Quick disc surface polishing device for disc type workpieces and working method of quick disc surface polishing device

A disc type workpiece and polishing device technology, which is applied to surface polishing machine tools, grinding workpiece supports, grinding/polishing equipment, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

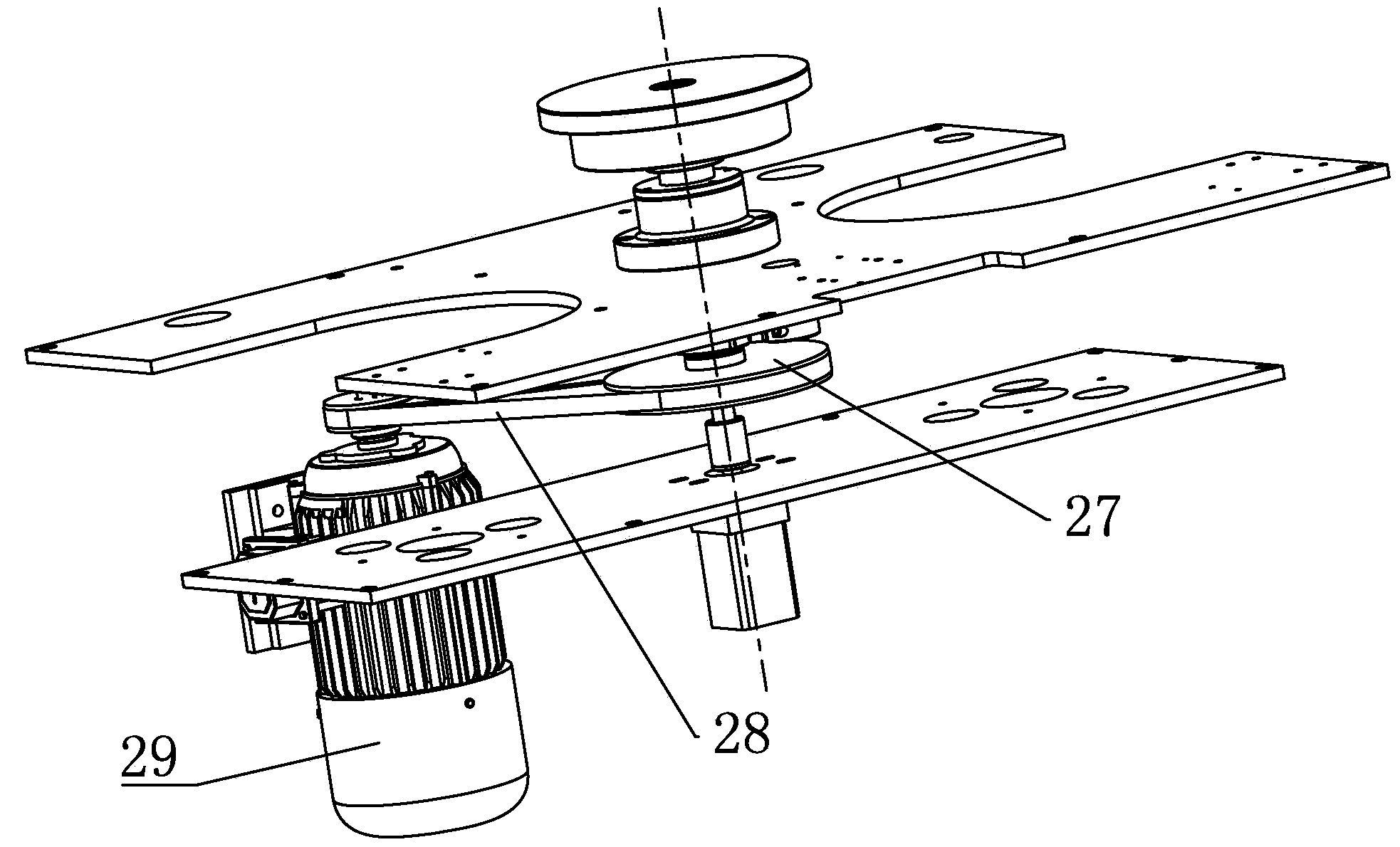

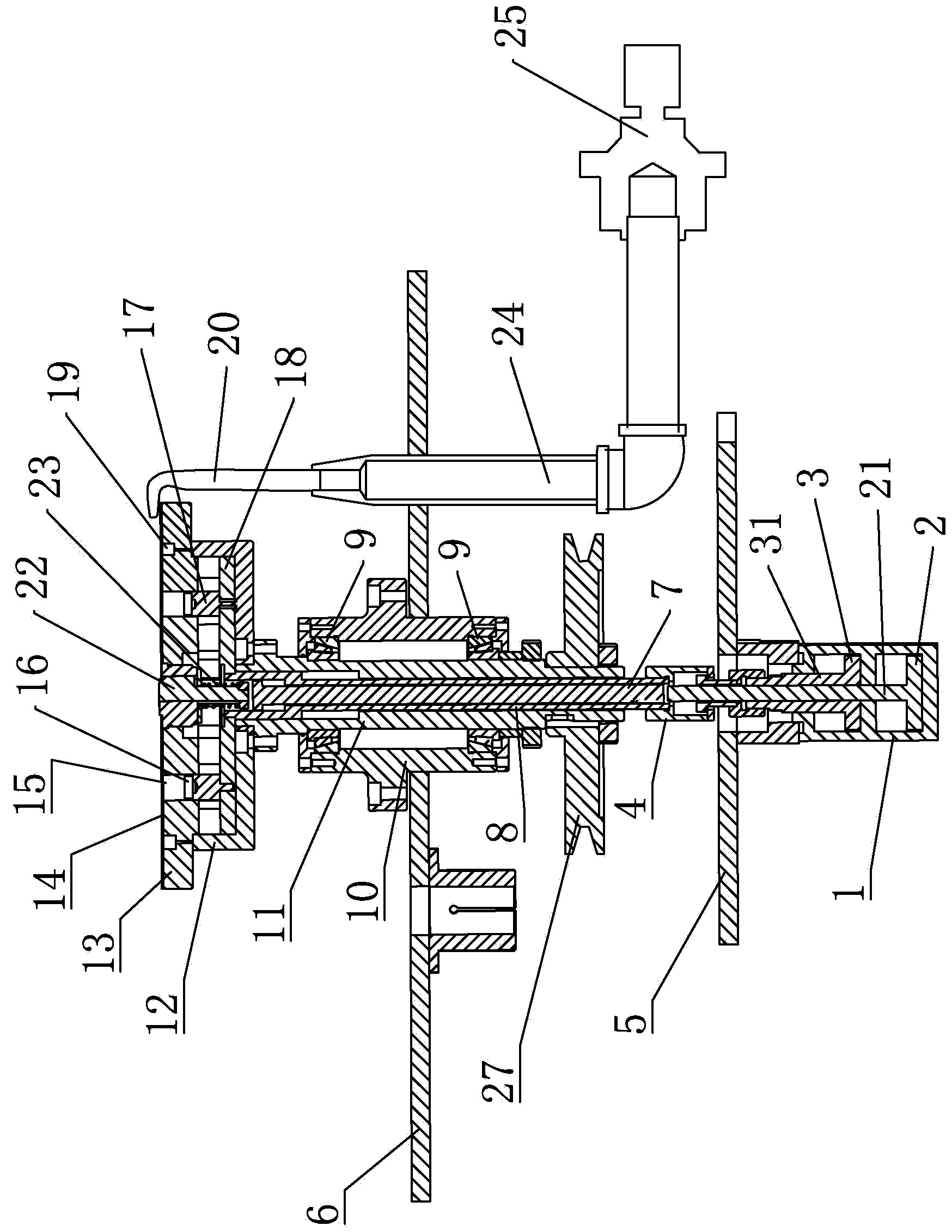

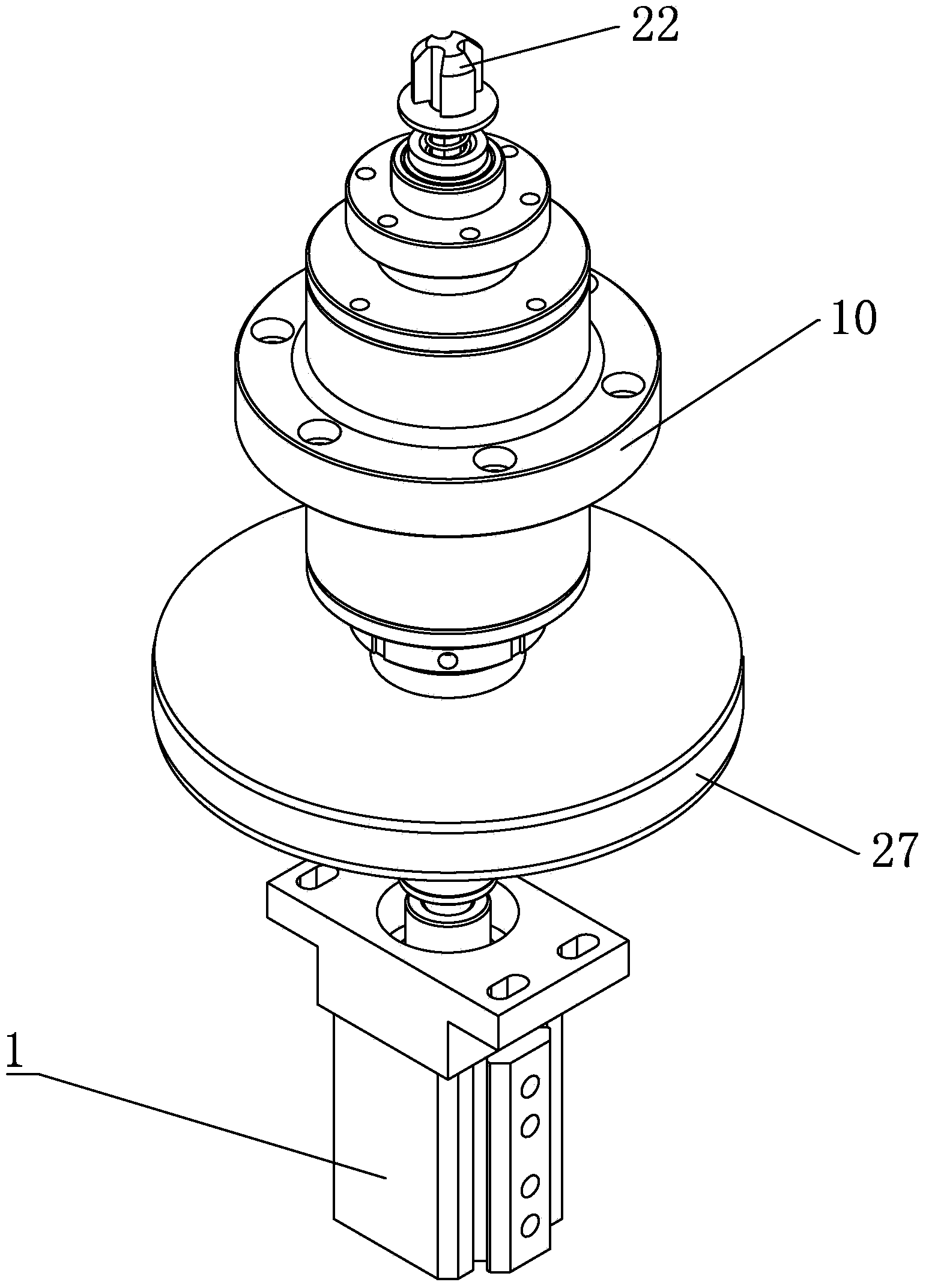

[0034] Such as figure 1 , figure 2 As shown, the disk surface rapid polishing device of the disk type workpiece of the present embodiment comprises: double-layer cylinder 1, lower piston 2, lower piston rod 21, upper piston 3, upper piston rod 31, connecting assembly 4, bridge plate 5, support Plate 6, ejector rod 7, pull rod 8, bearing 9, spindle base 10, spindle 