Method for measuring surface activation degree of modified powder material

A technology of surface activation and powder materials, applied in the direction of weighing by removing certain components, can solve problems that affect the stability and accuracy of measurement results, agglomeration, and instability of modified powders, so as to improve reliability and stability, strong lipophilicity, and the effect of expanding the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Dry the industrial papermaking sludge modified with stearic acid at 105°C for 4 hours, then cool it in a silica gel drier for 30 minutes to reach a dry state, and then weigh 2.00g of the modified industrial sludge Papermaking sludge (modified powder material), standby;

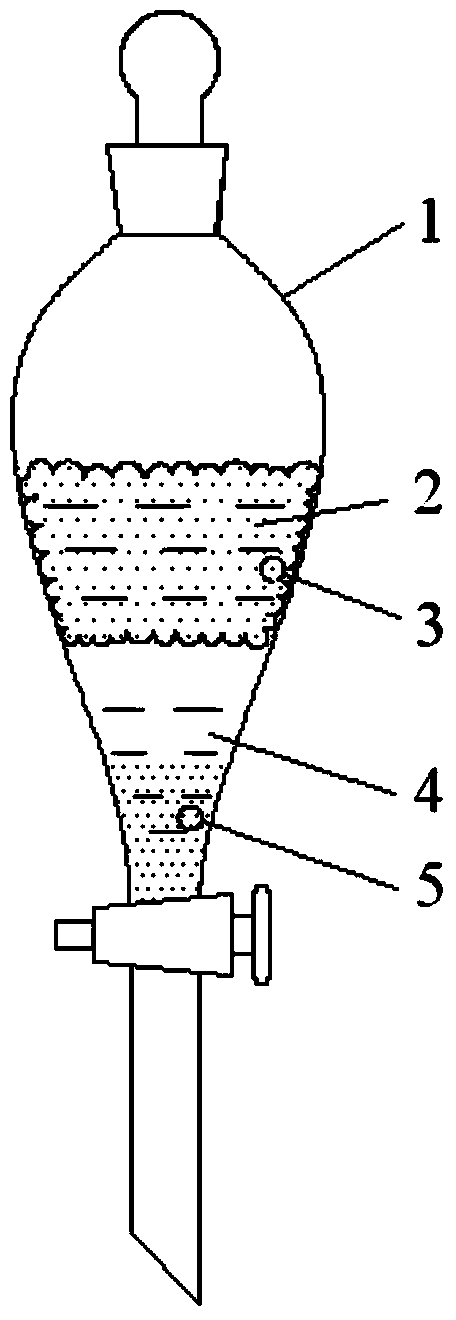

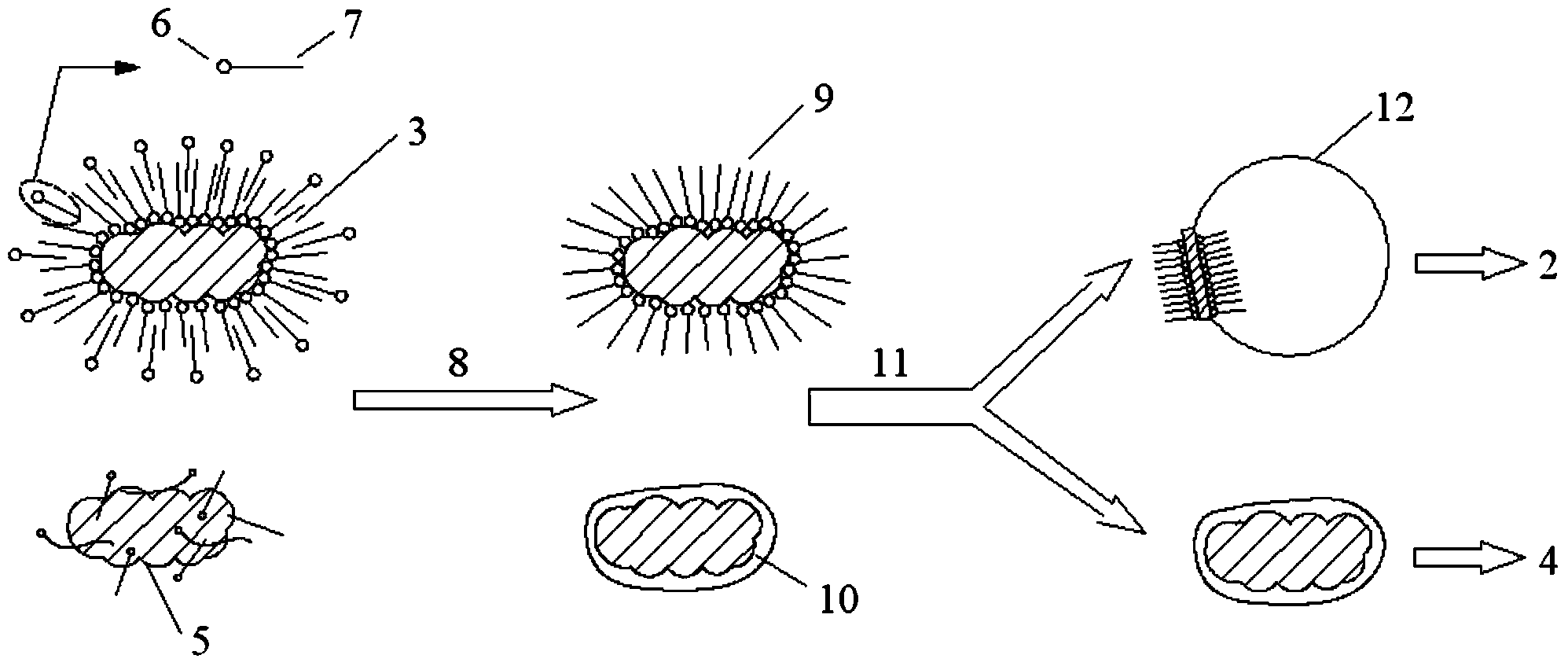

[0039] 2) Measure 40mL of distilled water and add it to a 250mL pear-shaped separatory funnel, add the weighed dry modified industrial papermaking sludge into the pear-shaped separatory funnel (the ratio of solid to liquid is 0.05g / mL), Cover the pear-shaped separatory funnel and shake it up and down for 90 times, so that the surface of the modified powder material that has not been modified by the modifier in the modified powder material is wetted by water, then lightly put it on the funnel stand, and let it stand for 30s ;

[0040] 3) Measure 40mL of liquid paraffin into the pear-shaped separating funnel (the volume ratio of liquid paraffin and water is 1:1), cover the pear-shaped separating funne...

Embodiment 2

[0044] 1) Dry the industrial papermaking sludge modified with titanate NDZ311 at 100°C for 4 hours, then cool it in a silica gel drier for 30 minutes to reach a dry state, and then weigh 2.00g of the modified sludge Industrial papermaking sludge (modified powder material), standby;

