Method for controlling positive and negative commutating pulse power supply

A technology of pulse power supply and control method, which is applied in the control field of positive and negative commutation pulse power supply, can solve the problems of difficult, complex and huge control system, and achieve strong anti-interference ability, reduced complexity and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

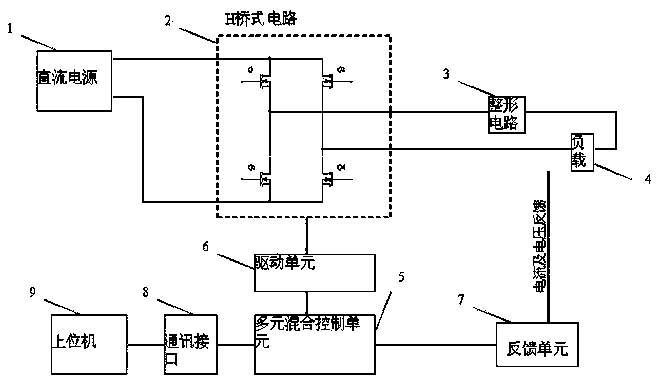

[0026] The key of the present application is to improve the existing forward and reverse commutation pulse power supply, and propose the control method of the forward and reverse commutation pulse power supply of the present application on the basis of the improved forward and reverse commutation pulse power supply.

