High sintering roller way kiln

A technology of high-temperature sintering and roller table, which is applied in the direction of measuring devices, material analysis by means of microwaves, instruments, etc., can solve problems such as insufficient microwave power density, difficult microwave coupling and matching, and failure to realize mixing, etc., to overcome product cracking and improve Performance consistency, the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

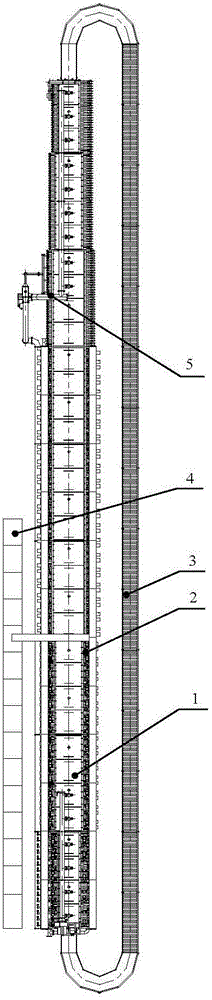

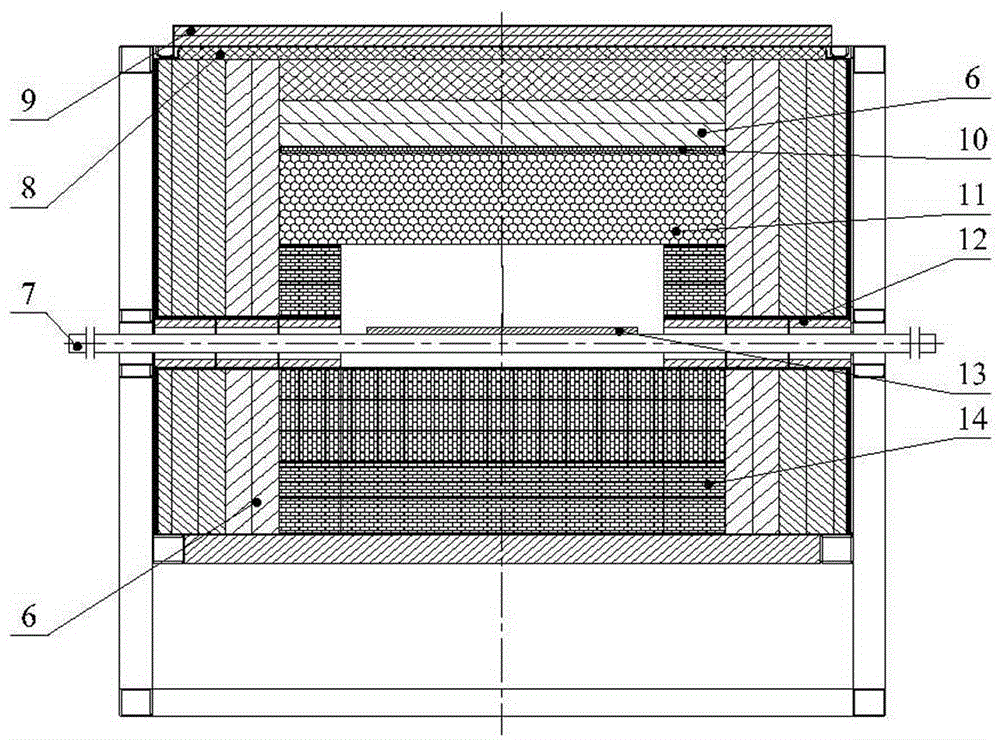

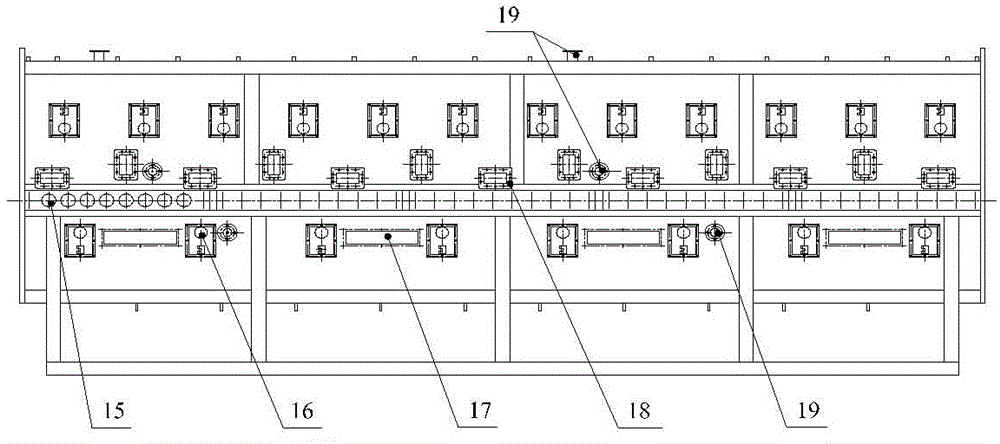

[0046] A high temperature sintering roller kiln, such as figure 1 and 11 As shown, it is mainly composed of kiln body 1, heating system 2, transmission system 3, exhaust system 5 and measurement and control system 4. The working principle of the high-temperature sintering roller kiln is: load the material on the push plate placed on the transmission system 3, and the push plate moves continuously inside the kiln body system 1 driven by the transmission system 3; in the measurement and control system 4 After the sintering process temperature curve is set on the man-machine interface, the temperature measured by the thermocouple installed on the top of the kiln body system 1 is processed by the measurement and control system 4, and then the signal is fed back to each controlled heating element in the heating system 2 for heating. By adjusting the valve of the exhaust system 5, the temperature of the inlet and outlet of the kiln body system 1 and the air content in the furnace o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com