Asbestos cement board foam sandwich environmentally-friendly partition board

A technology of cement boards and partition boards, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of low non-clay new wall materials, poor oxidation resistance, and poor thermal insulation effect, so as to improve housing quality. The effect of quality and construction efficiency, time-saving and labor-saving installation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

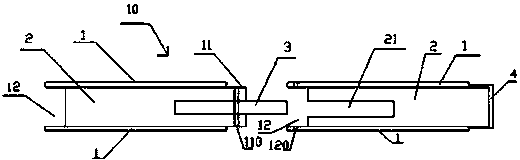

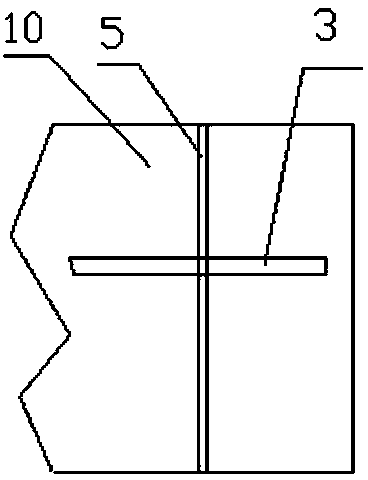

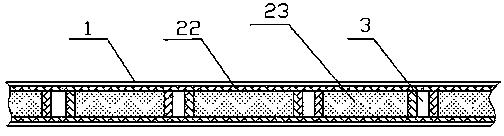

[0021] see Figure 1 to Figure 3 , a kind of asbestos cement board foam sandwich environmental protection partition wall board 10 of the present embodiment, its material is mainly silicate, asbestos, glass fiber etc., it comprises two asbestos cement boards 1 as the panel, and this panel is through high-strength silicic acid Composite extrusion of salt cement PC32.5, asbestos and glass fiber machine, with A-level strength. A sound-insulating and moisture-proof foam board 2 as a sandwich material is arranged between the two asbestos cement boards 1, and a light steel keel 4 is fixed around the sound-proof and moisture-proof foam board 2 by a universal glue, and the light steel keel 4 is a national standard light steel keel. There is a bayonet on i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com