Hernia mesh plug prepared from modified polypropylence fiber single silk mesh

A technology of polypropylene fiber and screen cloth, which is applied in the field of medical devices, can solve the problems of increasing the difficulty and risk of rehabilitation, remaining chronic pain, and easy recurrence, and achieves the effects of simple disinfection, reduced production cost, and reduced recurrence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

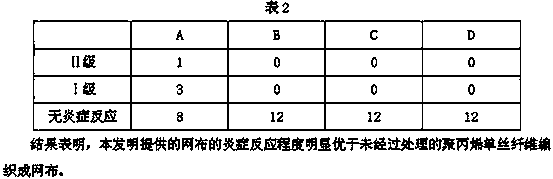

[0029] The hernia mesh plug made of modified polypropylene fiber monofilament mesh is made of modified polypropylene fiber monofilament mesh obtained by surface treatment, and the surface treatment method of polypropylene fiber monofilament mesh is first Treat with an oxidizing agent for 40 minutes, and then carry out surface coating treatment with an organic solvent overnight; the oxidizing agent is potassium permanganate whose concentration is 1% by weight percentage; the organic solvent used in the surface coating treatment is a concentration by weight percentage 5% ethanol solution containing methyl ethyl cellulose.

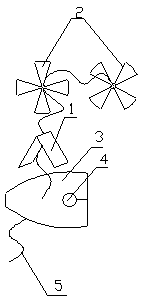

[0030] The filling net plug includes a conical net 1, a double-layer petal-shaped net 2 and a fixed piece 3. The conical net 1 is in the shape of a polygonal pyramid; the double-layer petal-shaped net 2 is composed of two inner and outer petal-shaped nets connected; Between the inner and outer layers of petal-shaped mesh, between the double-layer petal-shaped...

Embodiment 2

[0032] The hernia mesh plug made of modified polypropylene fiber monofilament mesh is made of modified polypropylene fiber monofilament mesh obtained by surface treatment, and the surface treatment method of polypropylene fiber monofilament mesh is first Treat with an oxidizing agent for 40 minutes, and then carry out surface coating treatment with an organic solvent overnight; the oxidizing agent is potassium permanganate whose concentration is 1% by weight percentage; the organic solvent used in the surface coating treatment is a concentration by weight percentage It is a 5% ethanol solution containing ethylene-vinyl alcohol-ethylene acetate.

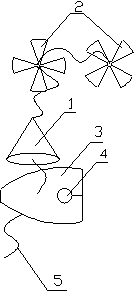

[0033] The filling net plug includes a conical net 1, a double-layer petal-shaped net 2 and a fixed piece 3. The conical net 1 is in the shape of a cone; the double-layer petal-shaped net 2 is composed of two layers of petal-shaped nets inside and outside; Between the two-layer petal-shaped mesh, between the double-layer petal-shaped ...

Embodiment 3

[0035] The hernia mesh plug made of modified polypropylene fiber monofilament mesh is made of modified polypropylene fiber monofilament mesh obtained by surface treatment, and the surface treatment method of polypropylene fiber monofilament mesh is first Treat with an oxidizing agent for 40 minutes, and then carry out surface coating treatment with an organic solvent overnight; the oxidizing agent is potassium permanganate whose concentration is 1% by weight percentage; the organic solvent used in the surface coating treatment is a concentration by weight percentage It is an ethanol solution of 2.5% polyacrylonitrile+polyurethane with a concentration of 2.5% by weight.

[0036]The filling net plug includes a conical net 1 and a circular fixing piece 6; the bottom surface of the conical net 1 is connected to the center of the circular fixing piece 6 by sewing. The hernia mesh plug is made of medical polypropylene monofilament mesh. The pore size of the mesh structure of the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bursting strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com