Etching solution for performing wet etching on lanthanum nickelate film and ferroelectric film/lanthanum nickelate composite film and preparation method thereof

A ferroelectric thin film and wet etching technology, which is applied in the direction of chemical instruments and methods, surface etching compositions, etc., can solve the problem of small side etching ratio, etc., and achieve the effect of clear edge, wide application, and steep interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

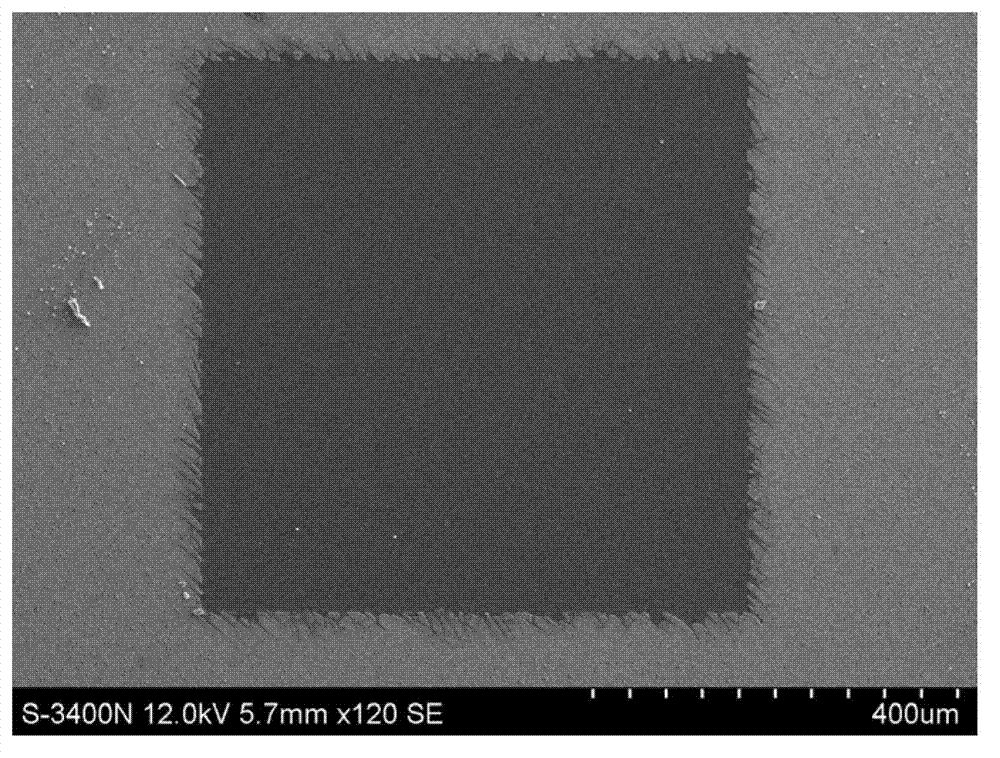

[0027] The corrosion solution described in this embodiment is used for LNO / SiO 2 The LNO film in the Si substrate is etched, and the LNO film in the substrate has good crystallization and a thickness of 600nm.

[0028] (1) Preparation of corrosion solution

[0029] Using hydrogen peroxide, nitric acid, hydrofluoric acid and deionized water as raw materials, the volume ratio of deionized water, hydrogen peroxide, nitric acid and hydrofluoric acid is: deionized water: hydrogen peroxide: nitric acid: hydrofluoric acid = 1: 2.5: 0.5: 0.12 , at normal temperature (22°C) and normal pressure, mix the deionized water and hydrogen peroxide measured according to the above volume ratio evenly, then add the measured nitric acid and mix well, then add the measured hydrofluoric acid and mix well, That is, a corrosive solution is formed.

[0030] (2) Etching of LNO film

[0031] Apply photoresist (negative, L-300) on LNO / SiO by spin coating 2 / Si substrate, through pre-baking (95°C, 5 mi...

