Compound integrated heat source tower heat pump device

A technology of heat source tower heat pump and heat source tower, which is applied in heat pumps, fluid heaters, heating fuels, etc., can solve the problems of large consumption and achieve the effects of small footprint, reduced power consumption, and reduced lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

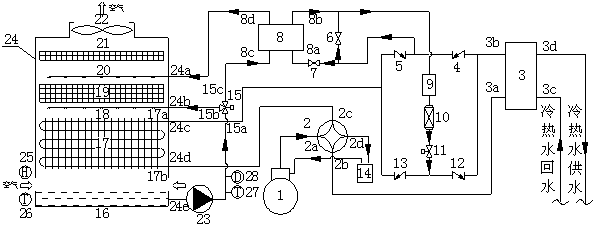

[0036] Combine below figure 1 And specific embodiment will further illustrate the present invention.

[0037] The compound integrated heat source tower heat pump device of the present invention includes a refrigerant circuit, a solution circuit, an air circuit and a cold and hot water circuit. The specific connection method is

[0038] In the refrigerant circuit, the output end of the compressor 1 is connected to the first input end 2a of the four-way valve, the first output end 2b of the four-way valve is connected to the first input end 3a of the first heat exchanger, and the first heat exchanger first The output port 3b is connected to the inlet of the first one-way valve 4 and the outlet of the third one-way valve 12 at the same time, the outlet of the first one-way valve 4 is divided into three paths, and one path passes through the input of the first solenoid valve 6 and the liquid reservoir 9 One end is connected; one way is connected with the outlet of the second one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com