Gob expanding material prestressed filling method and prestressed filling material

A filling material and expansion material technology, applied in the method and its prestressed filling material, goaf expansion material prestressed filling field, can solve the problem that it is difficult to effectively control the displacement and deformation of the rock mass around the ore body, and the depletion of easy-to-mine resources on the surface, etc. problem, achieve the effect of increasing strength and improving stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

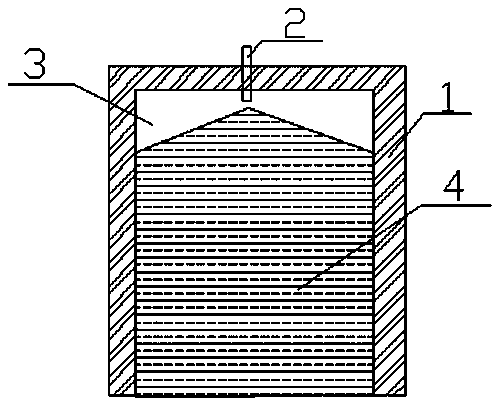

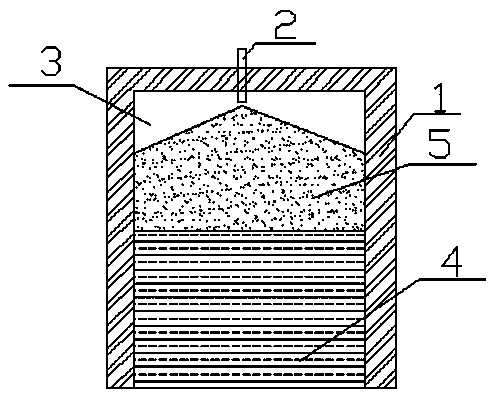

[0030] A method for prestressed filling with expansive material in a gob, comprising the steps of:

[0031] 1) Preparation of prestressed filling materials: according to the mass percentage of each raw material: 37.5% of calcined calcium oxide powder, 25% of water, 37.5% of filling aggregate, and calcined calcined oxide powder (as the cementitious material) , water and filling aggregate; stir and mix percalcined calcium oxide powder, water and filling aggregate to obtain prestressed filling material;

[0032] The filling aggregate is river sand.

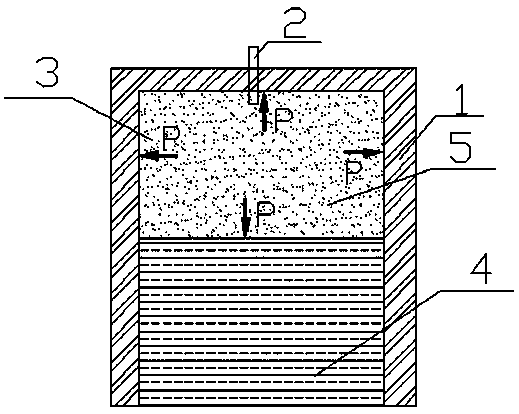

[0033] 2) According to the actual needs of the mine, on the basis of filling some of the original filling materials used in the mine, the prestressed filling material is filled into the goaf through the filling pipe (ie, the conveying pipeline) until the top of the goaf; prestressed filling After the material enters the goaf for a certain period of time, the volume expands, and after filling the entire gob, it will produce a certain...

Embodiment 2

[0037] A method for prestressed filling with expansive material in a gob, comprising the steps of:

[0038] 1) Preparation of prestressed filling materials: according to the mass percentage of each raw material: 50% of calcined calcium oxide powder, 25% of water, 25% of filling aggregate, select calcined calcined oxide powder (as the cementitious material) , water and filling aggregate; stir and mix percalcined calcium oxide powder, water and filling aggregate to obtain prestressed filling material;

[0039] The filling aggregate is river sand.

[0040] 2) According to the actual needs of the mine, on the basis of filling some of the original filling materials used in the mine, the prestressed filling material is filled into the goaf through the filling pipe (that is, the conveying pipeline) until the top of the goaf; prestressed filling After the material enters the goaf for a certain period of time, the volume expands, and after filling the entire gob, it will produce a cer...

Embodiment 3

[0044] A method for prestressed filling of expansive materials in goafs, comprising the steps of:

[0045] 1) Preparation of prestressed filling material: according to the mass percentage of each raw material: 37.5% of percalcined calcium oxide powder, 25% of water, 37% of filling aggregate and 0.5% of additives, select percalcined calcium oxide powder (as cementitious material), water, filling aggregate and additives; mix the percalcined calcium oxide powder, water, filling aggregate and additives to obtain the prestressed filling material;

[0046] The filling aggregate is river sand

[0047] The additive is a naphthalene-based high-efficiency water reducer.

[0048] 2) According to the actual needs of the mine, all the prestressed filling materials are filled in the goaf, and the prestressed filling materials are filled into the goaf through the filling pipe (that is, the conveying pipeline) until the top of the goaf; the prestressed filling material After entering the go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com