Embodiment 2

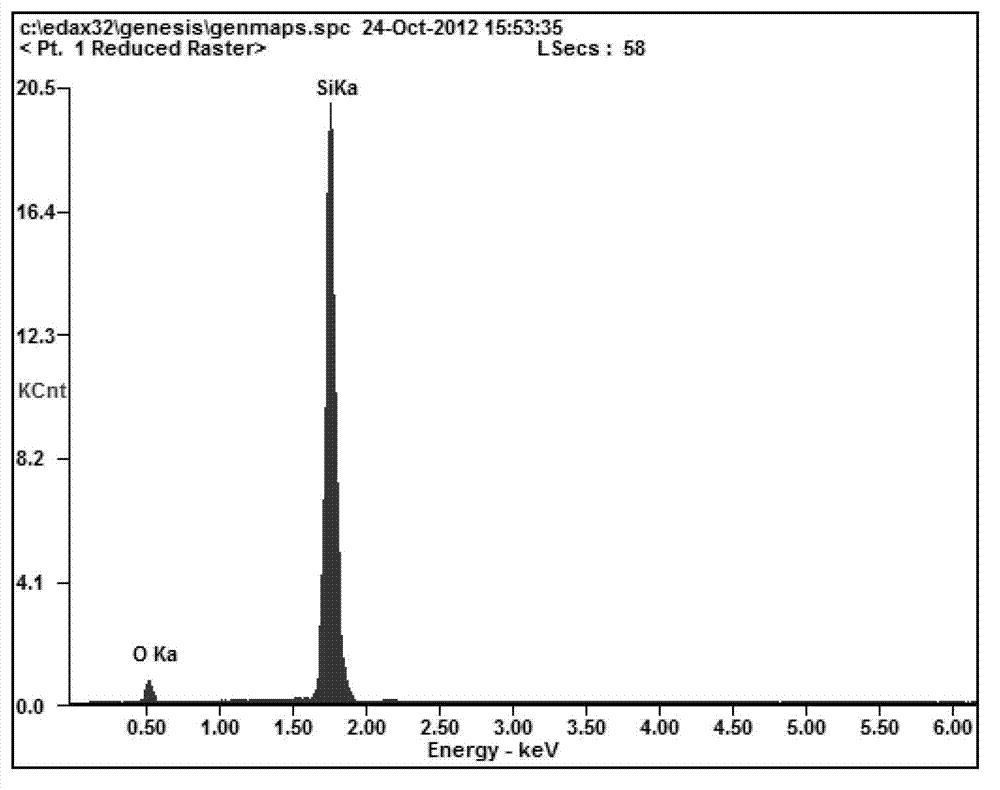

[0034] The corrosion solution described in this embodiment is used for BST / LNO / SiO 2 The BST / LNO composite film on the Si substrate is etched, and the BST / LNO composite film in the substrate is well crystallized, wherein BST (barium strontium titanate Ba 1-x Sr x TiO 3 Abbreviation) layer thickness is 800nm, LNO layer thickness is 250nm.

[0035] (1) Preparation of corrosion solution

[0036] Using hydrogen peroxide, nitric acid, hydrofluoric acid and distilled water as raw materials, the volume ratio of distilled water, hydrogen peroxide, nitric acid and hydrofluoric acid is: distilled water: hydrogen peroxide: nitric acid: hydrofluoric acid = 1:2:0.5:0.1, at room temperature (18°C ), under normal pressure, mix the deionized water and hydrogen peroxide measured according to the above volume ratio evenly, then add the measured nitric acid and mix evenly, and then add the measured hydrofluoric acid and mix evenly to form a corrosion solution.

[0037] (2) Etching of BST / LNO...

Embodiment 3

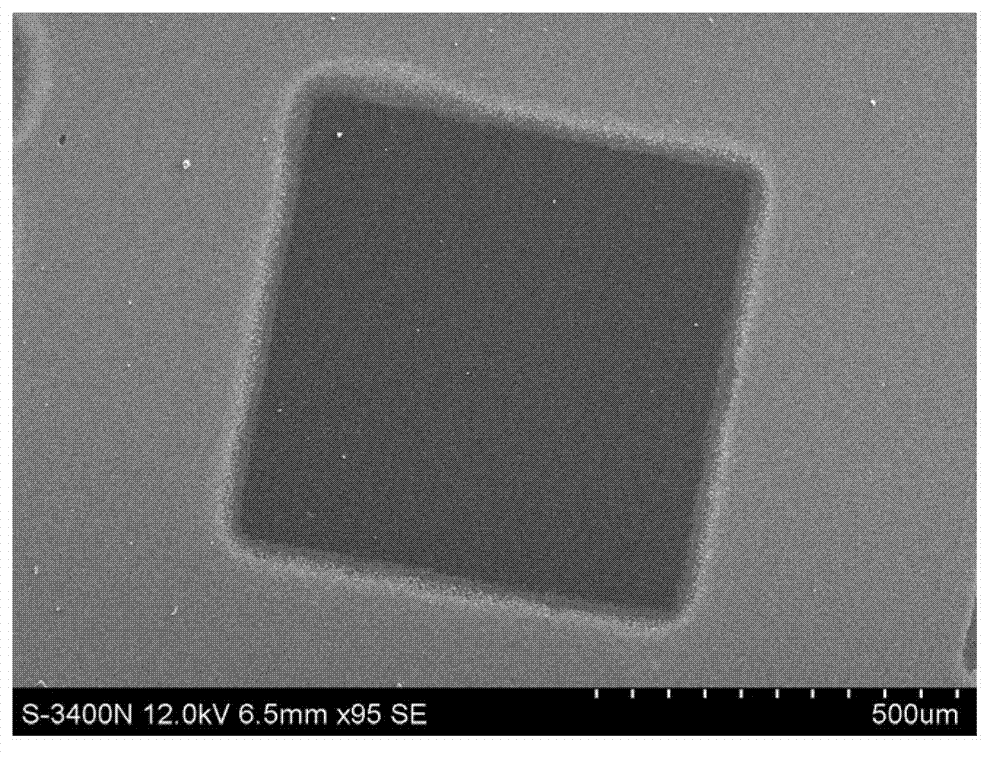

[0041] The etching solution described in this embodiment is used for LNO / Pt / Ti / SiO 2 The LNO film in the Si substrate is etched, and the LNO film in the substrate has good crystallization and a thickness of 400nm.

[0042] (1) Preparation of corrosion solution

[0043] Using hydrogen peroxide, nitric acid, hydrofluoric acid and deionized water as raw materials, the volume ratio of deionized water, hydrogen peroxide, nitric acid and hydrofluoric acid is: deionized water: hydrogen peroxide: nitric acid: hydrofluoric acid = 1: 2.5: 1: 0.06 , at normal temperature (26°C) and normal pressure, mix the deionized water and hydrogen peroxide measured according to the above volume ratio evenly, then add the measured nitric acid and mix well, then add the measured hydrofluoric acid and mix well, That is, a corrosive solution is formed.

[0044] (2) Etching of LNO film

[0045] Apply photoresist (negative, L-300) on LNO / Pt / Ti / SiO by spin coating 2 / Si substrate, through pre-baking (95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com