Water-cooled internal combustion engine cylinder head and water-cooled internal combustion engine with same

A technology for internal combustion engines and cylinder heads, which is applied to cylinder heads, machines/engines, cylinders, etc., and can solve the problems of large casting pollution and affecting the release and core pulling of die-casting molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

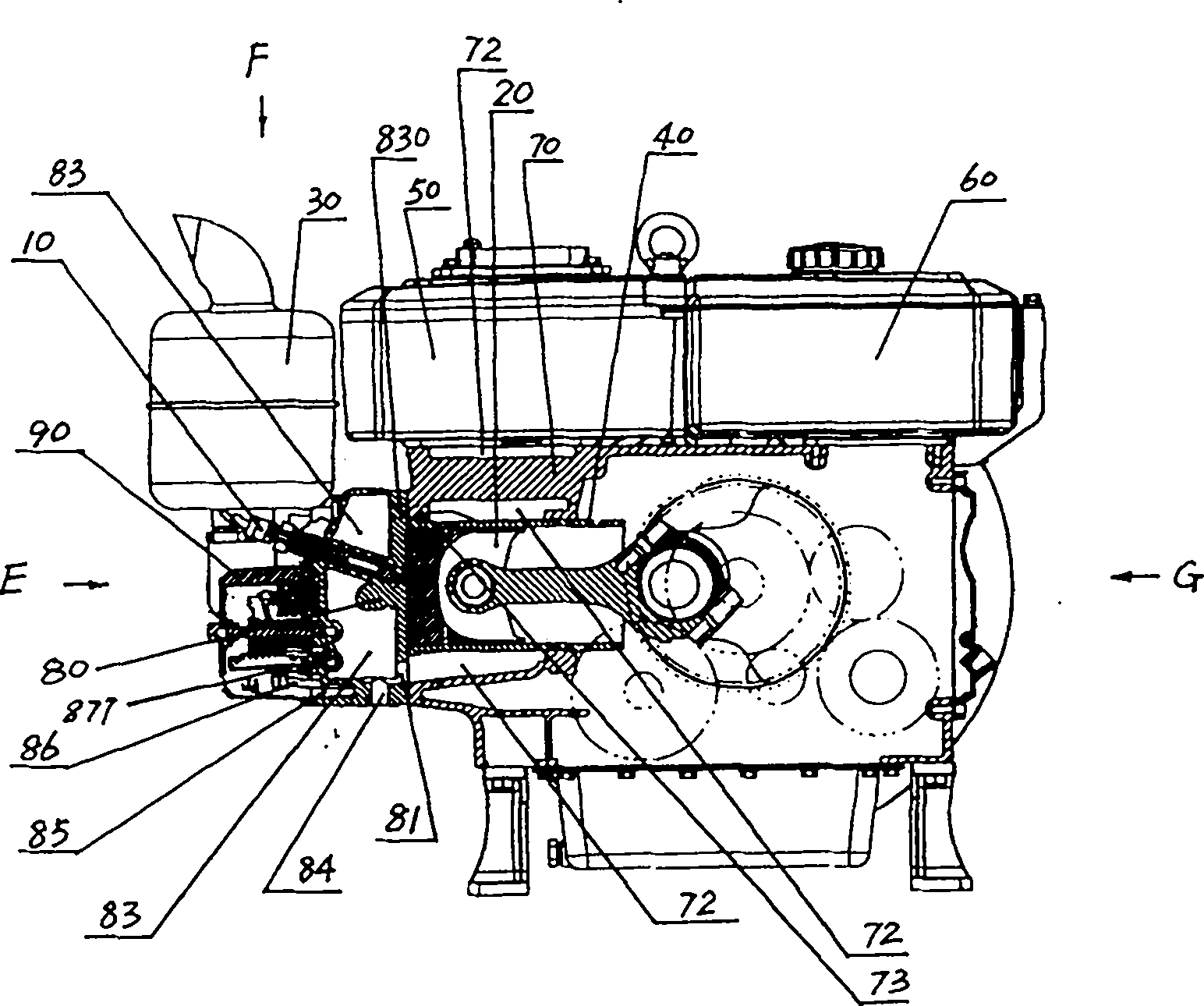

[0057] exist figure 1 In , the dotted line expresses that the upper water hole 830 of the cylinder head is connected with the body and the water hole 73 of the cylinder head. The shape of the water cavity 83 of the cylinder head 80 is complex, surrounded by a shell, and can only be cast with sand cores. .

