Preparation method of metal organic framework membrane for CO2 separation

A metal-organic framework and seed crystal technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems that are not conducive to membrane adhesion, and achieve the effect of wide film-forming conditions and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of Metal-Organic Framework Membrane-CAU-1 Membrane by Single-Solvent Secondary Seeding Method

[0034] (1) Preparation of seed crystals: AlCl 3 ·6H 2 O (2.261g, 9.36mmol), H 2 N-H 2 Mix BDC (0.568g, 3.14mmol) and methanol (30mL) evenly, ultrasonically oscillate until the solid is completely dissolved, put it into a polytetrafluoro-lined stainless steel kettle, react at 125°C for 5h, and centrifuge at 10,000rpm for 10min after the reaction is completed , remove the supernatant, and wash the lower layer with deionized water first (every 0.5g of the lower layer is dispersed in 2000ml of deionized water) for 12h, then stir and wash with methanol (every 0.5g of the lower layer is dispersed in 500ml of methanol) for 12h, and wash away unreacted The components of the reaction solution were vacuum-dried at 100°C for 3 days to obtain CAU-1 seed crystals.

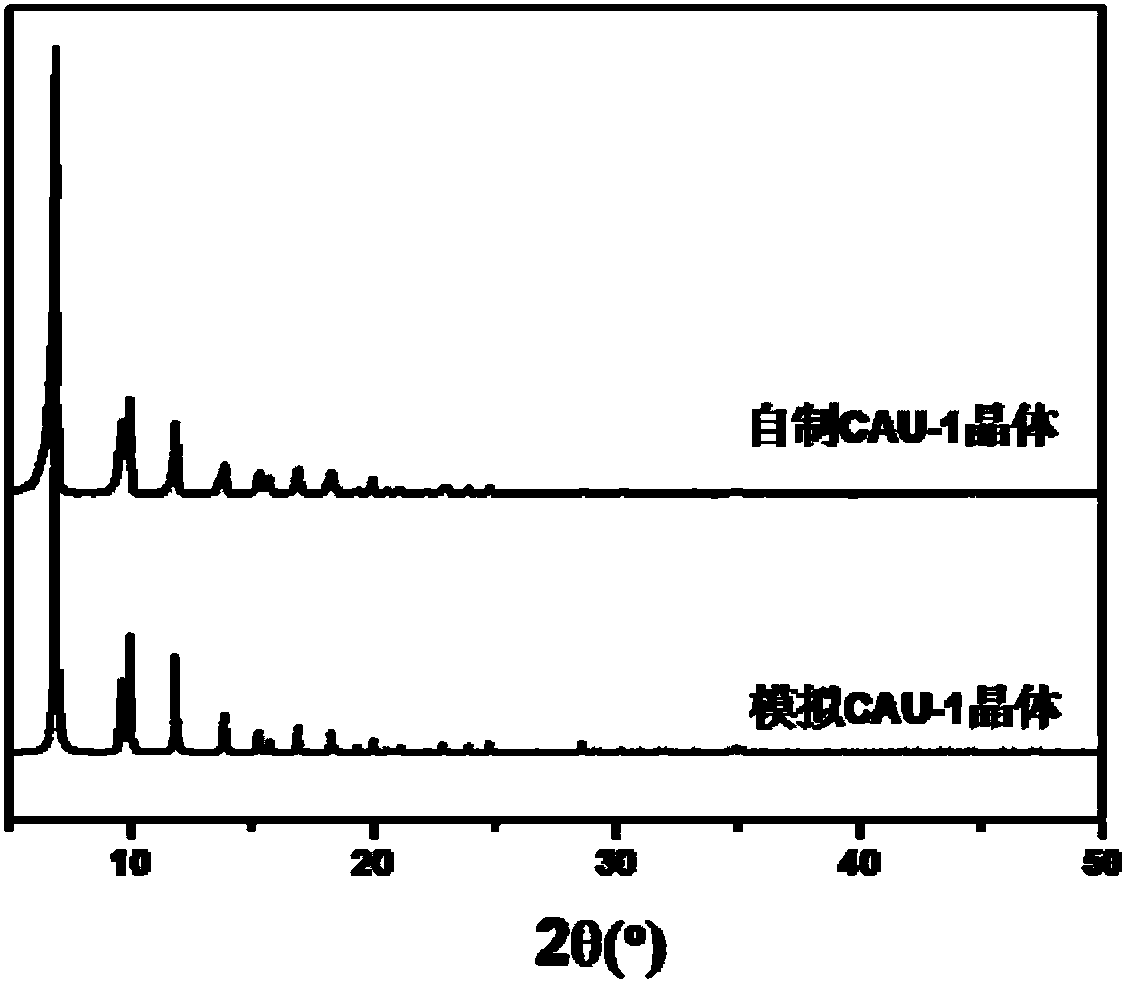

[0035] The synthesized CAU-1 crystals were subjected to XRD ( figure 1 ) and SEM ( figure 2 ) r...

Embodiment 2

[0042] Example 2 Preparation of Metal Organic Framework Membrane-CAU-1 Membrane by Mixed Solvent Secondary Seeding Method

[0043] The carrier tube coated with the seed crystal was prepared according to the method of (1)-(3) in Example 1.

[0044] AlCl 3 ·6H 2 O (1.01g, 4.18mmol) and H 2 N-H 2 BDC (0.25g, 1.38mmol) was dissolved in a mixed solution of 20ml of methanol and ethanol (the volume ratio of methanol and ethanol was 1:2) by ultrasonic vibration to configure the film-forming solution. Transfer the film-forming solution into a stainless steel kettle lined with PTFE, and at the same time put the prepared pre-coated carrier tube with seed crystals vertically into the kettle to ensure that the film-forming solution covers the carrier tube and seal the The reaction kettle was placed in an oven at 125°C for 12 hours, and the carrier tube was stirred and washed with methanol for 5 times. membrane.

[0045] Mixed gas test: put the synthesized metal-organic framework memb...

Embodiment 3

[0049] Example 3 Preparation of Metal Organic Framework Membrane-CAU-1 Membrane by Mixed Solvent In-situ Growth Method

[0050] The α-Al2O3 carrier tube was prepared according to the method in (2) of Example 1 for future use.

[0051] AlCl 3 ·6H 2 O (1.01g, 4.18mmol) and H 2 N-H 2 BDC (0.25g, 1.38mmol) was dissolved in a mixed solution of 20ml of methanol and ethanol (the volume ratio of methanol and ethanol was 1:2) by ultrasonic vibration to configure the film-forming solution. Transfer the film-forming solution into a stainless steel kettle lined with polytetrafluoroethylene, and at the same time put the prepared α-Al 2 o 3 Put the carrier tube vertically into the kettle, make sure that the film-forming solution covers the carrier tube, put the closed reaction kettle in an oven at 125°C for 12 hours, stir and wash the carrier tube with methanol for 5 times, the first two times are 5 hours, and then Wash for 12 hours each time three times, and then dry in a vacuum oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Permeation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com