Comprehensive utilization method of coal-based oil residue

A coal-based oil and tar technology, applied in the petroleum industry, coking carbonaceous materials, coke ovens, etc., can solve the problems of incomplete filtration, waste, complex recovery process, etc., achieve short material residence time, avoid separation steps, heat High solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

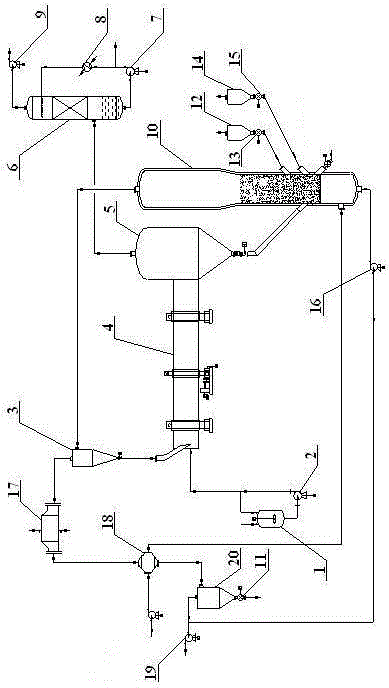

[0023] Such as figure 1 As shown, a comprehensive utilization method of coal-based oil residue:

[0024] Send the coal-based oil residue into the beating tank 1 to beat it into a paste, and then send the pasty coal-based oil residue into the rotary pyrolysis furnace 4 through the feeding system 2 at the bottom of the beating tank 1; The feed port is connected with the feed port of the primary cyclone separator 3 of the circulating fluidized bed hot blast stove 10, and the hot solid heat carrier from the primary cyclone separator 3 merges with the coal-based oil residue at the feed end of the rotary pyrolysis furnace 4, Under the action of the rotation of the rotary pyrolysis furnace 4, the hot solid heat carrier and the coal-based oil residue are mixed, pyrolyzed and moved, and the pyrolyzed solids and gases are discharged from the discharge end of the rotary pyrolysis furnace 4 and enter the separator Carry out gas-solid separation in 5:

[0025] The gas part is pyrolysis g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com