Remover and removal method for sulfuretted hydrogen in low-water cut crude oil associated gas

A technology for hydrogen sulfide and removing agent, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of high space cost and other problems, and achieve the effects of high removal efficiency, low dosage and irreversible reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

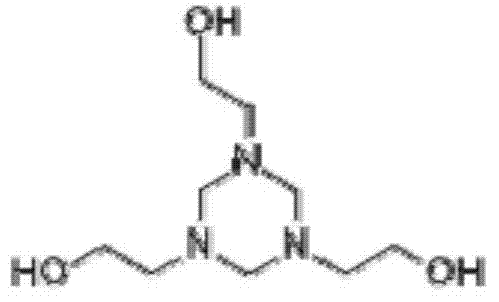

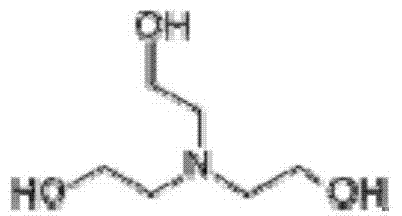

[0029] A hydrogen sulfide removal agent in low-water crude oil associated gas is a hydroxyethyl polymer, and the weight percentage of its components is 85% of hydroxyethyl hexahydro-s-triazine, 6% of ethylene glycol, and di Methylformamide 9%. The hydrogen sulfide remover used is prepared by mechanically mixing hydroxyethyl hexahydro-s-triazine, ethylene glycol and dimethylformamide.

Embodiment 2

[0031] A method for removing hydrogen sulfide in low-water crude oil associated gas, which is characterized in that a hydrogen sulfide remover is added to the inlet of the crude oil transport pump on the platform, the hydrogen sulfide remover is a hydroxyethyl polymer, and the hydrogen sulfide remover is The hydroxyethyl polymer contains 80% of hydroxyethylhexahydro-s-triazine, 10% of ethylene glycol and 6% of dimethylformamide in weight percent of each component. The hydrogen sulfide removal agent is added in an amount to achieve a concentration of 50-300ppm.

Embodiment 3

[0033] Preparation and application of hydrogen sulfide removal agent in crude oil with low water content

[0034] Component distribution (by weight): ethylene glycol 5%, hydroxyethylhexahydro-s-triazine 90%, dimethylformamide 5%.

[0035] Preparation method: mechanically mix according to the formula

[0036] Operation object: crude oil with low water content on offshore platforms

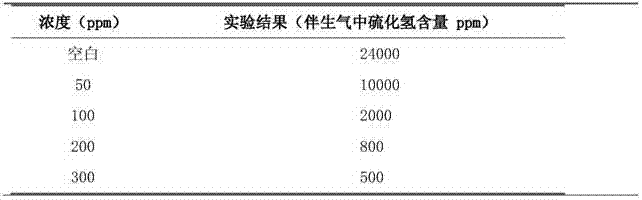

[0037] Operation method: Add hydrogen sulfide removers with different concentrations into the sampler, collect 500ml of oil-water mixture (crude oil contains 3% water) at the sampling end of crude oil output, oscillate and shake well, and after standing for 1 minute, use a gas sampler to analyze the associated hydrogen sulfide. The concentration of hydrogen sulfide in the gas.

[0038] The results are shown in Table 1.

[0039] Table 1 Desulfurization effects of different concentrations of hydrogen sulfide removal agents

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com