Energy-saving and efficient municipal sewage treatment plant construction method

A municipal sewage and treatment plant technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as increased energy consumption, difficult site selection, increased construction costs, etc., to achieve Strong impact load resistance, full denitrification, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

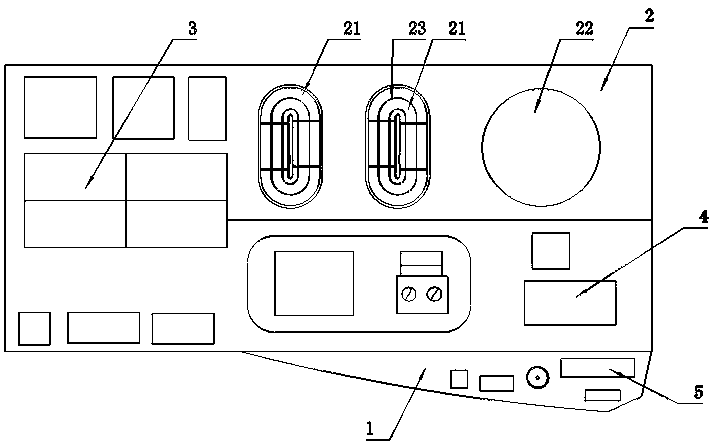

[0085] Embodiment 1: as figure 1 As shown in ~6, a method for constructing an energy-saving and efficient municipal sewage treatment plant is characterized by following the steps below:

[0086] a. Level the site, build pretreatment section 1, secondary biological treatment section 2, advanced treatment section 3, disinfection section 4 and sludge treatment section 5 in sequence; the pretreatment section passes through secondary biological treatment section, advanced treatment section and disinfection section connected;

[0087] b. Construct the pretreatment section: the pretreatment section includes coarse screens and lifting pump stations, fine screens and aeration grit chambers, fine screens and primary sedimentation tanks; One end is connected to the water inlet of the lifting pump station, the water outlet of the lifting pump station is connected to one end of the fine grid, the other end of the fine grid is connected to the water inlet of the aeration grit chamber, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com