Vacuum pipeline automatic dust removal system and method of dry vacuum pumping system for molten steel refining

A technology of vacuum pumping system and vacuum pipeline, which is applied in the field of cleaning pipeline system, can solve problems such as suffocation of workers, secondary pollution of the environment, and harsh working environment, and achieve the effects of convenient operation and maintenance, high degree of automation, and good dust cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

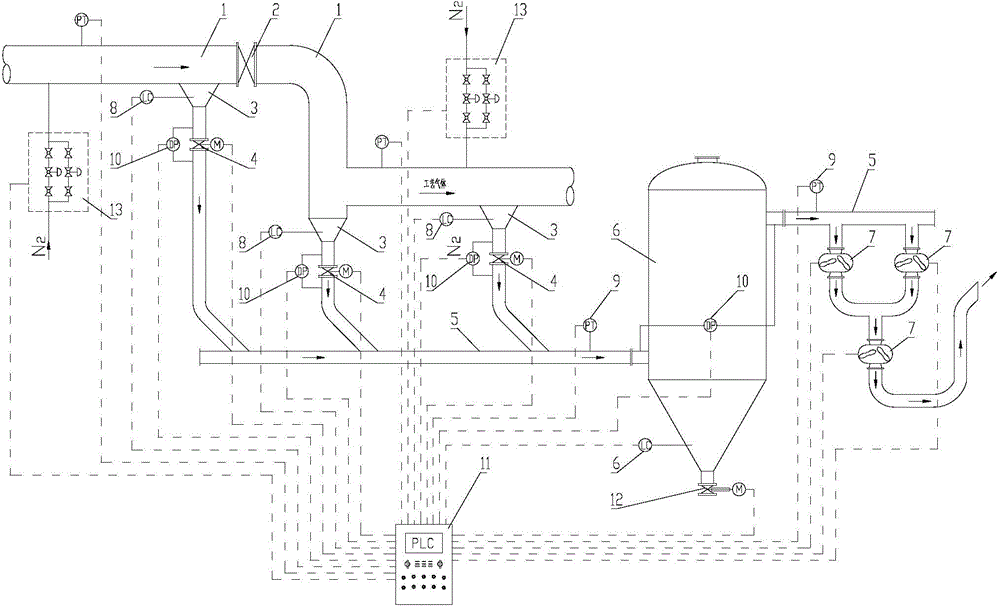

[0026] Such as figure 1 Shown is a structural schematic diagram of the vacuum pipeline automatic dust removal system of the molten steel refining dry vacuum system of the present invention. The vacuum pipeline automatic dust removal system of the molten steel refining dry vacuum system of the present invention includes a vacuum pipeline 1 There is not less than one ash accumulation cone 3, an electric ash removal valve 4, a filter 6 and a vacuum system arranged at the outlet of each ash accumulation cone 3, and each of the electric ash removal valves 4 passes through the ash removal The pipeline 5 is connected with the filter 7 and the vacuum system in turn, and also includes a vacuum recovery device 13 arranged on the vacuum pipeline 1 and an automatic control system for controlling the operation of the electric dust cleaning valve, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com