Thick steel sheet having superior fatigue resistance properties in direction of sheet thickness, method for producing same, and fillet welded joint using said thick steel sheet

A technology of plate thickness direction and thick steel plate, which can be used in manufacturing tools, welding equipment, arc welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

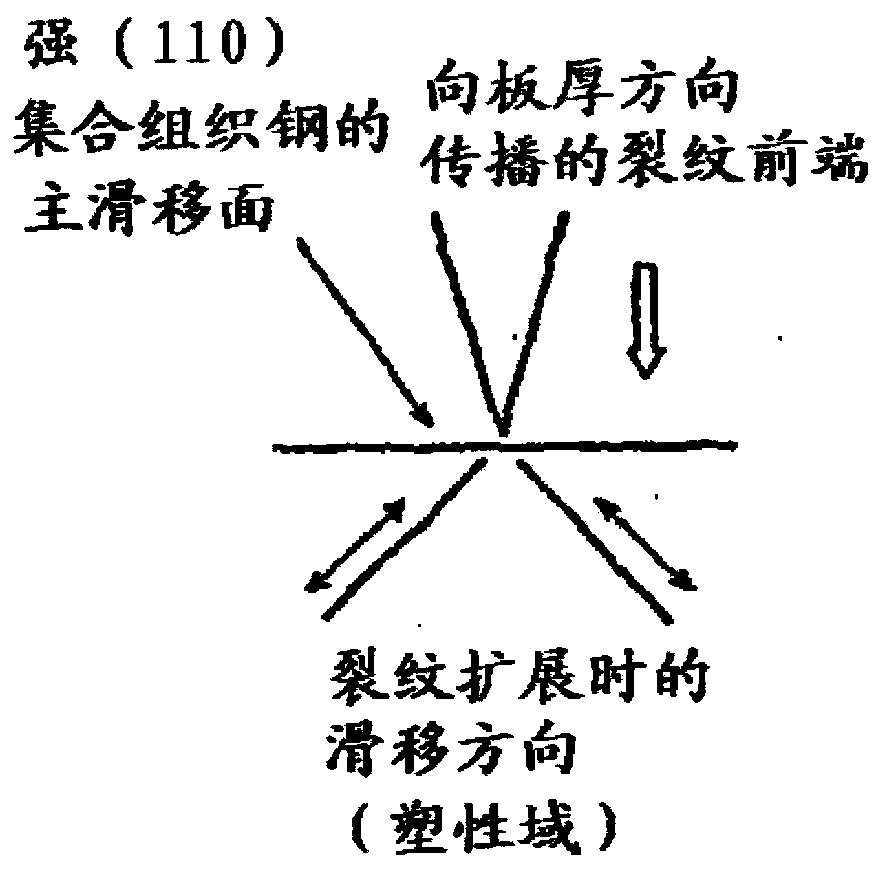

Method used

Image

Examples

Embodiment 1

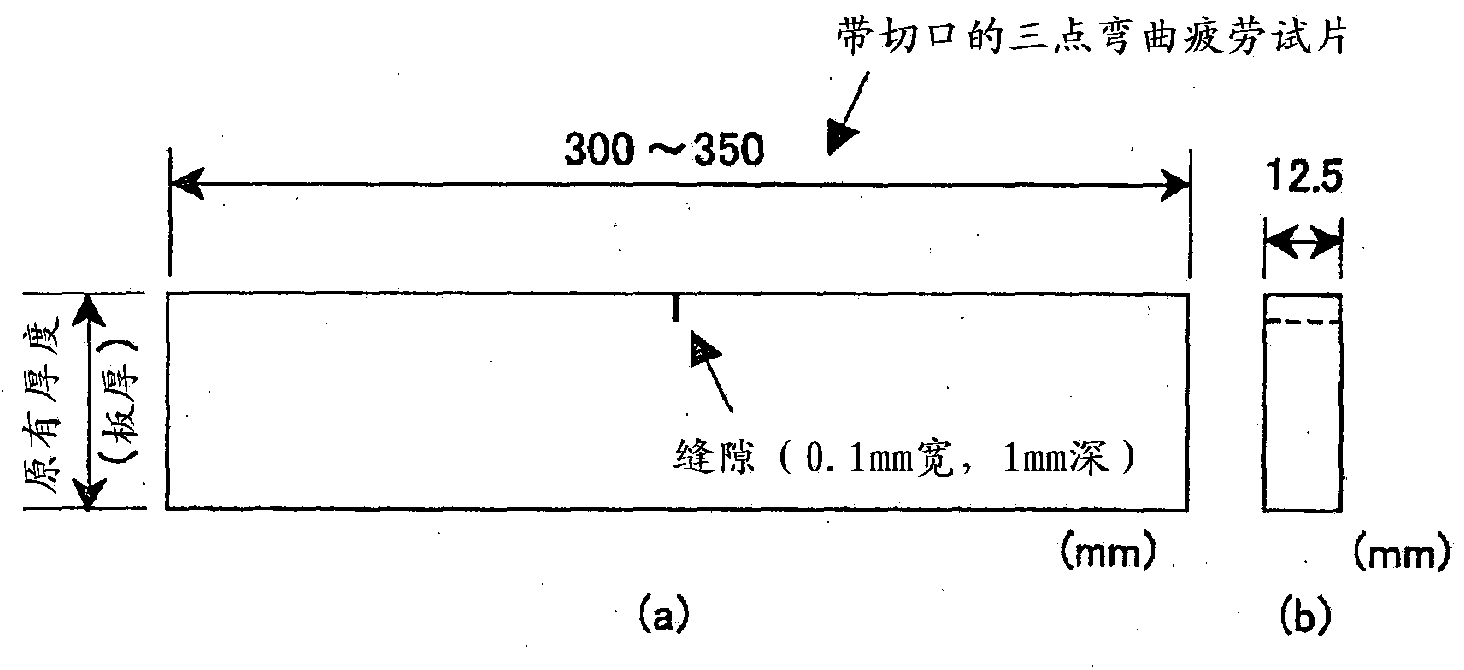

[0090] The steel materials having the compositions shown in Table 1 were hot-rolled under the conditions shown in Table 2 to form thick steel plates with a plate thickness of 55 to 70 mm. These thick steel plates were subjected to residual stress measurement, tensile test, toughness test, and fatigue test. The test method is as follows.

[0091] (1) Determination of residual stress

[0092] A test piece (size: plate thickness (original thickness of the steel plate) × 12.5mm × 300mm [dimension in the direction of plate thickness × dimension in the direction perpendicular to rolling × direction of rolling) is taken from the obtained thick steel plate for residual stress measurement by X-rays Dimensions]), after performing electrolytic polishing on the measurement surface [12.5mm×300mm surface], measure the residual stress in the thickness direction by X-ray at a pitch of 4mm along the thickness direction. The number of lines measured at a pitch of 4 mm along the plate thicknes...

