Preparation method of inorganic solid electrolyte membrane

An inorganic solid, electrolyte membrane technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as dendrite growth, short circuit, battery explosion, etc., to achieve a large number of charge and discharge times, large battery capacity, and stable charge and discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

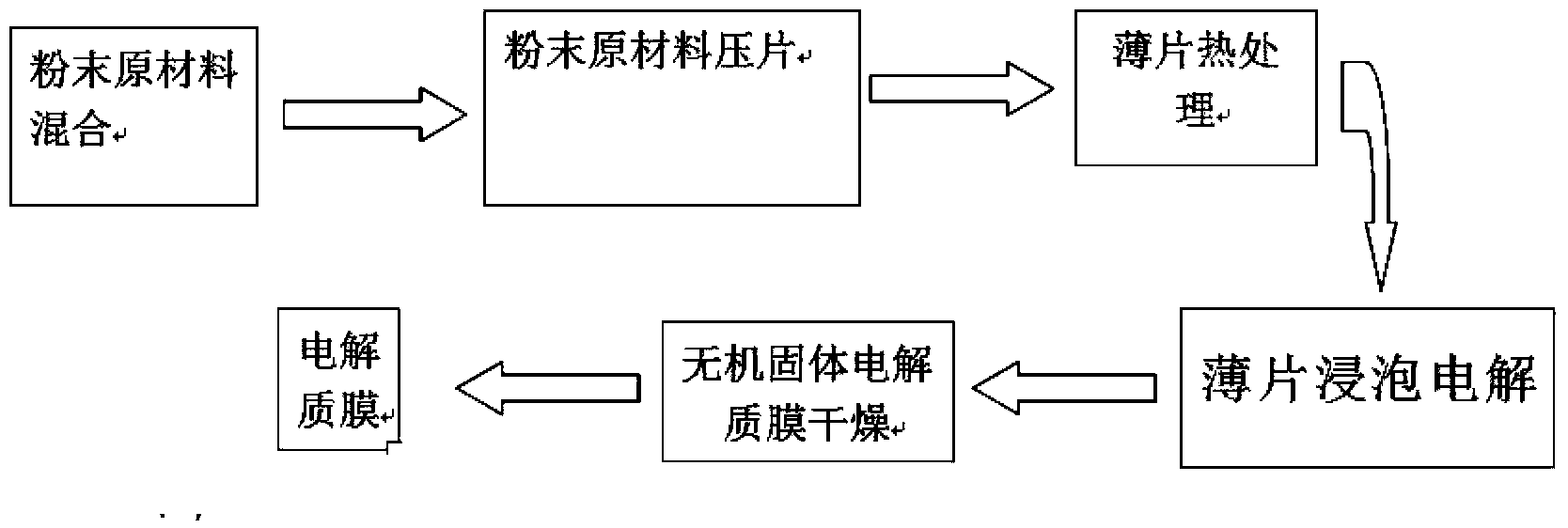

Method used

Image

Examples

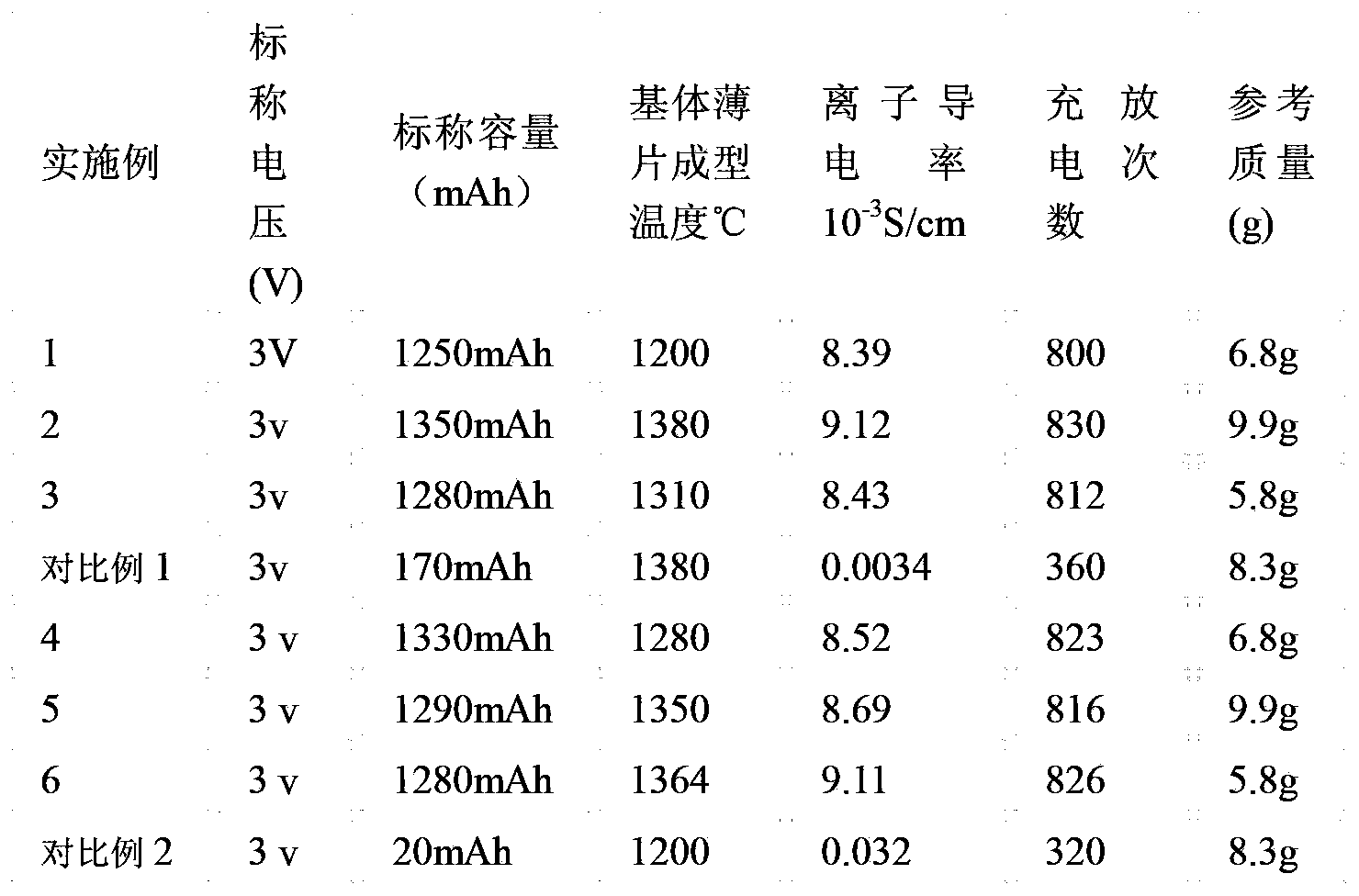

Embodiment 1

[0022] The polysiloxane resin micropowder powder with a particle size of 6um in the formula, the nano-scale lithium phosphate powder with a particle size of 8nm and diatomaceous earth are thoroughly mixed with a high-speed mixer, and then hot-pressed into a 100μm thick sheet and placed side by side. Put it into a high-temperature furnace equipped with an air extraction port at a temperature of 1200°C, and treat it for 150 minutes under the condition of a negative pressure of 0.096Mpa. The metal pipe connected to the end of the air extraction port is directly connected to a cooling device equipped with water. The top outlet is connected to the air inlet of the vacuum pump, and the air outlet is directly emptied; then the treated polysiloxane resin and lithium phosphate flakes are transported to the normal temperature air chamber without water vapor through the conveyor belt and cooled to normal temperature; The treated matrix sheet has a porosity of 78% and a pore diameter of 5u...

Embodiment 2

