Dog food capable of improving antioxidant ability and intestinal health conditions of dogs and preparation method thereof

A technology with antioxidant capacity and intestinal health, which can be used in applications, animal feed, animal feed, etc., and can solve the problems of difficult dog food, decreased viscoelasticity of flour, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

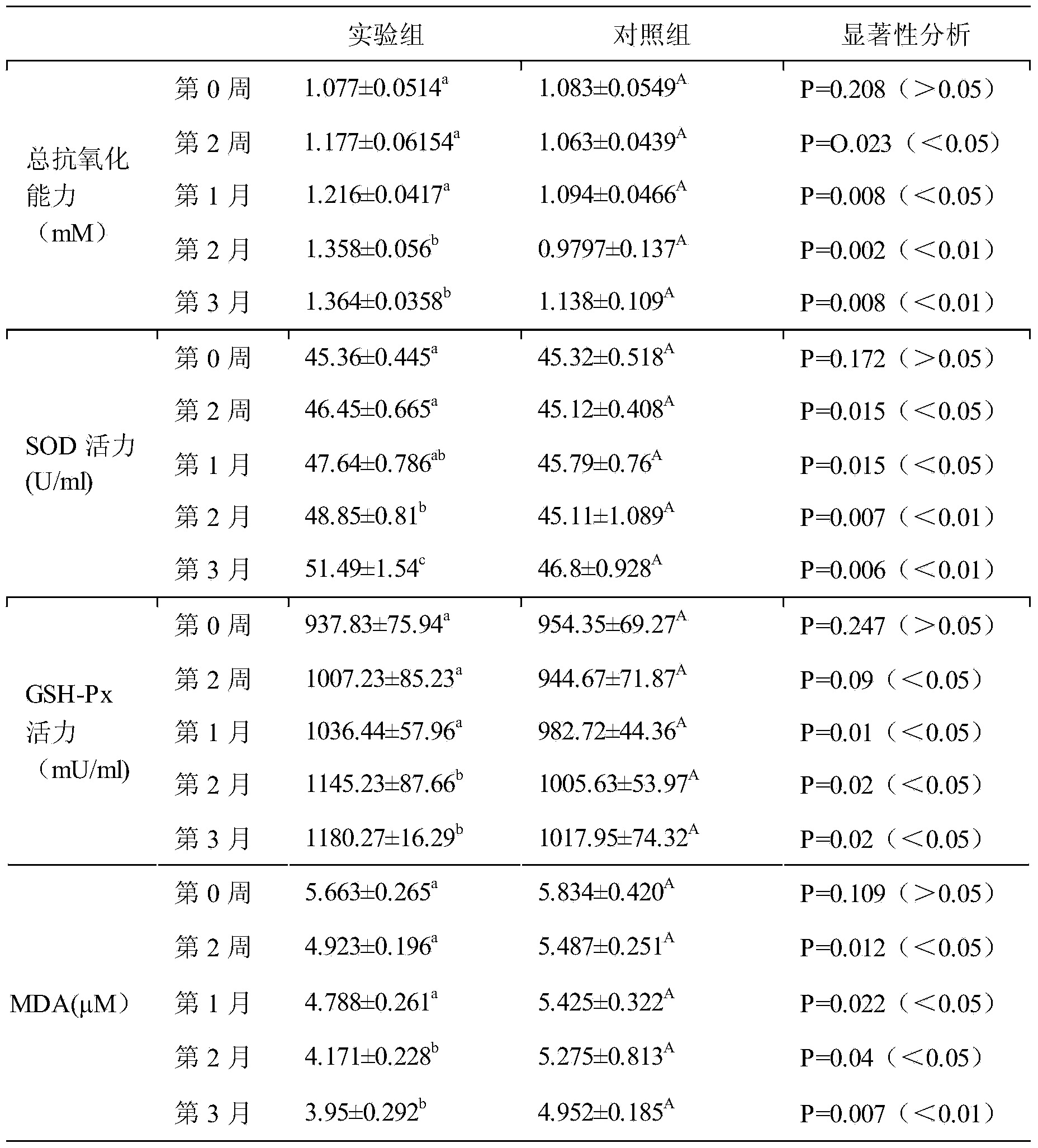

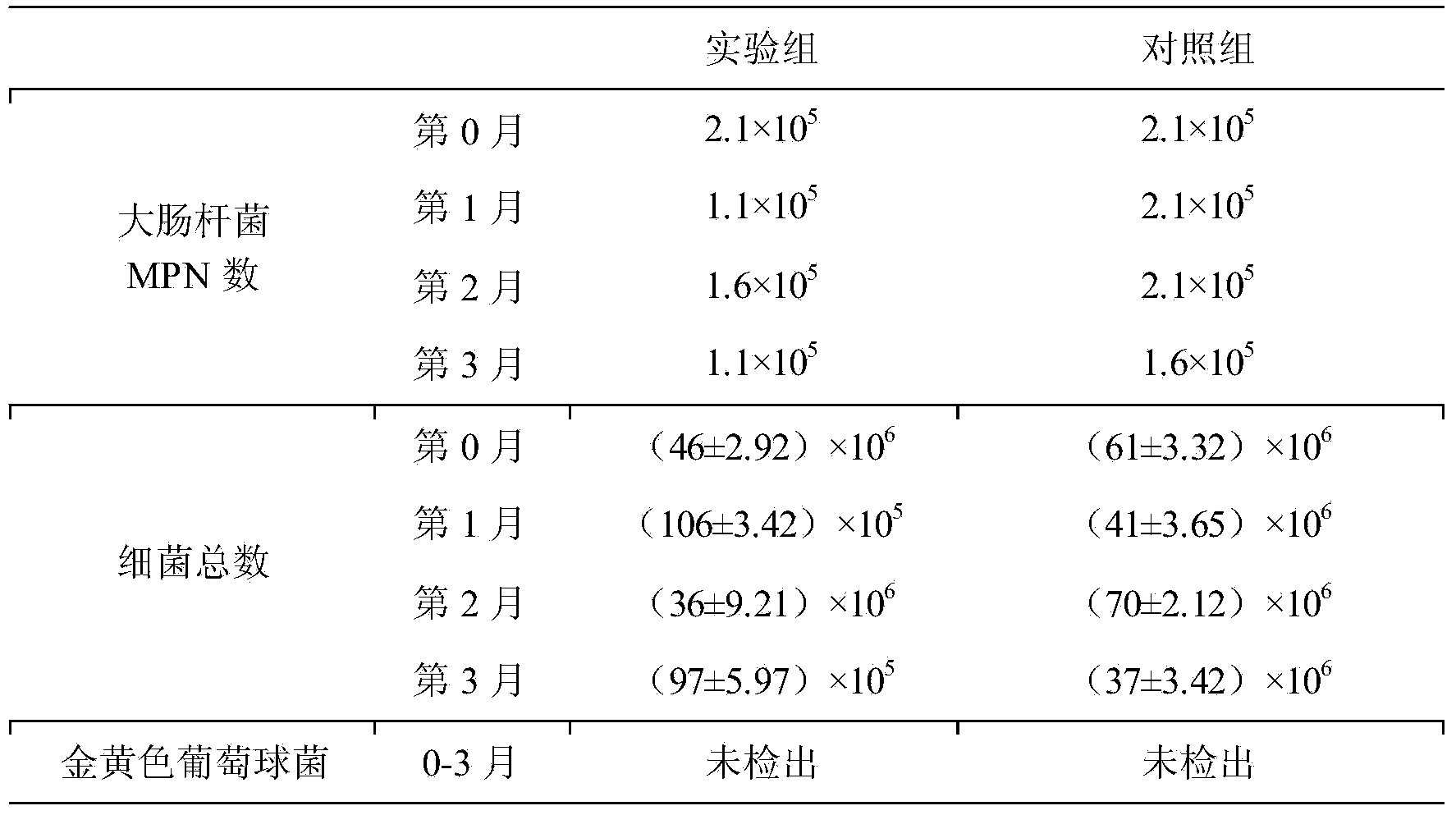

Examples

Embodiment 1

[0019] (1) Material formula: polished rice 120g, soybean meal 100g, corn 305g, wheat flour 100g, fish meal 190g, yeast powder 80g, calcium hydrogen phosphate 10g, salt 5g, vitamin premix (Cangzhou Maoyuan Animal Husbandry Co., Ltd., electrolytic multidimensional, 227g) 2g, mineral premix (Heilongjiang Julong Feed Technology Co., Ltd., trace elements for animals and pets, 1000g) 2g, potassium sorbate 1g, tea polyphenol 5g. The above-mentioned materials are pulverized by an ultrafine pulverizer until they can pass through a 60-mesh sieve;

[0020] (2) Mixing: Mix the pulverized materials evenly through a ribbon mixer;

[0021] (3) Preparation: add water to the mixed material to adjust the moisture content to 25%;

