Novel baffle plate

A baffle, a new type of technology, applied in the field of internal components, can solve the problems of flow dead zone, reduce the heat transfer effect of heat exchange gas, etc., and achieve the effect of increasing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

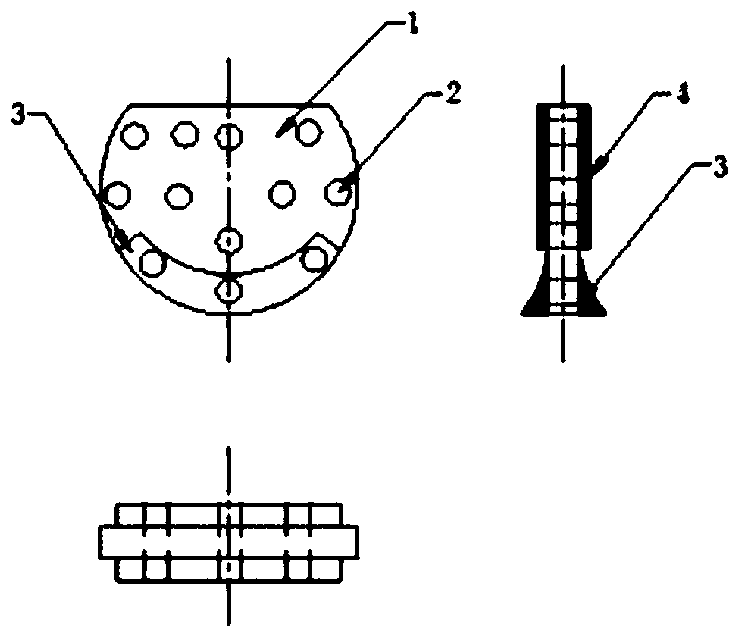

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The baffle plate 1 is a circular baffle plate made of stainless steel, with a circular channel 2 evenly opened on the surface, and the opening area accounts for 60-90% of the total area. The round hole 2 is a through hole with a diameter of 8-20mm, and when the fluid passes through the round hole 2, the degree of turbulence of the fluid is increased. The diversion structure 3 is arc-shaped and welded to the circular end surface of the baffle 1, avoiding the right-angle transition zone formed at the welding position between the baffle 1 and the condenser, and eliminating the flow dead zone formed there. The anti-corrosion layer 4 is located at the outer end surface of the baffle 1 and prevents the corrosion of the baffle 1 containing acid or alkaline pairs in the water. The baffle plate 1 installed in the condenser, when the fluid in the condenser passes through the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com