A method for improving the performance of corrosion inhibitors in industrial cooling water systems

A cooling water system and corrosion inhibitor technology, which is applied in the field of improving the performance of corrosion inhibitors in industrial cooling water systems, and can solve problems such as high cost of chemicals and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

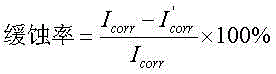

[0026] In simulated water containing 0, 0.5, 1, 2, 3, 5mg / L benzotriazole respectively, the corrosion current density of brass was tested to be 0.82, 0.49, 0.17, 0.12, 0.16 and 0.18μA / cm 2 , Under this condition, the corrosion inhibition rates of benzotriazole with concentrations of 0.5, 1, 2, 3, and 5 mg / L on brass were calculated to be 40.2%, 79.3%, 85.4%, 80.5% and 78.0%, respectively.

Embodiment 2

[0028] In blank simulated water, the corrosion current density of brass is 0.82μA / cm 2 . After the simulated water was treated with frequency conversion DC pulse electromagnetic water processor for 0.5h and 1h respectively, the corrosion current density of brass was tested to be 0.84μA / cm 2 . The results show that pure electromagnetic treatment has no corrosion inhibition performance on brass;

[0029] The frequency conversion DC pulse electromagnetic water processor has a power supply of AC 220V, 50Hz, a working voltage of DC 10-15V, an output power of 100-300W, a frequency conversion range of 20Hz~75KHz, and a carrier frequency of 1MHz.

Embodiment 3

[0031] The simulated water containing 0, 0.5, 1, 1.5, 2, 3, and 5mg / L benzotriazole respectively, after being treated by a frequency conversion DC pulse electromagnetic water processor for 0.5h, the corrosion current density of brass was detected to be 0.84 , 0.27, 0.13, 0.11, 0.084, 0.12 and 0.095μA / cm 2 , the corrosion inhibition rates of benzotriazole with concentrations of 0.5, 1, 2, 3, and 5 mg / L on brass under this condition were calculated to be 67.9%, 84.5%, 86.9%, 90.0%, 85.7% and 88.7%, respectively. %;

[0032] The frequency conversion DC pulse electromagnetic water processor has a power supply of AC 220V, 50Hz, a working voltage of DC 10-15V, an output power of 100-300W, a frequency conversion range of 20Hz~75KHz, and a carrier frequency of 1MHz.

[0033] Compare by above-mentioned embodiment 1, embodiment 2 and embodiment 3, the result shows:

[0034] In the case of purely using benzotriazole without electromagnetic treatment, when the concentration of benzotria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com