High-tension porcelain insulator dirt cleaning device

A high-pressure porcelain bottle and cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of difficult cleaning, secondary pollution, and difficult cleaning, and achieve cleaning Reliable, prevent secondary pollution, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

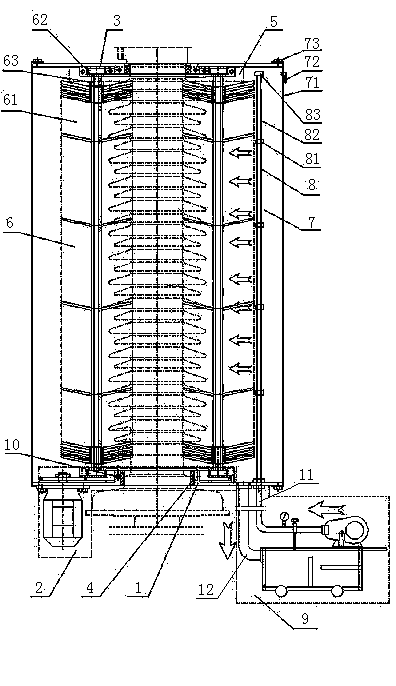

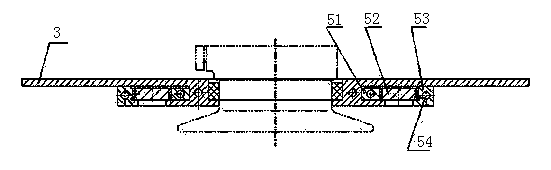

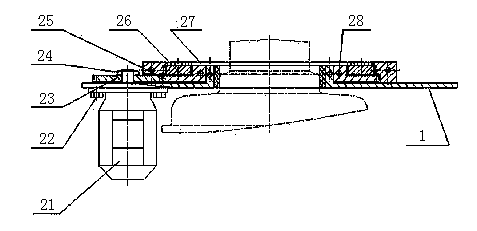

[0021] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , a high-pressure porcelain bottle dirt cleaning treatment device of the present invention consists of a bottom plate 1, a power and transmission device 2, a top plate 3, a sealing damping rubber pad 4, an upper transmission support device 5, a cleaning brush assembly 6, a splash prevention device 7, a spray liquid device 8, cleaning liquid supply and recovery device 9, bolts 10, cleaning liquid supply interface 11, and residual liquid recovery interface 12, sealing and damping rubber pads 4 are respectively arranged in the bottom plate 1 and top plate 3, and the bolts 10 respectively connect the bottom plate 1 1. The top plate 3 is fixed on the neck of the upper and lower ends of the high-pressure porcelain bottle, and the anti-splash device 7 is arranged between the bottom plate 1 and the top plate 3. The power and transmission device 2 is installed on the bottom plate 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com