Embodiment 2

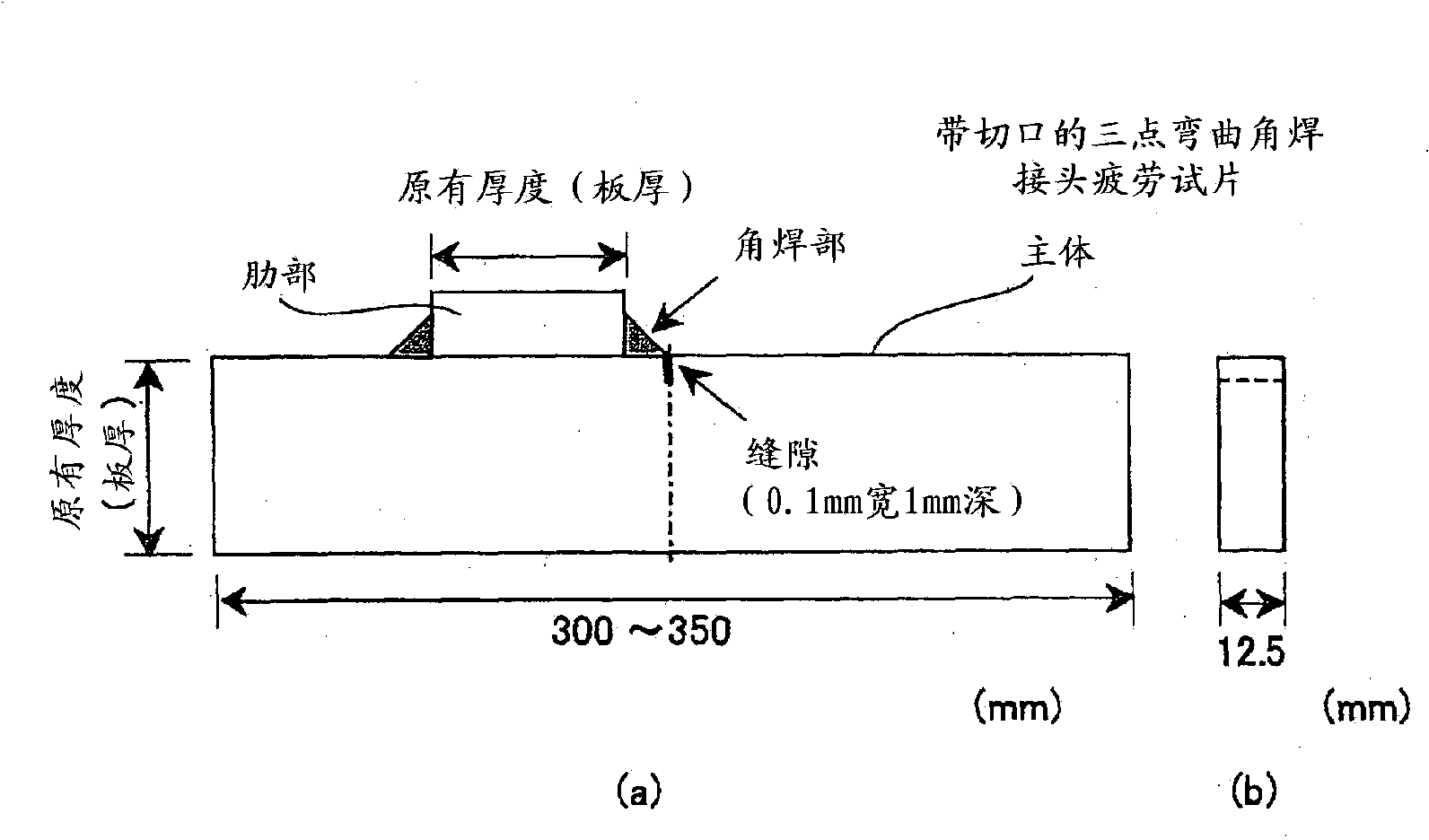

[0102] Fillet welds were produced using a thick steel plate 2 having a chemical composition shown in Table 3, manufactured under the manufacturing conditions shown in Table 4, and having a thickness of 55 to 70 mm with excellent fatigue properties in the thickness direction of the plate and having the characteristics shown in Table 4. head, use figure 2 The three-point bending fatigue test is carried out on the fatigue test piece of the three-point bending fillet welded joint with the shape shown. The test method for confirming the structure, mechanical properties, and fatigue properties in the plate thickness direction of the thick steel plate 2 was performed in the same manner as in Example 1.

[0103] Using the thick steel plate 2 whose characteristics were confirmed by the above tests, in Figure 4 Fillet welded joints were fabricated under the conditions shown, and fatigue tests were performed. As a fatigue test piece, use figure 2 Fatigue test pieces of three-point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com