Macrostructure acid etching method and full-automatic macrostructure acid etching system

A low-magnification, fully automatic technology, applied in analytical materials, instruments, etc., can solve the problems of hydrochloric acid splashing, harmful to human health of equipment, etc., and achieve the effect of saving consumption, safety quality inspection, and avoiding hydrochloric acid splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

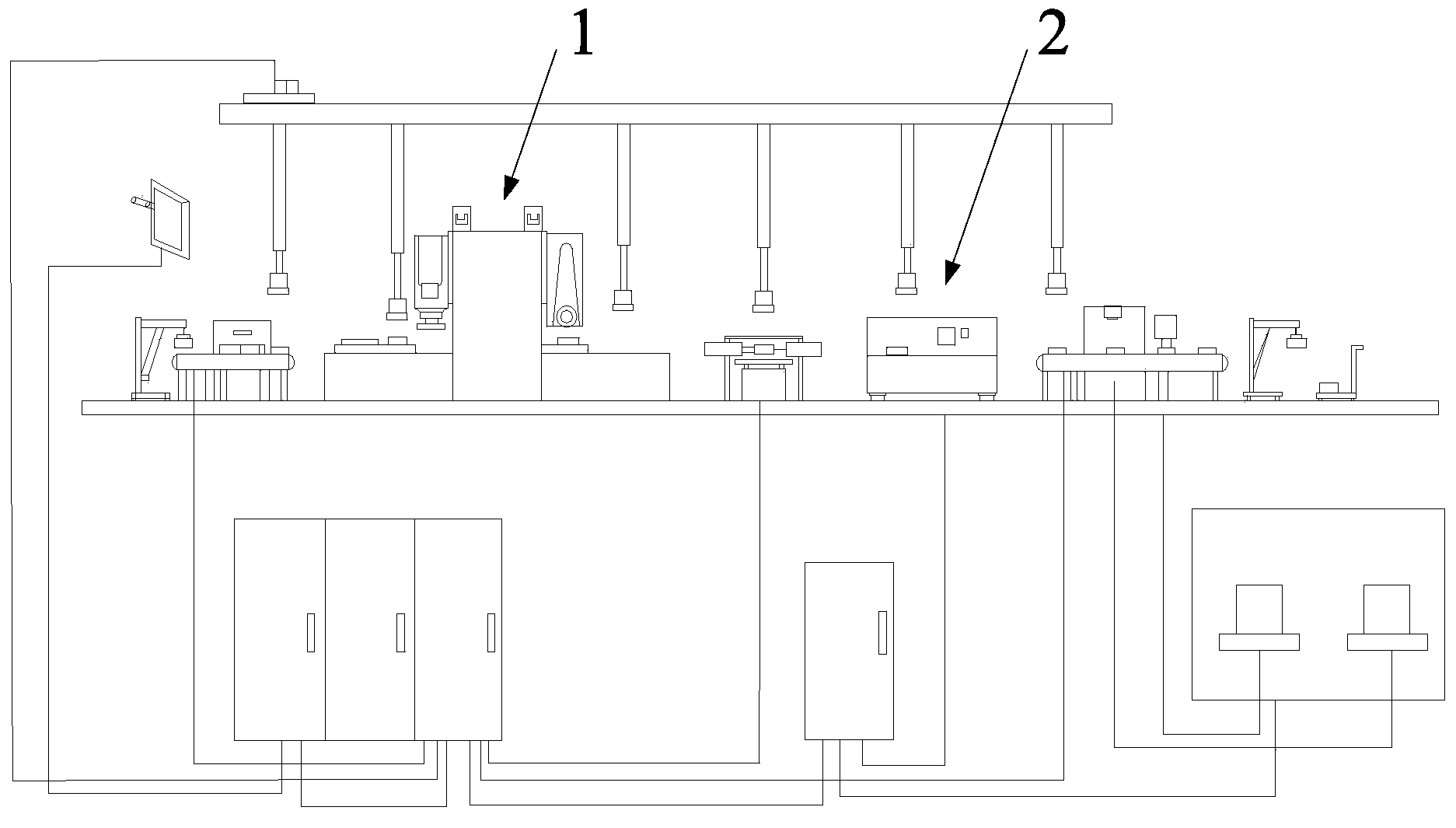

[0014] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0015] The invention provides a low-magnification tissue acid etching method, which specifically includes the steps of:

[0016] S1, sample cutting, the sample is cut by flame cutting machine;

[0017] S2. Sample cooling, the cut sample is transported to the automatic test platform by a forklift, and the automatic test platform is cooled by a cooling fan;

[0018] S3, milling and grinding process, the sample is hoisted to the milling and grinding machine for processing by means of electromagnetic lifting through automatic driving;

[0019] S4. Sample corrosion. After the milling and grinding machine finishes processing, the sample is transported to the automatic electrolytic corrosion machine, and the electrolytic corrosion machine corrodes and cleans the sample;

[0020] S5. Take photos of the samples, transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com