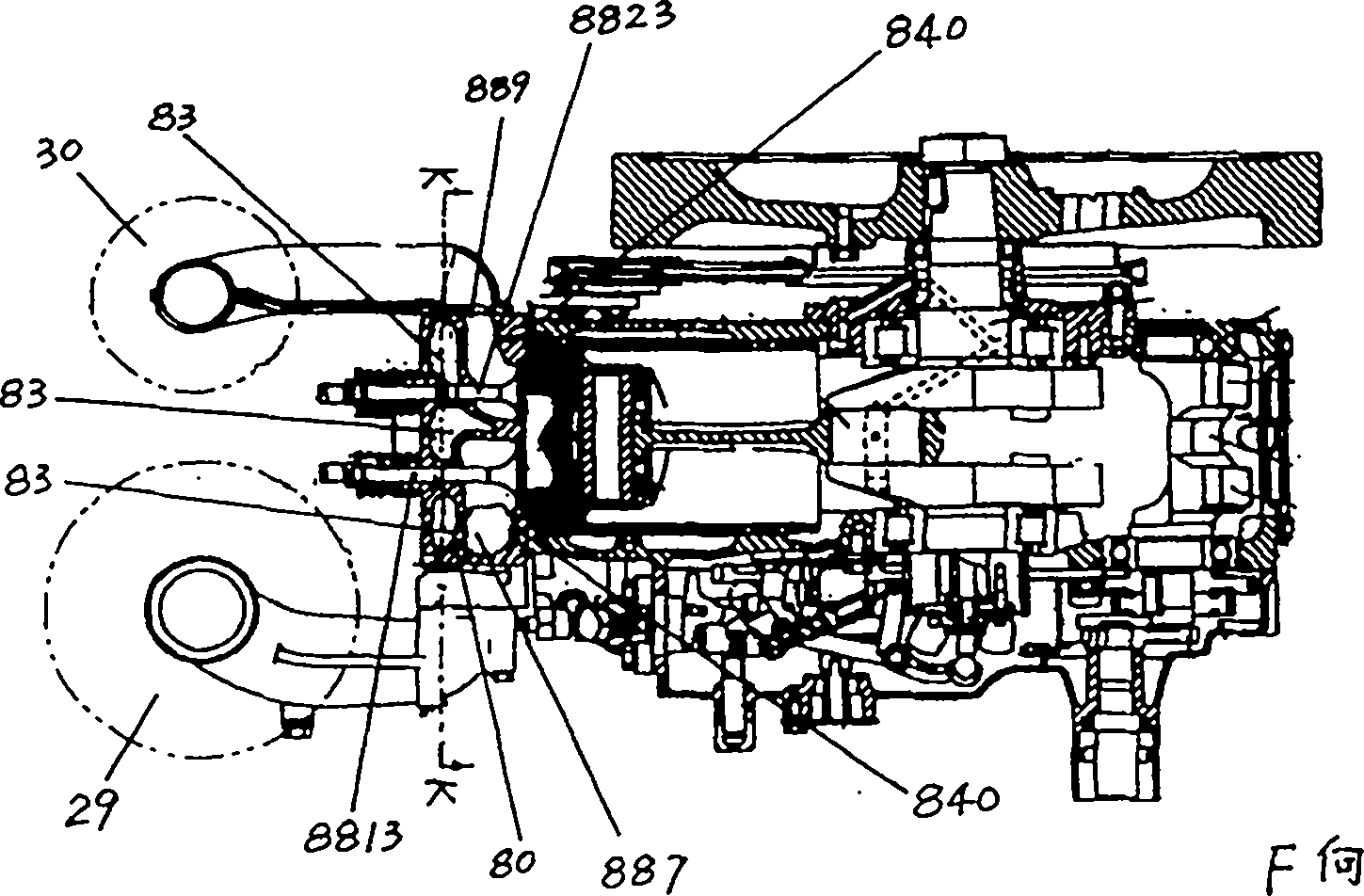

[0058] exist figure 2 Among them, the water chamber 83 of the cylinder head 80 accommodates the complex shapes of the air intake passage 887 and the exhaust passage 889, and the prior art cannot realize die-casting demoulding. It is a traditional prejudice that the cylinder head can only be cast as a whole, and the water cavity can only be cast with a mud core. The inventor chose the k-k parting surface to divide the cylinder head into an upper cylinder head and a lower cylinder head and make them separately, so that the die-casting demoulding and core pulling can be realized, and the water cavity, intake port, exhaust port and fuel injector hole can be formed by die-cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com