Method and device for preventing membrane water wall type boiler from high-temperature corrosion and coking

A membrane-type water-cooled wall and high-temperature prevention technology, applied in the field of boiler combustion, can solve problems such as affecting boiler economy, decreasing boiler combustion efficiency, and no success, eliminating hidden dangers of high-temperature corrosion and coking, prolonging service life, and reducing maintenance. and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

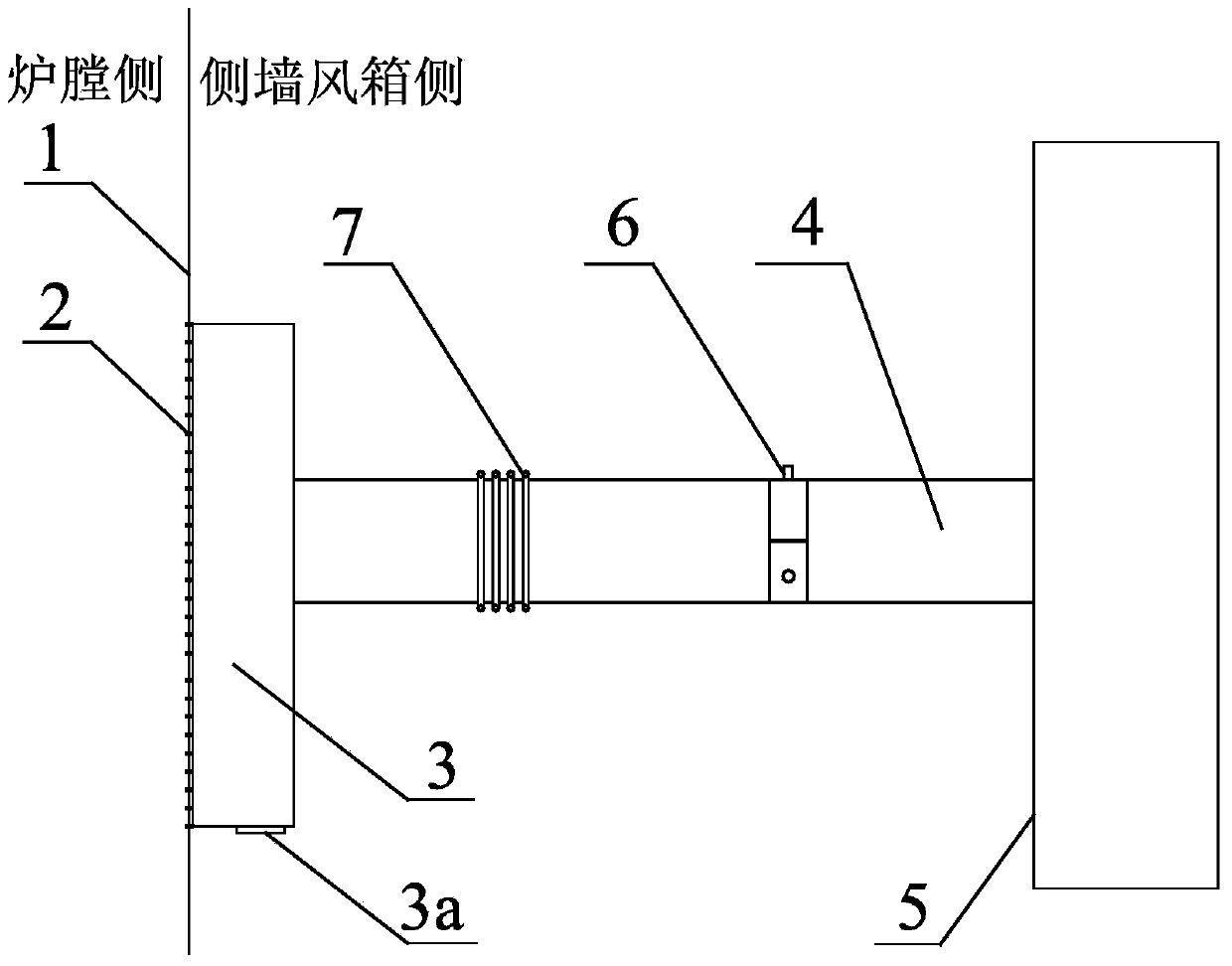

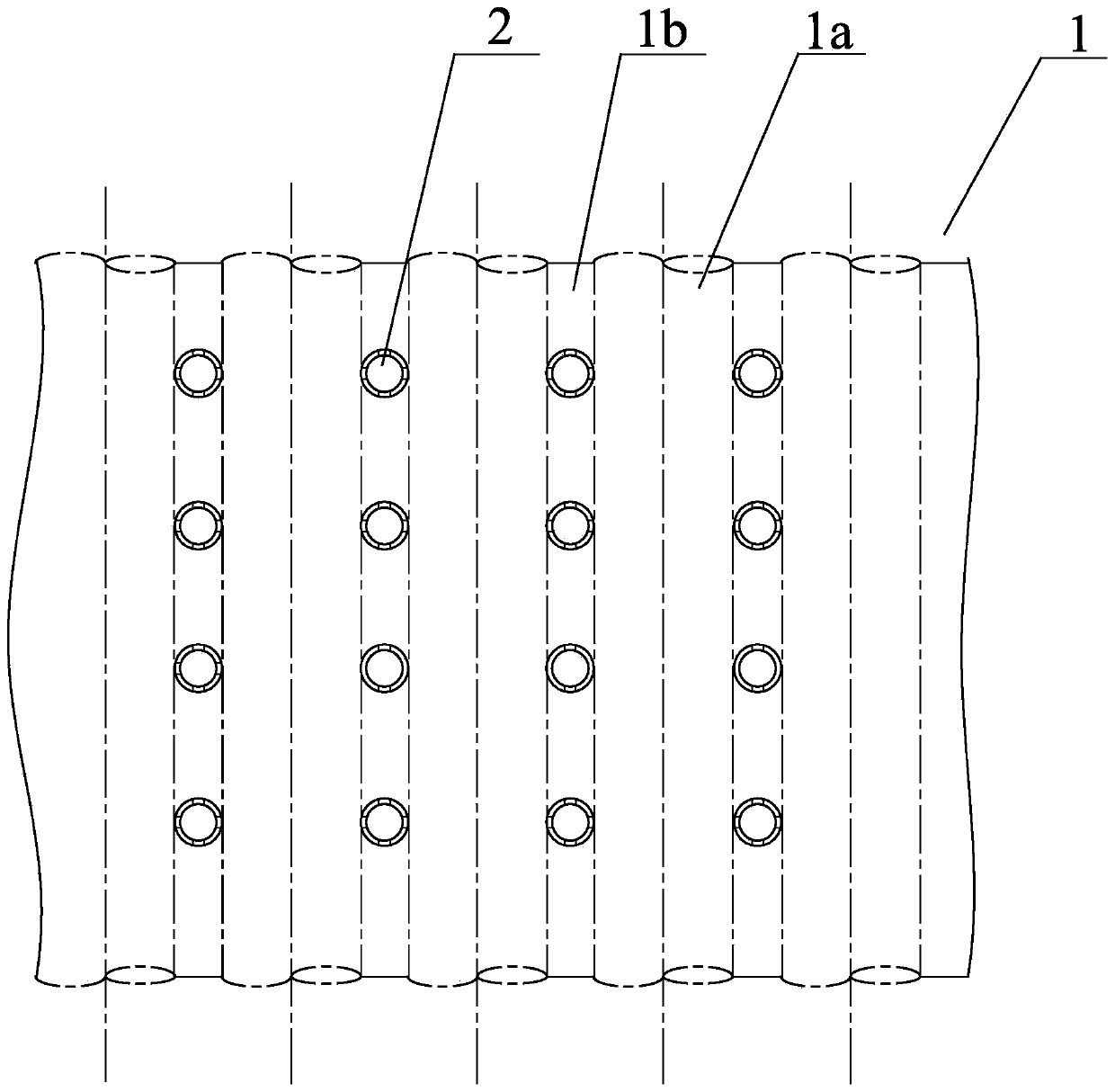

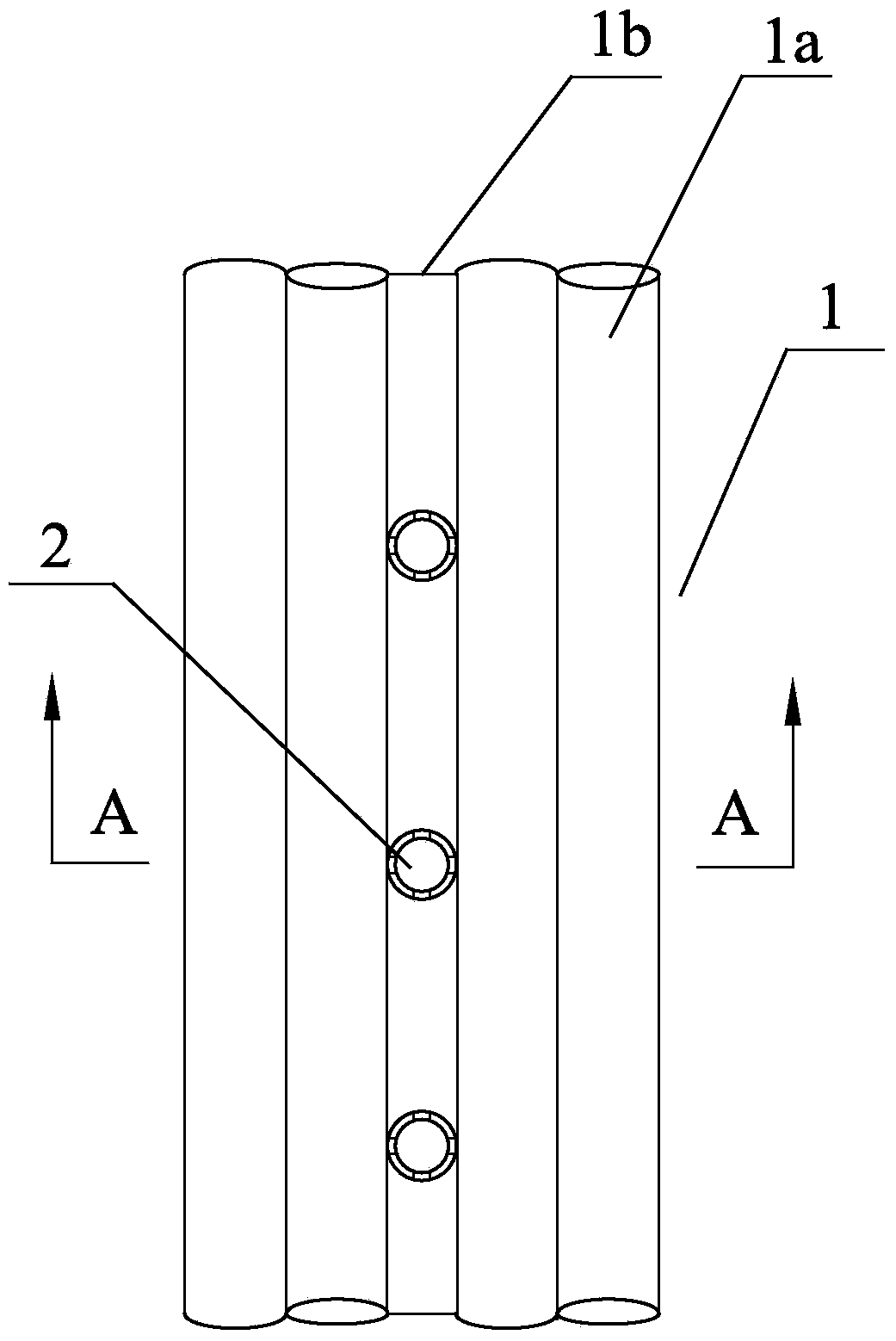

[0029] Such as Figure 1~4 The high-temperature corrosion-resistant coking device of the membrane water-cooled boiler shown in the figure includes a boiler water-cooled wall side wall 1 formed by connecting staggered water-cooled wall tubes 1a and inter-tube fins 1b. The area corresponding to the combustion zone is evenly distributed with installation through holes 1c, and the installation through holes 1c are opened on the inter-tube fins 1b in this area. The hood type nozzles 2 are welded one by one on the installation through holes 1c, which are made of heat-resistant steel, and the anti-oxidation temperature is about 1200°C. The hood type nozzle 2 is cylindrical in shape, and the top of one end extending into the inner wall of the boiler water wall side wall 1 is a capping structure 2a, and the end is evenly distributed along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com