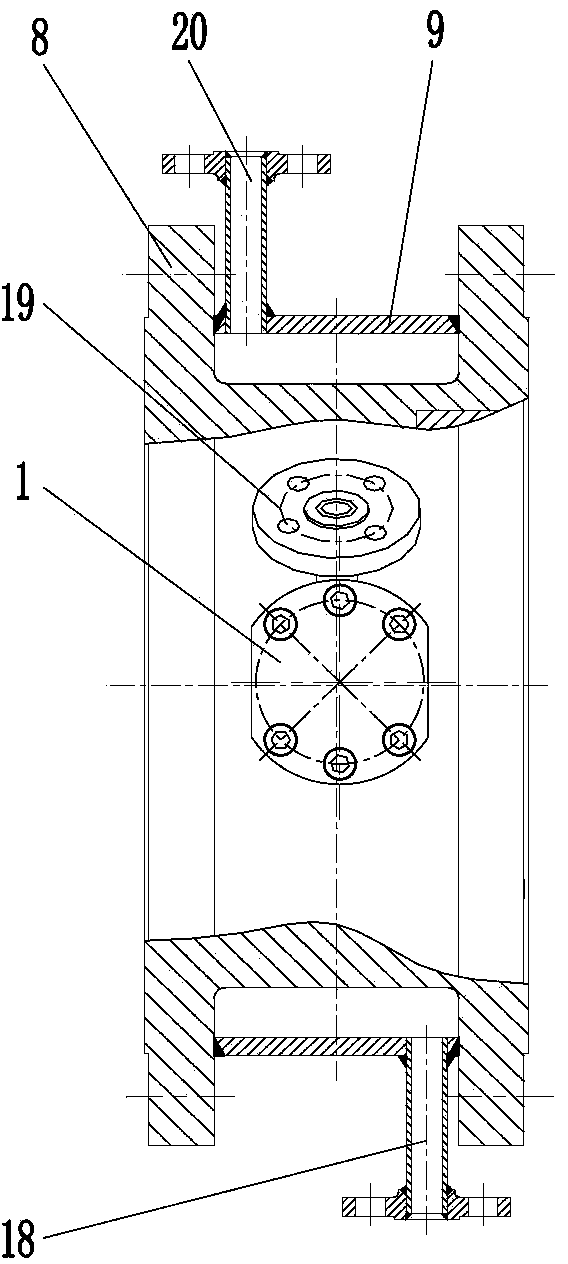

[0022] refer to figure 1 and figure 2 , the butterfly valve with metal sealing heat preservation jacket of the present invention comprises a pressure sleeve 1, a semi-open ring 2, a shaft sleeve 3, a dustproof device 4, a valve stem 5, a conical pin 6, a valve plate 7, a valve body 8, and a heat preservation jacket layer 9 , packing 10, packing gland 11, packing plate 12, U-shaped valve seat (namely: valve seat 13), sealing ring 14, hexagon socket head cap screw 15, valve seat pressure ring 16, valve seat gasket 17. The valve body 8 is an integral casting type, and the two ends of the valve body 8 are provided with bushing holes. The bushings 3 are divided into two front and rear parts, which are respectively placed in the 8 shaft bushing holes of the valve body to increase the concentricity of the valve. There is a dust-proof device 4 under the shaft sleeve 3, the dust-proof device 4 can effectively prevent the medium from entering the shaft sleeve 3, and eliminate the stuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com