[0045] 2) Measure 40mL of distilled water and add it to a 250mL pear-shaped separatory funnel, add the weighed dry modified industrial papermaking sludge into the pear-shaped separatory funnel (the ratio of solid to liquid is 0.05g / mL), Cover the pear-shaped separatory funnel and shake it up and down for 60 times, so that the surface of the modified powder material that has not been modified by the modifier in the modified powder material is wetted by water, then lightly put it on the funnel stand, and let it stand for 30s .

[0046] 3) Measure 40mL of liquid paraffin into a pear-shaped separating funnel (the volume ratio of liquid paraffin to water is 1:1), cover the pear-shaped separating funne...

Embodiment 3

[0050] 1) Dry the industrial paper sludge modified with silane coupling agent KH550 at 110°C for 4 hours, then cool it in a silica gel desiccator for 30 minutes to reach a dry state, and then weigh 2.00g of dry modified sludge industrial papermaking sludge (modified powder material), for standby;

[0051] 2) Measure 50mL of distilled water and add it to a 250mL pear-shaped separatory funnel, add the weighed dry modified industrial papermaking sludge into the pear-shaped separatory funnel (the ratio of solid to liquid is 0.04g / mL), Cover the pear-shaped separating funnel and shake it up and down for 120 times, so that the surface of the modified powder material that has not been modified by the modifier in the modified powder material is wetted by water, then lightly put it on the funnel stand, and let it stand for 30s .

[0052] 3) Measure 25mL of liquid paraffin into a pear-shaped separating funnel (the volume ratio of liquid paraffin to water is 1:2), cover the pear-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com