11, table base 12, rotary table 13, rubber pad 14, positioning hole 15, permanent magnet or electromagnet 16, magnet base 17, tray 18, Threaded hole 19, nozzle 20, positioning pin 22, back-moving spring one 23, air pipe 24, pulse valve 25, locator 26, belt pulley 27, belt 28, motor 29.

[0035] The disc-shaped workpiece to be processed is a saw disc with positioning holes, and the flexible pad is a rubber pad for increasing friction.

[0036] The bridge plate 5 and the supporting plate 6 are fixedly connected with the frame, and a double-layer cylinder 1 is fixed under the bridge plate 5, and an air chamber is arr...

Embodiment 2

[0047] The disc surface rapid polishing device of the disc-shaped workpiece in this embodiment is different from that in Embodiment 1 in that the disc-shaped workpiece to be processed can be a disc with a positioning hole or other discs with a positioning hole Type workpieces, such as a saw disc with an alloy tip welded to the tip of the teeth or a saw disc with a diamond tip on the outer circle;

[0048] As a preference, the flexible pad adopts a non-woven pad or a silica gel pad with a friction coefficient similar to that of the above-mentioned rubber pad but lighter in quality;

[0049] As a preference, this embodiment eliminates the mechanism that drives the rotary table (13) to rotate, so that the rotary table (13) and the workpiece on it are fixed, and at the same time, a grinding tool that can rotate around the workpiece is used so that the grinding tool can The entire upper surface of the workpiece can be polished; or an abrasive tool whose lower surface is similar in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com