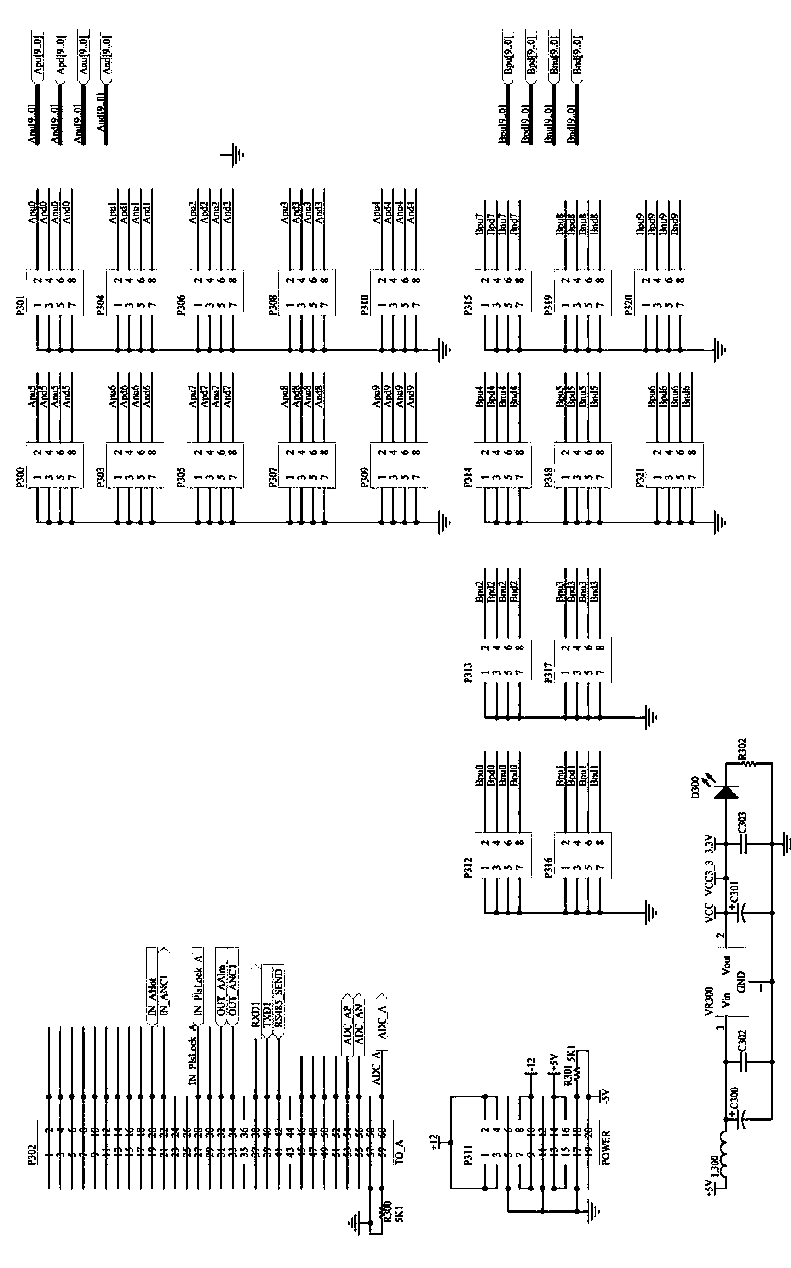

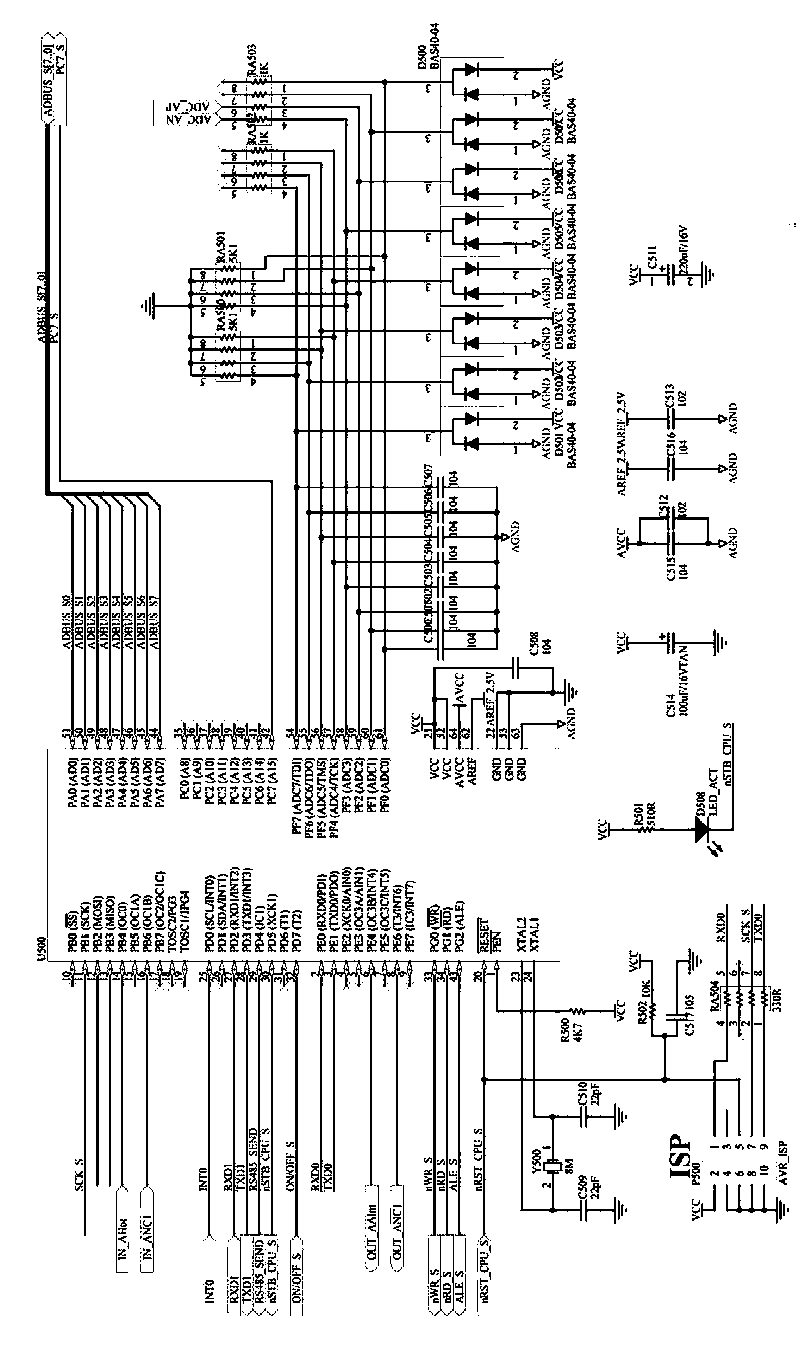

[0027] The improved positive and negative commutation pulse power supply of the present application includes a DC power supply, an H-bridge circuit, a shaping circuit, a load, a multivariate hybrid control unit, a drive unit, a feedback unit and a host computer, and the DC power supply is connected to the input end of the H-bridge circuit. The shaping circuit is connected to the output end of the H-bridge circuit after the load is connected in series. The multivariate hybrid control unit is connected to the control terminal of the H-bridge circuit through the drive unit. The load is connected to the multivariate hybrid control unit through the feedback unit. The mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com