[0022] (4) Extrusion and puffing: the temperature of the three-stage barrel is 80°C, 125°C, and 135°C; the moisture content of the material is 25%; the screw speed is 180r / min; the mixed material is put into the feeder and passed through the feeder After entering th...

Embodiment 2

[0028] (1) Material formula: polished rice 120g, soybean meal 150g, corn 255g, wheat flour 100g, fish meal 190g, yeast powder 80g, calcium hydrogen phosphate 10g, salt 5g, vitamin premix (Cangzhou Maoyuan Animal Husbandry Co., Ltd., electrolytic multidimensional, 227g) 2g, mineral premix (Heilongjiang Julong Feed Technology Co., Ltd., trace elements for animals and pets, 1000g) 2g, potassium sorbate 1g, tea polyphenol 5g. The above-mentioned materials are pulverized by an ultrafine pulverizer until they can pass through a 60-mesh sieve;

[0029] (2) Mixing: Mix the pulverized raw materials evenly through a ribbon mixer;

[0030] (3) Preparation: add water to the mixed raw materials to adjust the moisture content to 25%;

[0031] (4) Extrusion and puffing: the temperature of the three-stage barrel is 80°C, 125°C, and 135°C; the moisture content of the material is 25%; the screw speed is 180r / min; the mixed material is put into the feeder and passed through the feeder After en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com