Welding repair material for repairing coking furnace and method for repairing coking furnace

A welding repair material and coke oven technology, which is applied in the field of welding repair material to repair coke ovens and ceramic welding materials, can solve the problems of harsh operating environment, lower furnace wall surface temperature, and short one-time material hanging time, etc., and achieve good damage effect , to achieve self-heating sintering, good environmental and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the soldering material for coke oven repair and the coke oven repair method according to the present invention will be described in detail with reference to exemplary embodiments. In the present invention, if there is no exception statement, the content of each element or component in the commonly mentioned substances is the weight percentage (expressed in "wt%").

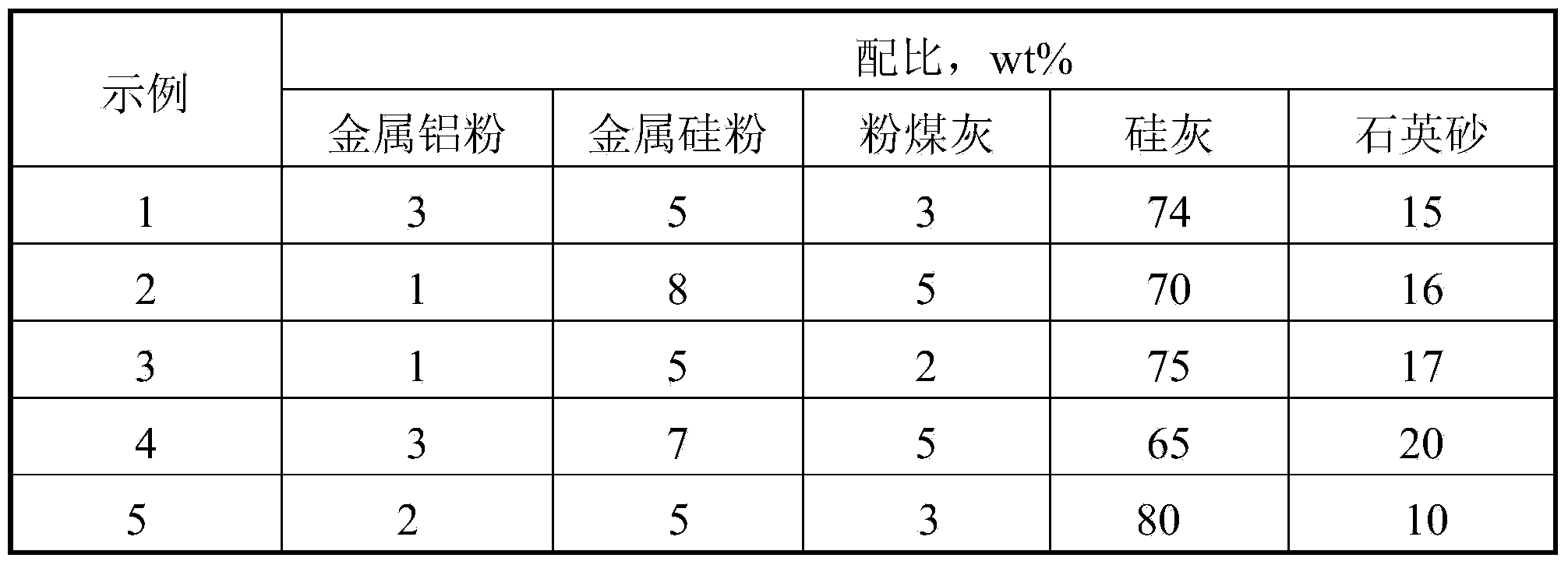

[0018] According to the coke oven repair welding filling material according to the exemplary embodiment of the present invention, by weight percentage, it is composed of 1-3% metal aluminum powder, 5-8% metal silicon powder, 2-5% fly ash, 65 ~85% silica fume and 10~20% quartz sand.

[0019] Wherein, the particle size of the metal aluminum powder used is below 150 mesh (that is, it can pass through a 150 mesh sieve), and the metal aluminum content is above 98wt%. The particle size of metal silicon powder is below 200 mesh (that is, it can pass through a 200 mesh sieve), and the metal silicon con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com