[0025] The polysiloxane resin powder with a particle size of 12um in the formula, the nano-sized lithium phosphate powder and diatomaceous earth with a particle size of 12nm in the formula are thoroughly mixed with a high-speed mixer, and then hot-pressed into a 600μm thick sheet, and placed Put it into a high-temperature furnace equipped with an air extraction port at a temperature of 1380 ° C, and treat it for 188 minutes under the condition of a negative pressure of 0.098Mpa. The metal pipe connected to the end of the air extraction port is directly connected to a cooling device equipped with water. The top outlet is connected to the air inlet of the vacuum pump, and the air outlet is directly emptied; then the treated polysiloxane resin and lithium phosphate flakes are transported to the normal temperature air chamber without water vapor through the conveyor belt and cooled to normal temperature; The treated matrix sheet has a porosity of 60% and a pore diameter of 3um; the...

Embodiment 3

[0028] The polysiloxane resin powder with a particle size of 7um in the formula, the nano-sized lithium phosphate powder and diatomaceous earth with a particle size of 9nm in the formula are thoroughly mixed with a high-speed mixer, and then hot-pressed into a 200μm thick sheet, and placed side by side Put it into a high-temperature furnace equipped with an air extraction port at a temperature of 1310°C, and treat it for 163 minutes under the condition of a negative pressure of 0.097Mpa. The metal pipe connected to the end of the air extraction port is directly connected to a cooling device equipped with water. The top outlet is connected to the air inlet of the vacuum pump, and the air outlet is directly emptied; then the treated polysiloxane resin and lithium phosphate flakes are transported to the normal temperature air chamber without water vapor through the conveyor belt and cooled to normal temperature; The treated matrix sheet has a porosity of 68% and a pore diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com