Preparation method and construction method for quick repair material of pit slot in asphalt concrete pavement

A technology for asphalt concrete and repairing materials, which is applied to the field of quick repairing materials for asphalt concrete pavements and grooves and its preparation, can solve the problems of poor quality of interface materials and uneven quality, and achieves simple construction, no toxic gas, and easy mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention is a preparation method of a quick repair material for asphalt concrete pavement potholes and construction method, The preparation method of the rapid patching material for asphalt concrete pavement potholes comprises the following steps:

[0013] (1) The preparation step of the first liquid material: heating the base asphalt to 135 o C. After adding the nano-intercalation agent, mechanically stir evenly, slowly add the solvent and continue stirring for 1-2 hours, until the temperature drops to 40-60 o After C, add aspartic acid ester, and continue stirring for 1 to 2 hours to obtain the first liquid material;

[0014] (2) The preparation step of the second liquid material: heating the base asphalt to 135 o C, slowly add the solvent and continue to stir for 1-2 hours, until the temperature drops to 40-60 o After C, add isocyanate and continue stirring for 1 to 2 hours to obtain the second liquid material;

[0015] (3) Prepare aggregate: the aggregate ...

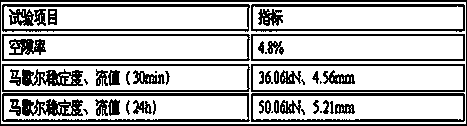

Embodiment 1

[0027] Weigh 100 parts of base asphalt, 5 parts of organic bentonite, 30 parts of diesel oil and 120 parts of aspartate to prepare the first liquid material. The preparation steps are as follows: heat the base asphalt to 135 o C. After adding the nano-intercalation agent (organic bentonite), stir mechanically evenly, slowly add the solvent and continue stirring for 1-2 hours, until the temperature drops to 40-60 o After C, add aspartic acid ester, and continue stirring for 1 to 2 hours to obtain the first liquid material;

[0028] Take 100 parts of base asphalt by weight, 30 parts of diesel oil and 120 parts of toluene diisocyanate to prepare the second liquid material. The preparation steps are as follows: heat the base asphalt to 135 o C, slowly add the solvent and continue to stir for 1-2 hours, until the temperature drops to 40-60 o After C, add toluene diisocyanate, and continue to stir for 1 to 2 hours to obtain the second liquid material;

[0029] Preparation of aggre...

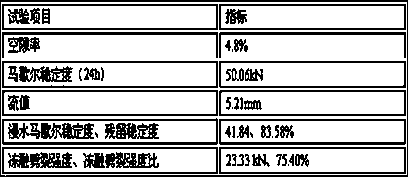

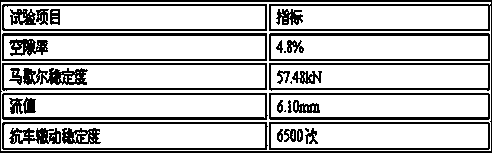

Embodiment 2

[0045] Weigh 100 parts of base asphalt, 10 parts of organic attapulgite, 20 parts of kerosene and 100 parts of aspartate to prepare the first liquid material. The preparation steps are as follows: heat the base asphalt to 135 o C. After adding the nano-intercalation agent (organic attapulgite), stir mechanically evenly, slowly add the solvent and continue stirring for 1-2 hours, until the temperature drops to 40-60 o After C, add aspartic acid ester, and continue stirring for 1 to 2 hours to obtain the first liquid material;

[0046] Take 100 parts of base asphalt by weight, 20 parts of kerosene and 100 parts of diphenylmethane diisocyanate to prepare the second liquid material. The preparation steps are as follows: heat the base asphalt to 135 o C, after slowly adding the solvent, continue to stir for 1-2 hours until the temperature drops to 40-60 o After C, add diphenylmethane diisocyanate, and continue stirring for 1 to 2 hours to obtain the second liquid material;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com